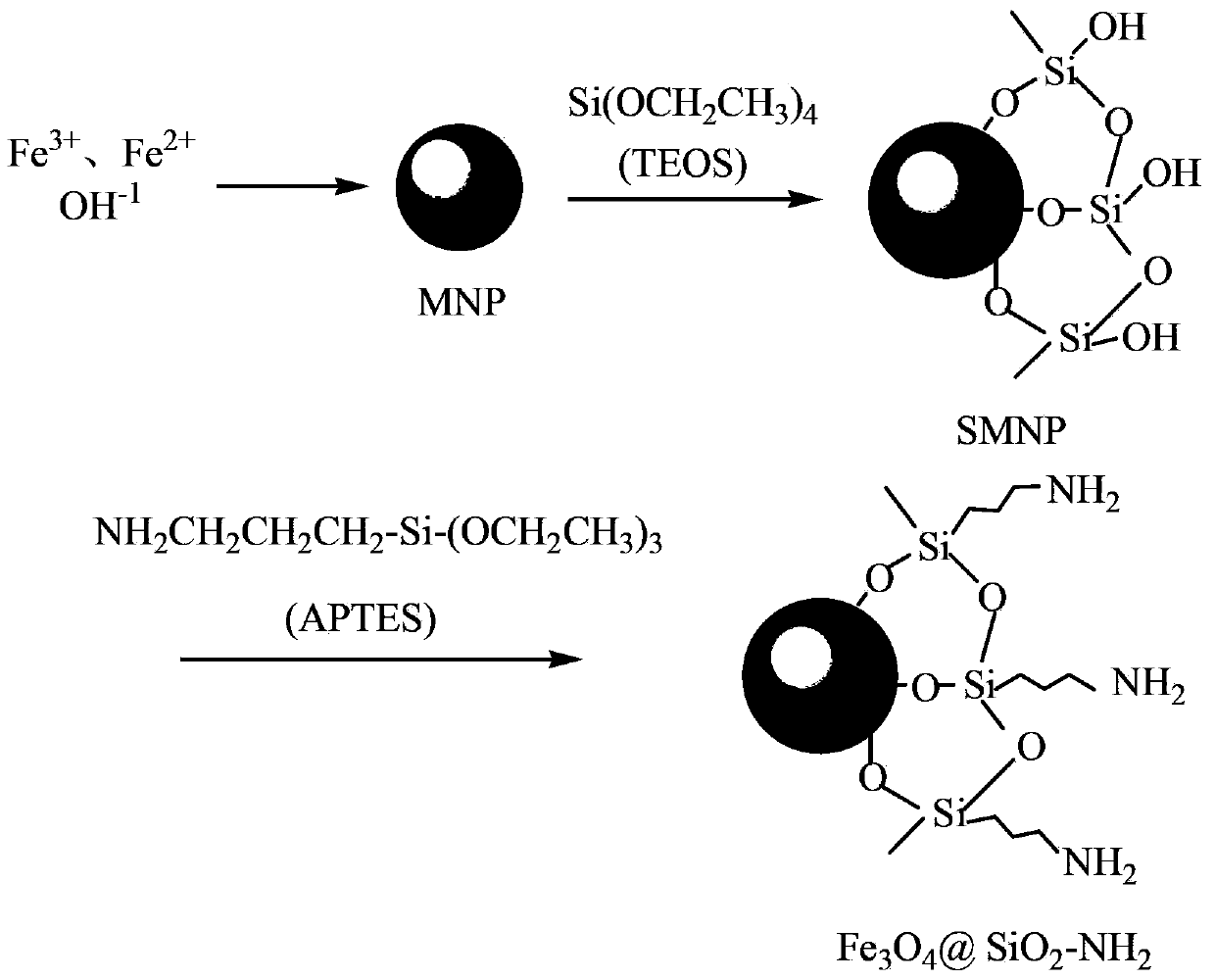

Preparation method of magnetic Fe3O4@SiO2-NH2 nanoparticles

A technology of fe3o4sio2-nh2 and nano-microspheres, which is applied to the magnetic properties of inorganic materials, fixed on or in the inorganic carrier, and can solve the problems of magnetic nanoparticle agglomeration and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

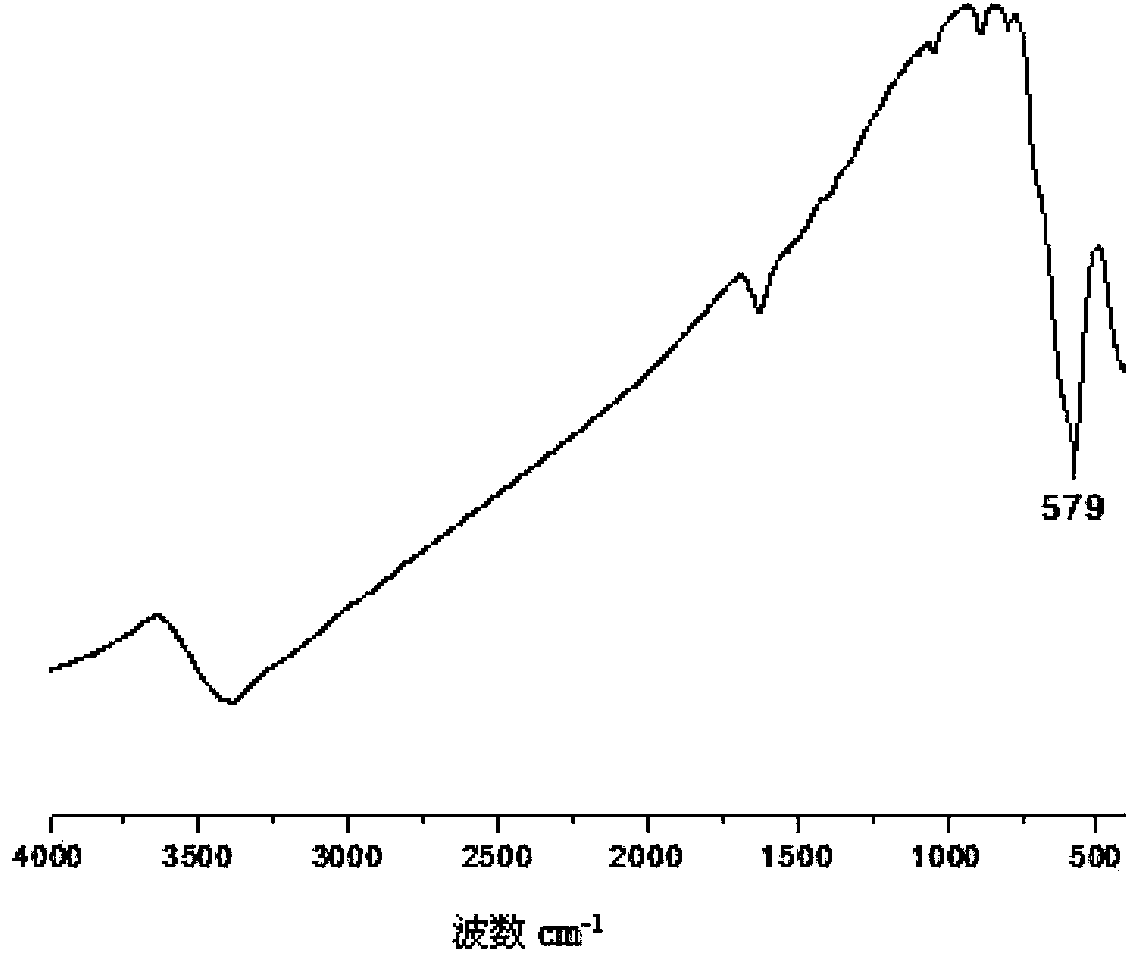

[0052] 1) Magnetic Fe 3 o 4 Synthesis of Nanospheres:

[0053] A certain amount of water (similar to the size of the container) was added into a round bottom flask, the reaction system was protected by argon, and the oxygen in the water was removed by the vacuum deaeration method with the help of liquid nitrogen, and 4.0g FeCl 2 4H 2 O and 10.8 g FeCl 3 ·6H 2 O in the container, protected by argon, heated to 80°C, after the reaction system is uniform, add 29wt% 50ml ammonia solution drop by drop to turn black, continue to heat for 20-30min, magnetically adsorb, and then repeat with distilled water and absolute ethanol Wash several times until the washing solution is neutral, and evaporate to dryness to obtain the black product Magnetic Fe 3 o 4 Nanoparticles (MNPs).

[0054] 2) Magnetic Fe 3 o 4 SiO 2 Synthesis of Nanospheres:

[0055] The magnetic Fe of step 1) 3 o 4 Put 1.0g of nanospheres in a 250ml two-neck flask, add 80ml of absolute ethanol, and 20ml of wate...

Embodiment 2

[0059] 1) Magnetic Fe 3 o 4 Synthesis of Nanospheres:

[0060] A certain amount of water (similar to the size of the container) was added into a round bottom flask, the reaction system was protected by argon, and the oxygen in the water was removed by the vacuum deaeration method with the help of liquid nitrogen, and 3.5gFeCl 2 4H 2 O and 9.45gFeCl 3 ·6H 2 O in the container, protected by argon, heated to 70°C, after the reaction system is uniform, add 29wt% 37.5ml ammonia solution drop by drop to turn black, continue heating for 20min, magnetic adsorption, and then wash repeatedly with distilled water and absolute ethanol Several times until the washing solution is neutral, evaporate to dryness to obtain a black product, magnetic Fe 3 o 4 Nanoparticles (MNPs).

[0061] 2) Magnetic Fe 3 o 4 SiO 2 Synthesis of Nanospheres:

[0062] The magnetic Fe of step 1) 3 o 4 Put 0.1g of nanospheres into a 250ml two-necked flask, add 80ml of absolute ethanol, and 20ml of water...

Embodiment 3

[0066] 1) Add a certain amount of water (similar to the size of the container) into the round bottom flask, protect the reaction system with argon gas, use liquid nitrogen to freeze and thaw repeatedly, remove oxygen in the water by vacuum deaeration method, and dissolve 4.5gFeCl 2 4H 2 O and 12.15 g FeCl 3 ·6H 2 O in the container, protected by argon, heated to 90°C, after the reaction system is uniform, add 29wt% 62.5ml ammonia solution drop by drop to turn black, continue heating for 20-30min, magnetic adsorption, and then use distilled water and absolute ethanol respectively Repeated washing several times until the washing liquid is neutral, evaporated to dryness, and obtained the black product magnetic Fe 3 o 4 Nanoparticles (MNPs).

[0067] 2) Magnetic Fe 3 o 4 SiO 2 Synthesis of Nanospheres:

[0068] The magnetic Fe of step 1) 3 o 4 Put 1.5g of nanospheres into a 250ml two-neck flask, add 80ml of absolute ethanol, and 20ml of water, stir for 10min under argon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com