A three-dimensional printer with synchronous wire feeding

A technology of a three-dimensional printer and a printing mechanism, which is applied in the field of three-dimensional printers, and can solve problems such as slipping of the wire jamming wheel, affecting printing accuracy and quality, and uneven thickness of thermal fuses, so as to reduce the possibility of slipping and improve printing reliability , Increase the effect of wire feeding thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

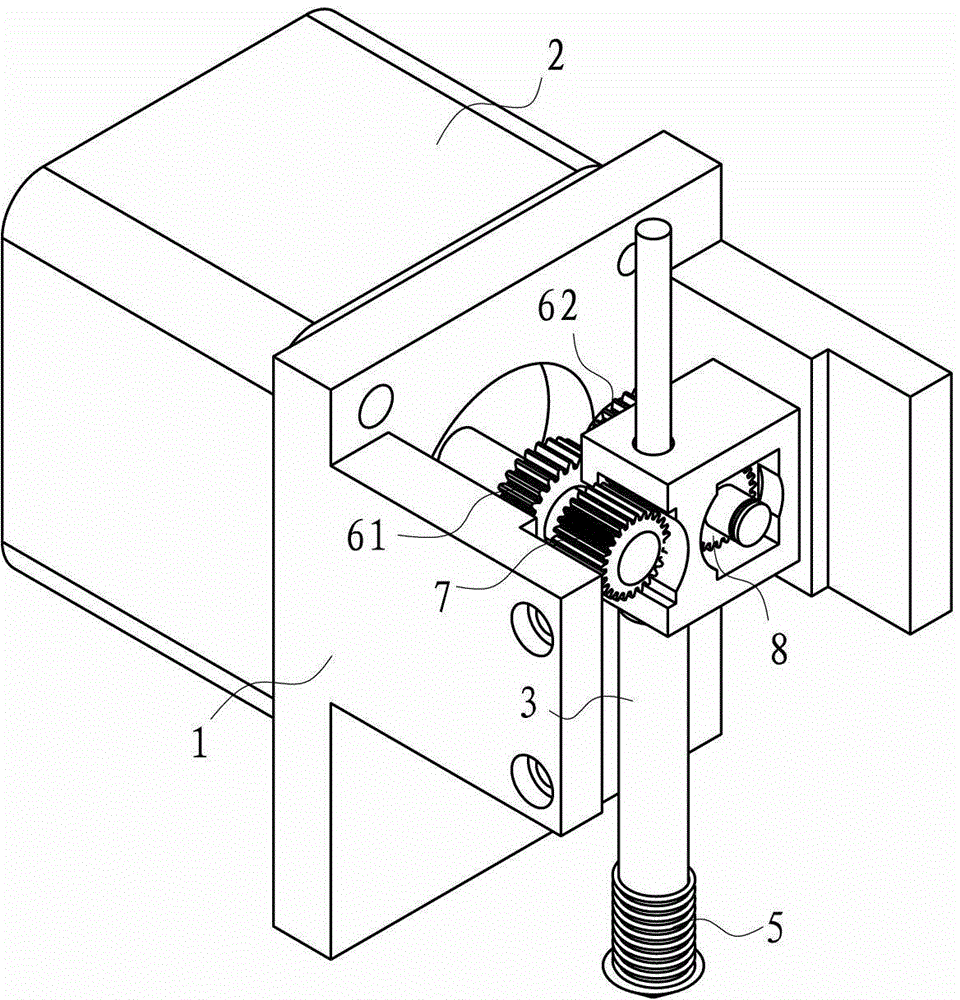

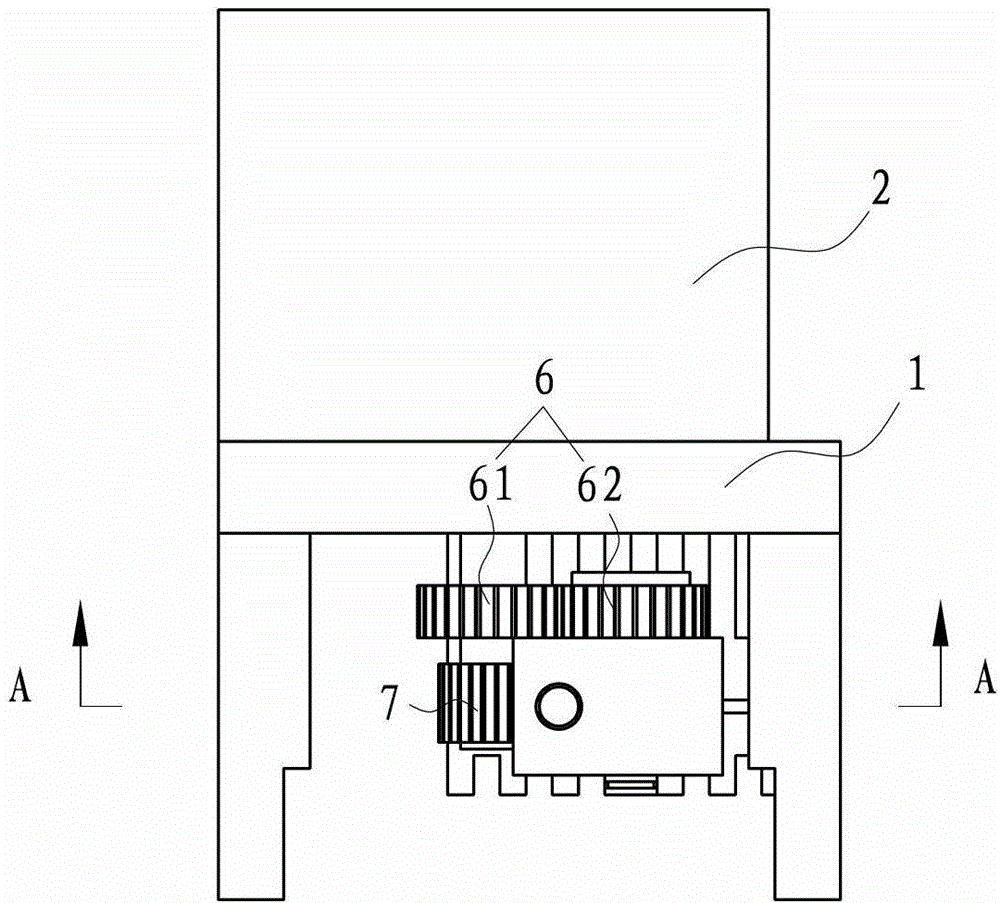

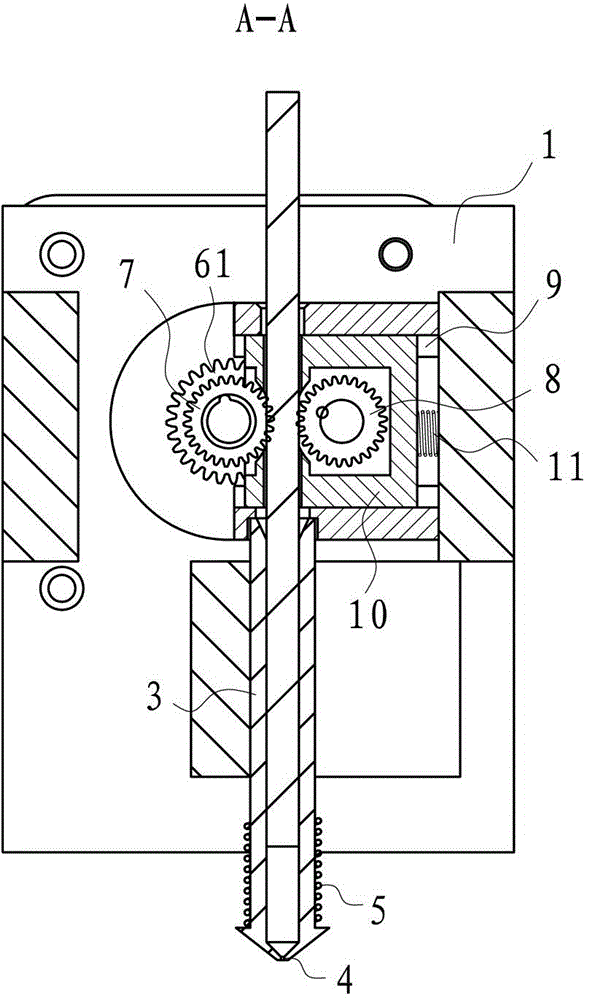

[0017] Embodiment one: see attached Figure 1-4 A three-dimensional printer with synchronous wire feeding is shown, which includes a frame (not shown in the figure), a printing mechanism arranged on the frame, and the printing mechanism includes a mounting seat (1) arranged on the frame, a 1, the servo motor 2 on the 1, the threading wheel group driven by the servo motor 2, the guide tube 3 for introducing the thermal fuse arranged below the threading wheel set, the lower end of the guide tube 3 is provided with a spinning hole 4, and the guide tube 3 is provided with a spinning hole 4. The inlet end of the material pipe 3 is arranged directly below the wire clamping wheel group, and the bottom of the feed pipe 3 is provided with a heating device 5, and the wire clamping wheel group includes a first wire clamping wheel 7 and a second wire clamping wheel 8, and the wire clamping wheel group It also includes a synchronous transmission 6 driven by a servo motor. The synchronous...

Embodiment 2

[0020] Embodiment two: its content is basically the same as embodiment one, and the difference is that the synchronous transmission device 6 includes the driving wheel 61 driven by the servo motor, the combination of the gear set or the gear and the pulley driven by the driving wheel 61, the above-mentioned through gear The driven wheel 62 driven by the set or combination of gears and pulleys.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com