Vibration absorber based on polyurethane filler

A polyurethane filler and shock absorber technology, which is applied in the field of vibration and noise reduction, can solve the problems of reduced production efficiency, system forming movement interference and damage, and reduced machine life, so as to achieve simple structure, improve production efficiency and machine life , to overcome the effect of interference and destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

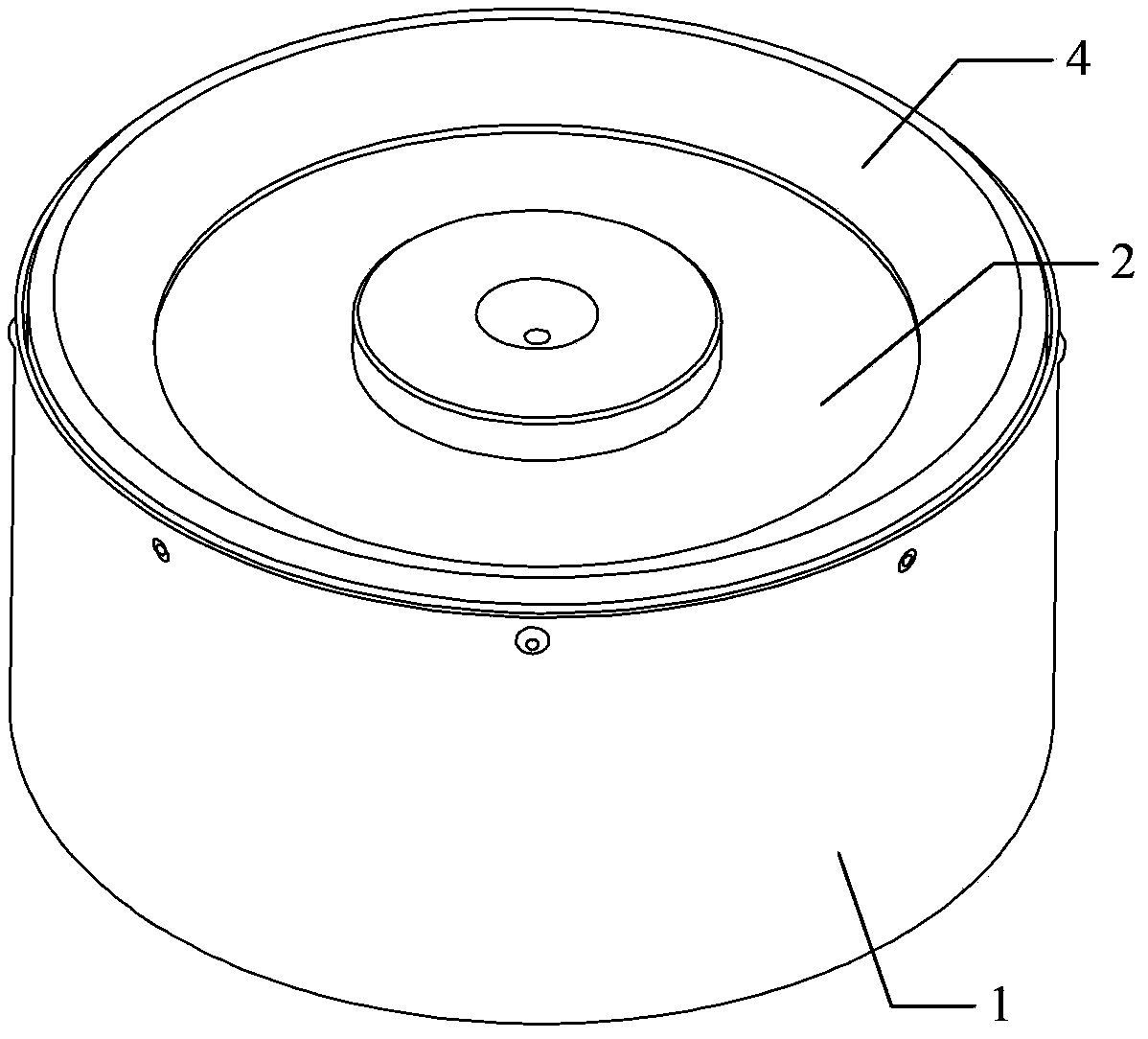

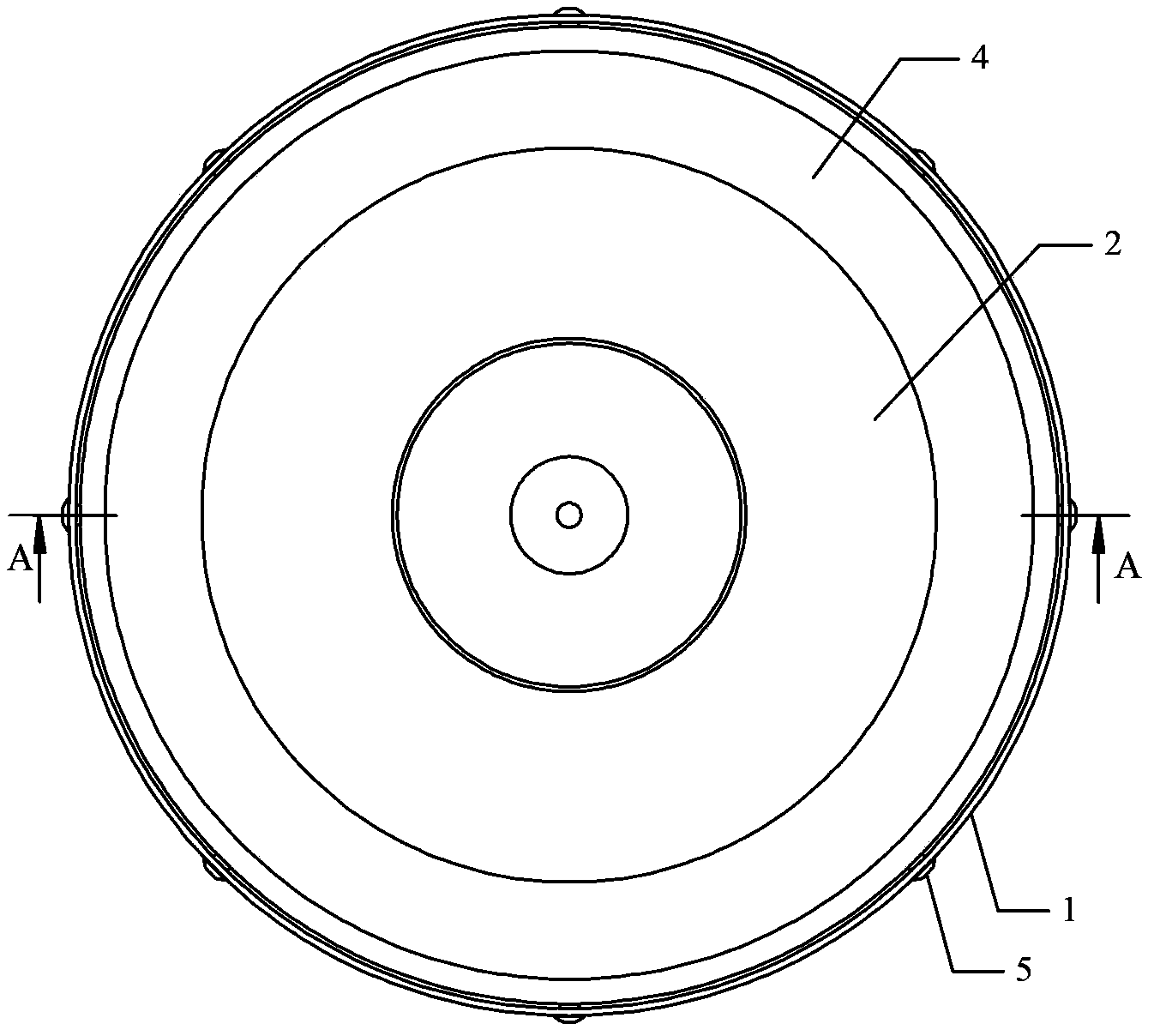

Image

Examples

Embodiment 1

[0051] The shell diameter of the shock absorber based on the polyurethane filler of the present embodiment is 213mm, and the shell height is 105mm, wherein, the mass ratio range of the polyurethane particles and the filler in the elastic particles is 8:2-9:1, different types of shock absorbers The load bearing capacity of the device is different from the yield force. The load range is 1000KG-1350KG, the maximum load is 1550KG, the yield force range is 2.3KN-6.6KN, the linearity after yielding is good, and the stiffness range is 0.53KN / mm- 0.82KN / mm.

[0052] Production Method:

[0053] Put a certain amount of elastic granules into the net bag, tie them up and weigh them without leakage, place them in the shell, and assemble them on the special fixture. The order from top to bottom is fixed ring, backing plate, rubber pad, and elastic granules. and casing.

[0054] Carry out its force and displacement test, determine its yield force, stiffness, and whether the linearity after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com