High-frequency wide-temperature low-loss manganese-zinc ferrite and manufacturing technique thereof

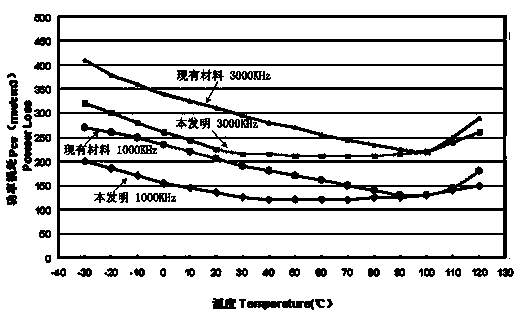

A manganese-zinc ferrite and low-loss technology, which is applied in the field of high-frequency, wide-temperature, low-loss manganese-zinc ferrite and its manufacturing process, can solve the problem of high power loss and achieve the effects of excellent performance, low loss, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Proceed as follows:

[0025] (1) Fe 2 o 3 (52mol%), Mn 3 o 4 (42mol%), ZnO (6mol%) main component and trace component TiO 2 (1000ppm) was added to the sand mill for the first wet grinding and mixing for 30 minutes;

[0026] (2) Step (1) Grind the obtained material through a spray dryer to make granules, and then send it to the rotary kiln for pre-burning at a temperature of 850°C, and pass through the rotary kiln once, and the passing time is generally controlled at 2 to 6 minutes;

[0027] (3) Adding Nb to the material obtained by pre-burning in step (2) 2 o 5 (350ppm) and ZrO 2 (250ppm), carry out the second wet grinding and mixing in a sand mill, and grind to an average particle size of 0.8 to 1.0 microns;

[0028] (4) Add polyvinyl alcohol solution with a concentration of 8wt% to the material obtained by grinding in step (3) according to 10wt% of the absolute dry material, stir for 2 hours, pass through a spray dryer, spray granulate, and the particle s...

Embodiment 2

[0032] Under the same situation as that of Example 1, the raw materials used and the consumption amount are changed to: in step 1), the main component is Fe 2 o 3 (53mol%), Mn 3 o 4 (42mol%), ZnO (5mol%) composition, trace composition Ni 2 o 3 (2000ppm), incorporated V in step 3) 2 o 5 (450ppm) and Ta 2 o 5 (360ppm).

Embodiment 3

[0034] Under the same situation as that of Example 1, the raw materials used and the consumption amount are changed to: in step 1), the main component is Fe 2 o 3 (53mol%), Mn 3 o 4 (42mol%), ZnO (5mol%) composition, trace component Co 3 o 4 (4500ppm), incorporated V in step 3) 2 o 5 (580ppm) and Nb 2 o 5 (300ppm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com