Experimental device for hydrogen permeation behaviors of local areas of metal

A local area and experimental device technology, which is applied in the field of measuring instruments, can solve problems such as failure to apply, stress corrosion cracking, etc., and achieve the effects of low test cost, flexible test methods, and high accuracy of test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

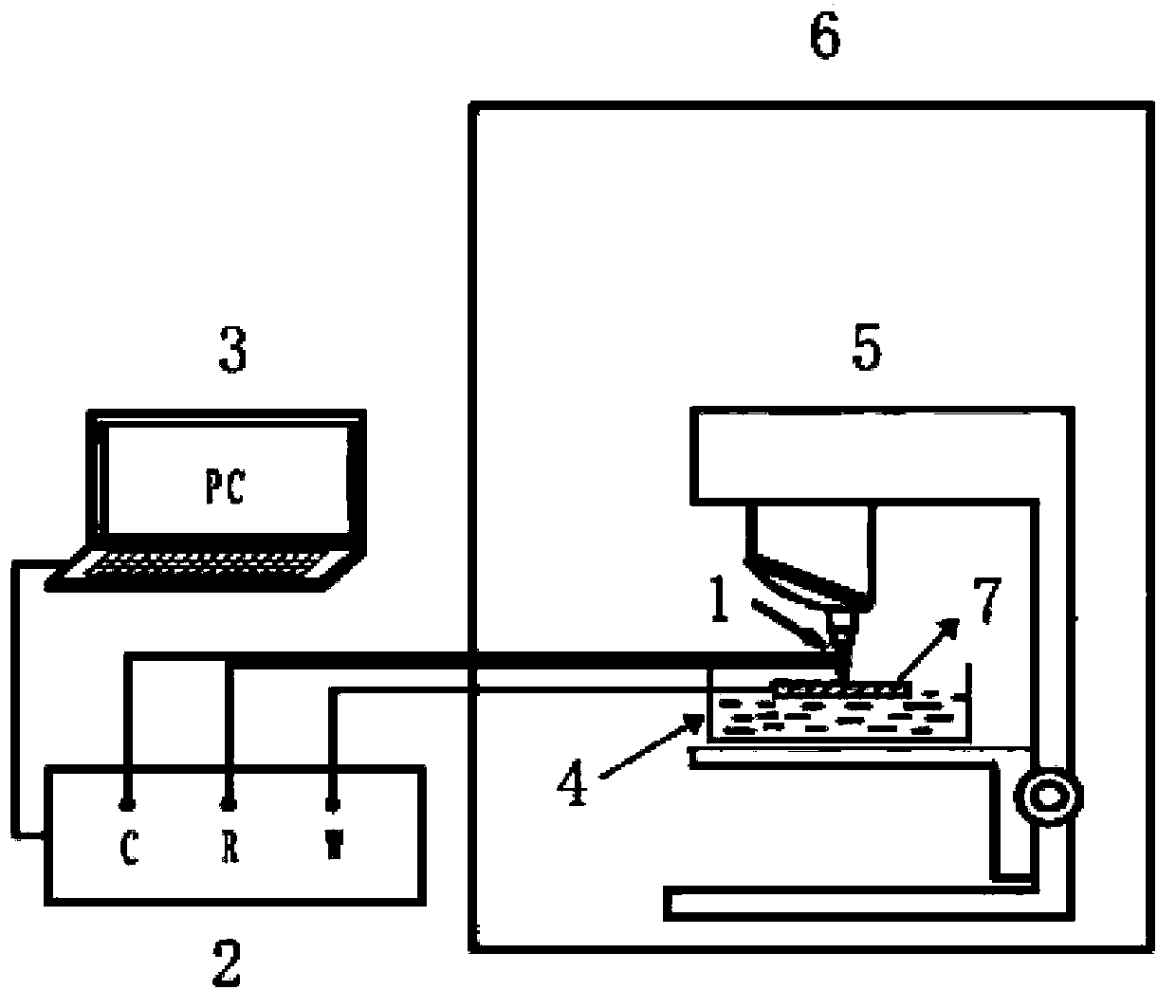

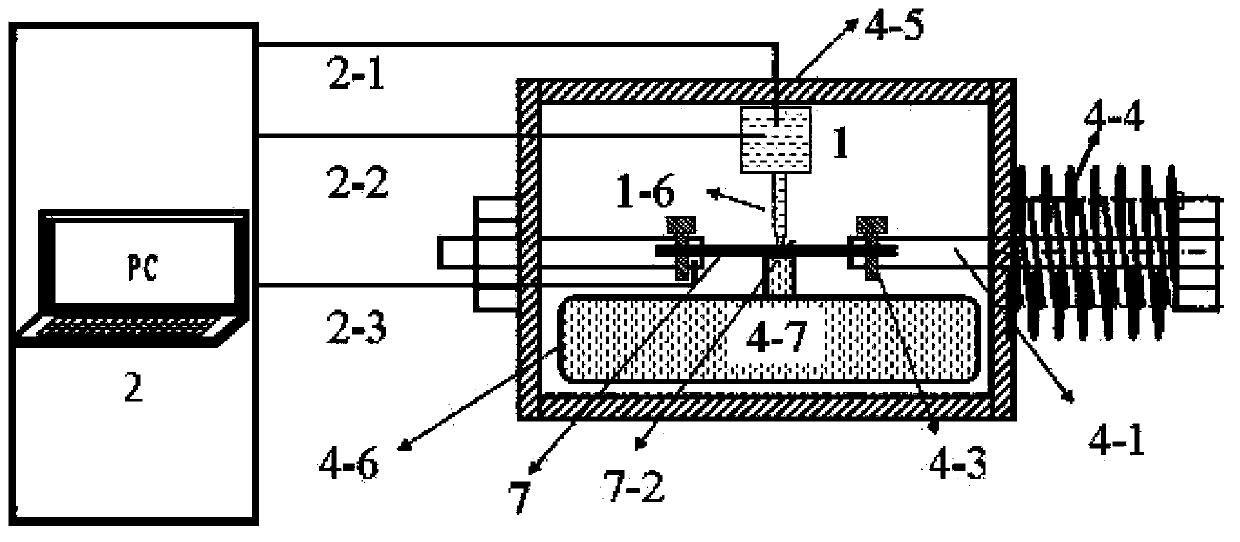

[0031] combine figure 1 , The structure of the first embodiment of the present invention includes a micro-electrolytic cell 1, a corrosive environment simulation tank 4, an object-loading test bench 5, a Faraday electrostatic shielding box 6, and a working sample 7. Wherein the working sample 7 is installed in the corrosive environment simulation tank 4, one end of the micro-electrolytic cell 1 is in contact with the working surface of the working sample 7, and the micro-electrolytic cell 1 and the corrosive environment simulating tank 4 are all fixed on the loading test platform 5, and the loading experiment The table 5 is placed in a Faraday electrostatic shielding box 6 .

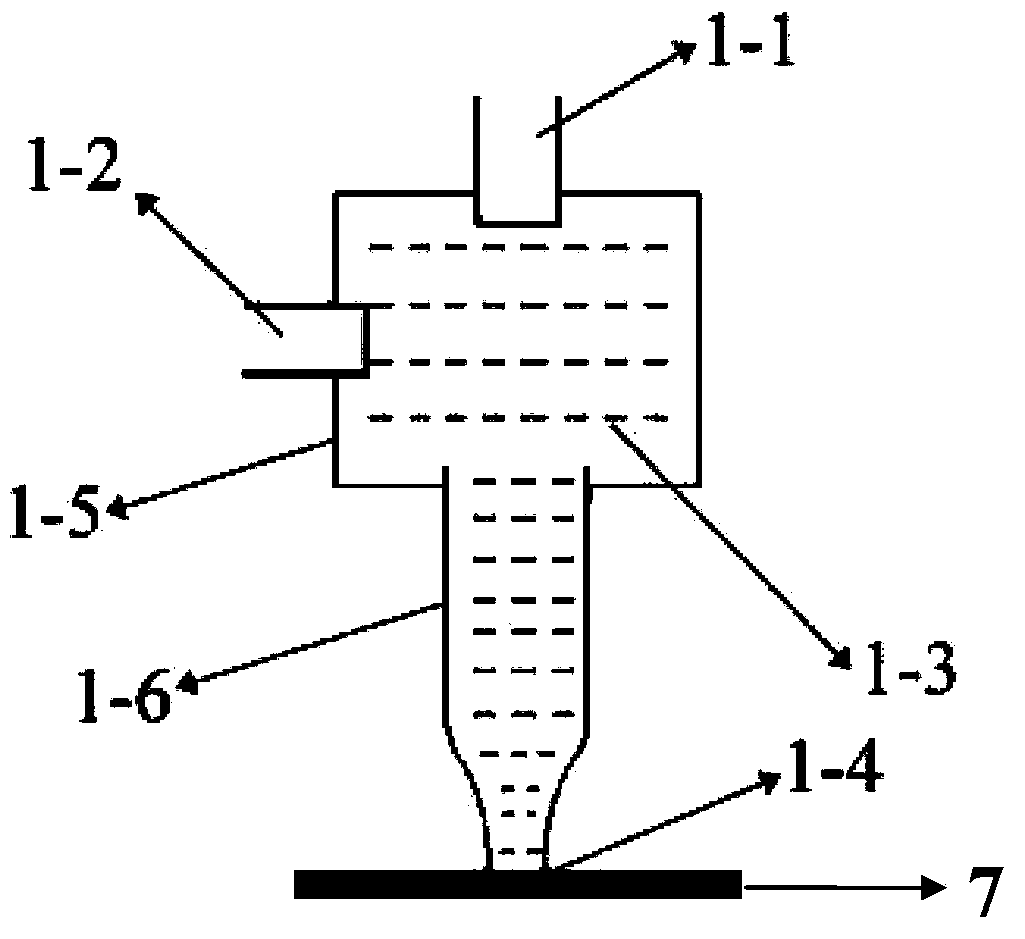

[0032] combine figure 1 and figure 2 , the micro-electrolytic cell test system uses a counter electrode 1-1, an Ag / AgCl reference electrode 1-2 and a working sample 7 to form a three-electrode system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com