Indoor pull-out test apparatus for anchor rod

A technology of pull-out test and anchor rod, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of anchorage system failure, simple structure, and lower pull-out force, and achieve wide application range, reasonable design, Easy to install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

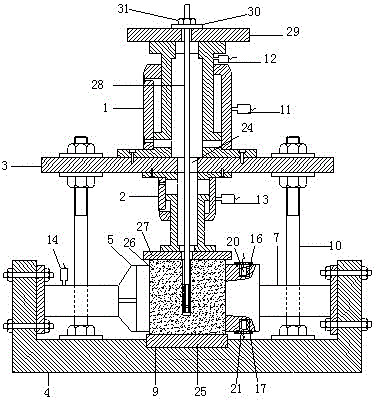

[0014] A bolt indoor pull-out test device of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] see Attachment.

[0016] An indoor pullout test device for anchor rods, the test device is composed of a horizontal loading system, a vertical loading system, an anchor rod pulling system, a box body 4, a support column 10, and a supporting plate 3, and the box body 4 is in an open shape. The horizontal loading system is composed of a first horizontal loading jack 5, a second horizontal loading jack 6, a first horizontal load reaction device 7, and a second horizontal load reaction device 8. The first horizontal loading jack 5 and the second horizontal loading jack 6 They are respectively fixedly arranged on the two inner side walls of the box body 4, the axes of the first horizontal loading jack 5 and the second horizontal loading jack 6 are perpendicular to each other, and the first horizontal load reaction devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com