Method of cryogenic separation for light hydrocarbons on the basis of LNG (liquefied natural gas) cold energy

A technology for cryogenic separation and light hydrocarbons, which is applied in the field of cryogenic separation of light hydrocarbons based on LNG cold energy, and the separation of light hydrocarbon mixtures in refinery, which can solve the problems of large power consumption, save resources and reduce power consumption of compression , the effect of reducing energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, a refinery dry gas separation is taken as an example, as follows:

[0031] The light hydrocarbons of a 12 million tons / year refinery mainly come from atmospheric and vacuum, catalytic cracking, delayed coking, hydrocracking, reforming and other devices. The light hydrocarbons of different components enter the dry gas pipeline network and are purified and dried by compressed alkaline washing Then, 78.23t / h, 15°C, 3.45MPa dry gas is obtained, and its composition (mass fraction) is shown in Table 1 below:

[0032]

[0033] Table 1 Composition of refinery dry gas

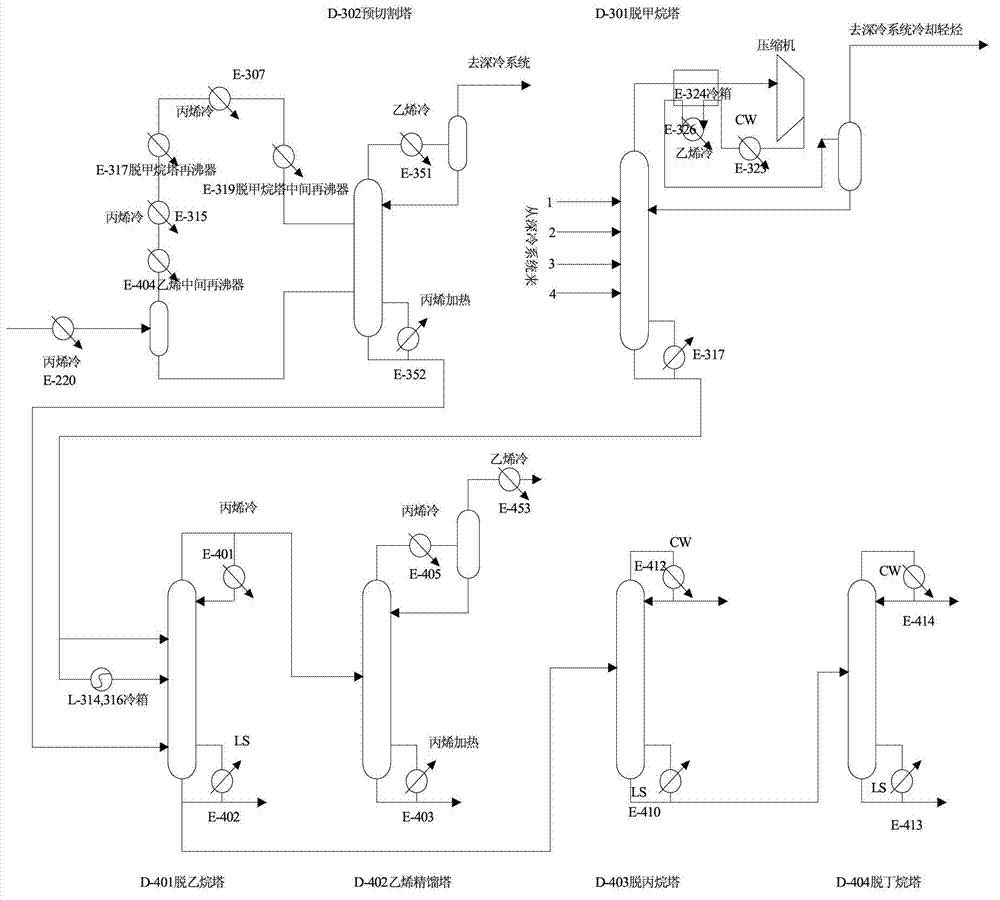

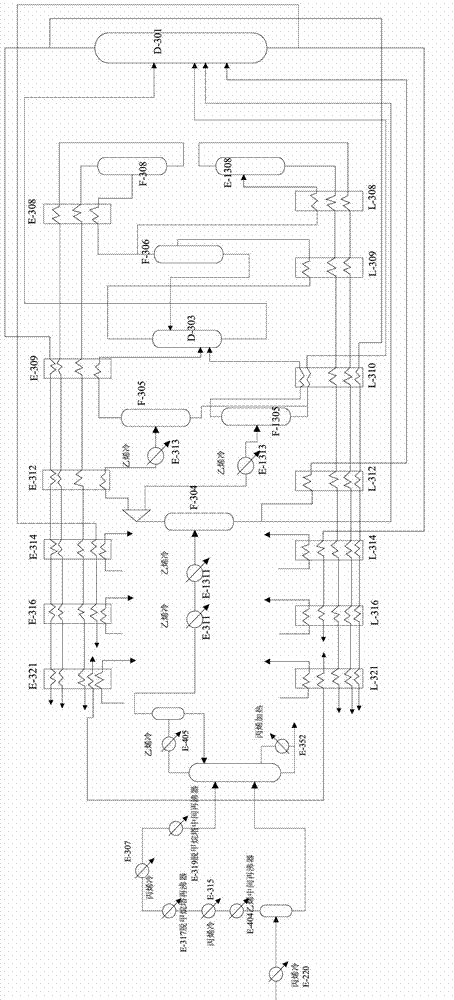

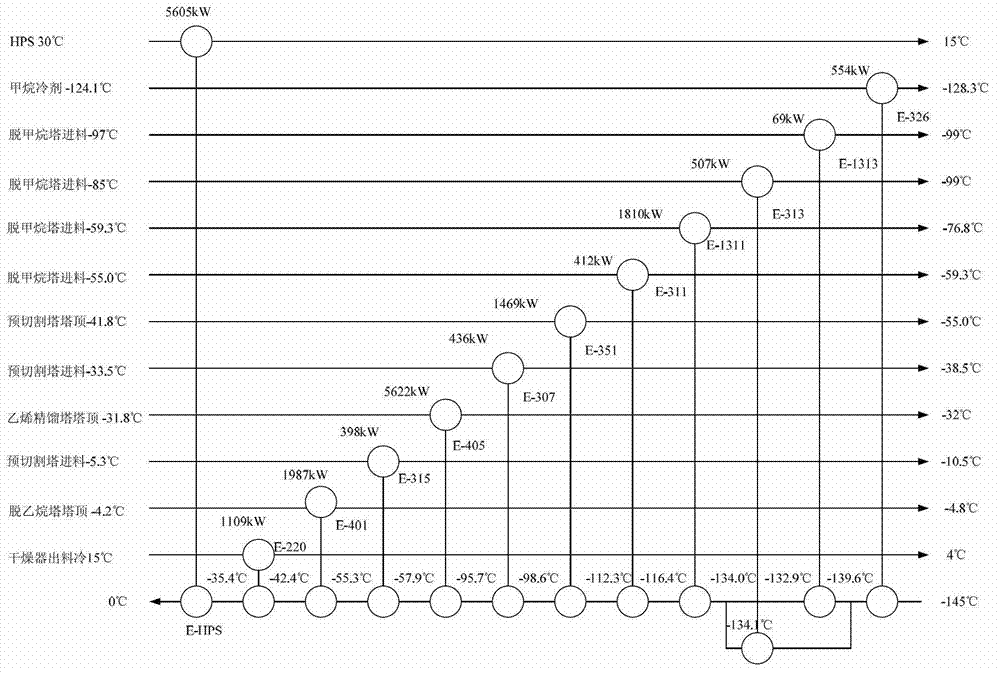

[0034] The cryogenic separation process of refinery dry gas is as follows: figure 1 with figure 2 As shown, the feed gas passes through the pre-cutting tower D-302 to separate light hydrocarbons above ethane from the bottom of the tower and then divides it into two streams into the de-ethanizer D-401. The top of the pre-cutting tower is discharged into the cryogenic system after cryogenic It is div...

Embodiment 2

[0043] This embodiment takes the separation of ethylene cracking gas as an example, as follows:

[0044] Taking the 400,000 t / a ethylene cracking gas separation process as an example, the cracking gas flow rate of the ethylene cracking unit is 97.75t / h. Its composition (mass score) is shown in Table 3:

[0045]

[0046] Table 3 Composition of ethylene cracking gas

[0047] The cryogenic separation process of ethylene cracking gas is as follows: Figure 4 with Figure 5 As shown, the ethylene cracking gas passes through the pre-cutting tower D-302 to separate light hydrocarbons above ethane from the bottom of the tower and then divides it into two streams into the de-ethanizer D-401, and the top discharge of the pre-cutting tower enters the cryogenic system for cryogenic cooling. After being divided into four strands, it enters the demethanizer D-301; the top output of the demethanizer is compressed and then enters the cryogenic system for deep cooling, and the bottom output of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com