Air conditioning system and method for detecting liquid level of air-liquid separator of air conditioning system

A gas-liquid separator and air-conditioning system technology, which is applied in liquid level indicators for physical variable measurement, refrigeration and liquefaction, refrigeration safety arrangements, etc., can solve the problem of compressor over-humidity operation, single function, and affecting system safety and reliability problem, to avoid bias current and ensure safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

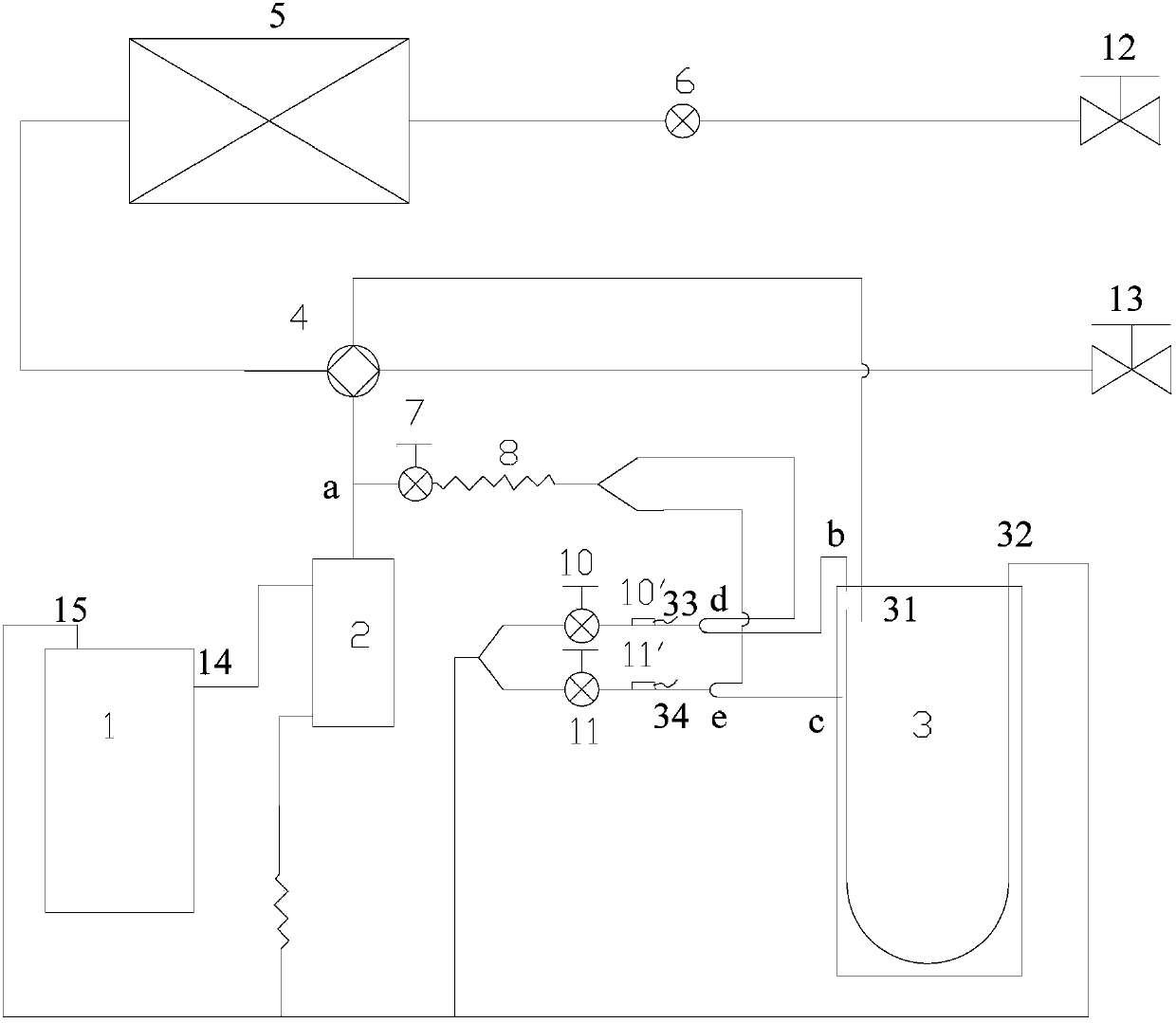

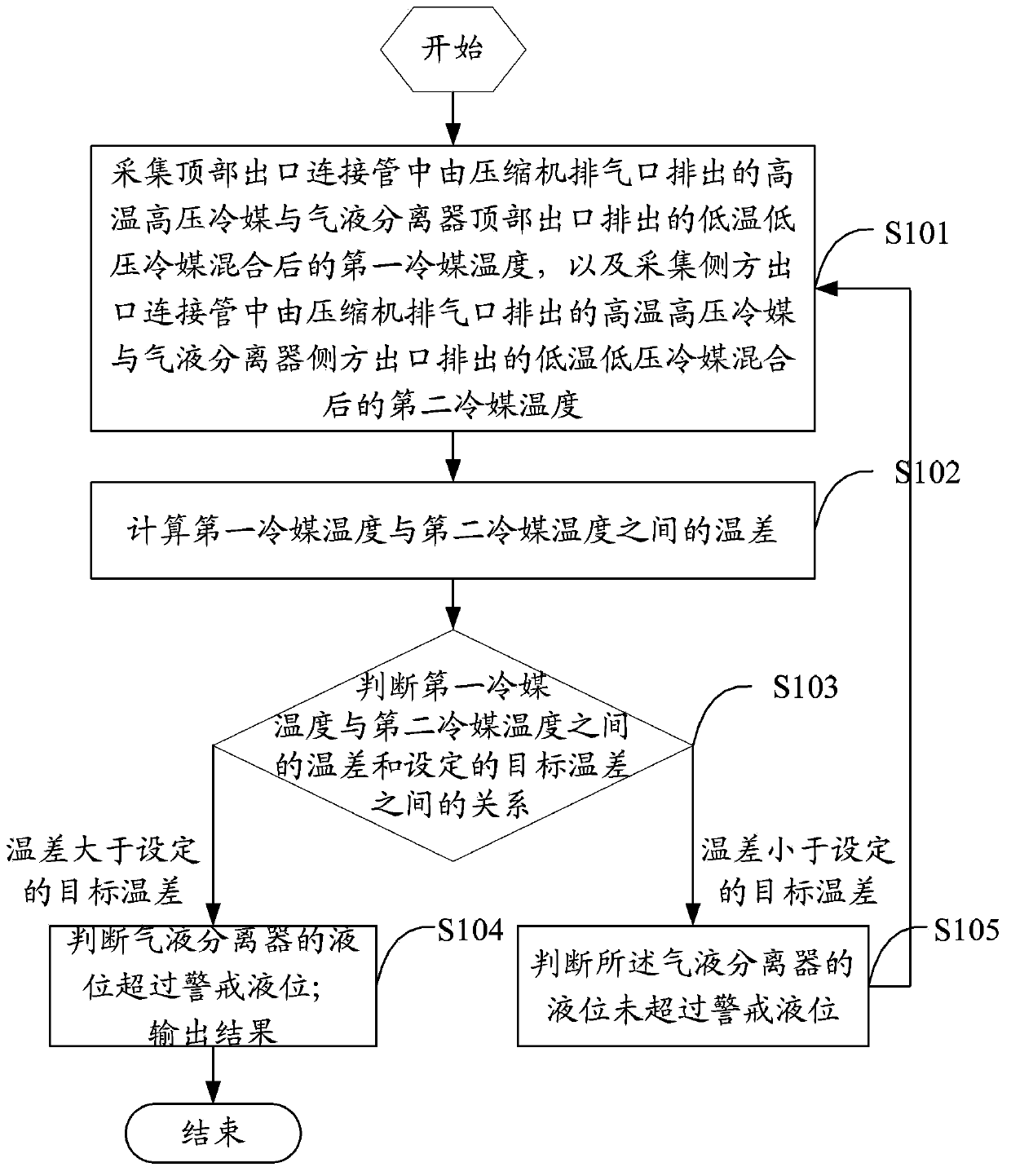

[0026] Such as figure 1 As shown, the preferred embodiment of the present invention proposes an air conditioning system, including: a compressor 1, a four-way valve 4, an outdoor heat exchanger 5, a throttling device 6 and an indoor heat exchanger (not shown in the figure) that are sequentially connected to form a circuit shown), a gas-liquid separator 3 is connected between the compressor 1 and the four-way valve 4, wherein:

[0027] The compressor 1 has an exhaust port 14 and an air return port 15; the four-way valve 4 has an intake end, an exhaust end, an evaporation end and a condensation end; the exhaust port 14 of the compressor 1 is connected to the intake end of the four-way valve 4, The air return port 15 of the compressor 1 is connected to the exhaust end of the four-way valve 4 through the gas-liquid separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com