Inverted taper spline spur gear shaper cutter and its design method

A technology of spur gears and inverted cones, which is applied to gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc., can solve the problems of double-linked gears that are labor-intensive and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1 A reverse taper spline spur gear shaper cutter

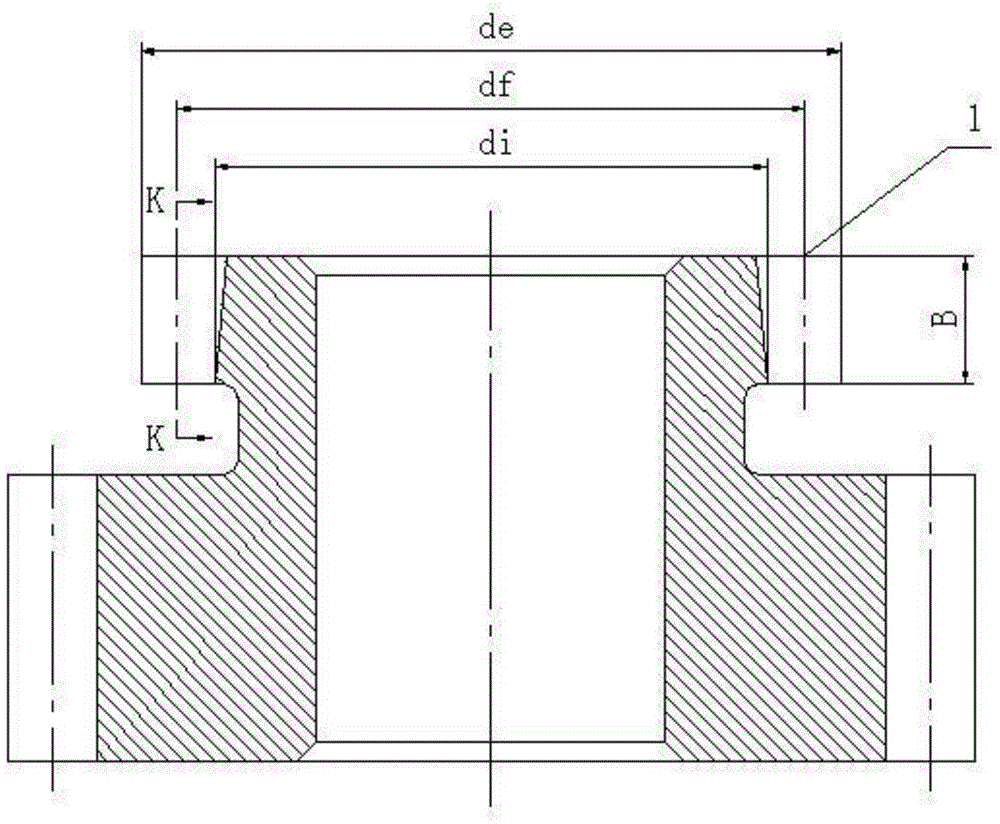

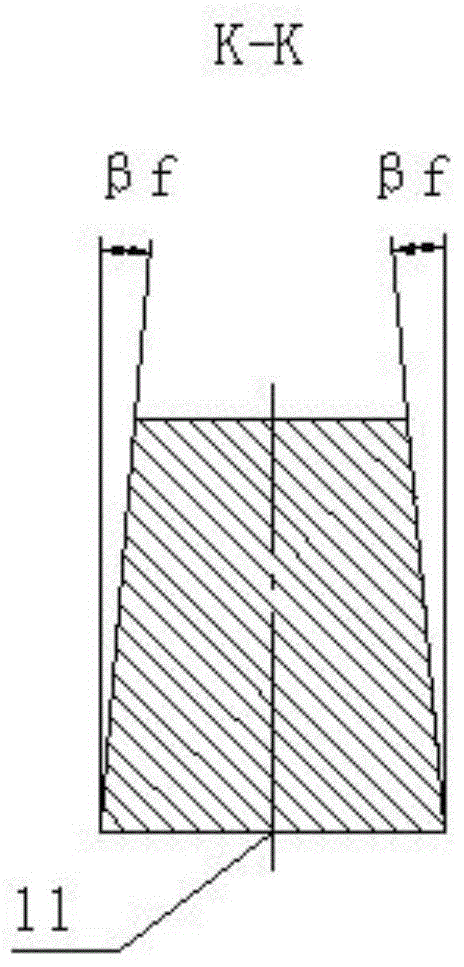

[0069] Take the processing of a spur gear with inverted taper splines as an example with the following parameters: number of teeth Z=39, modulus m=1.8, index circle pressure angle α f =20°, graduated circle side relief angle β f =4°, top circle diameter d e =71.45, root circle diameter d i =67, the number of span teeth K=5, the length of the common normal line W K =24.88.

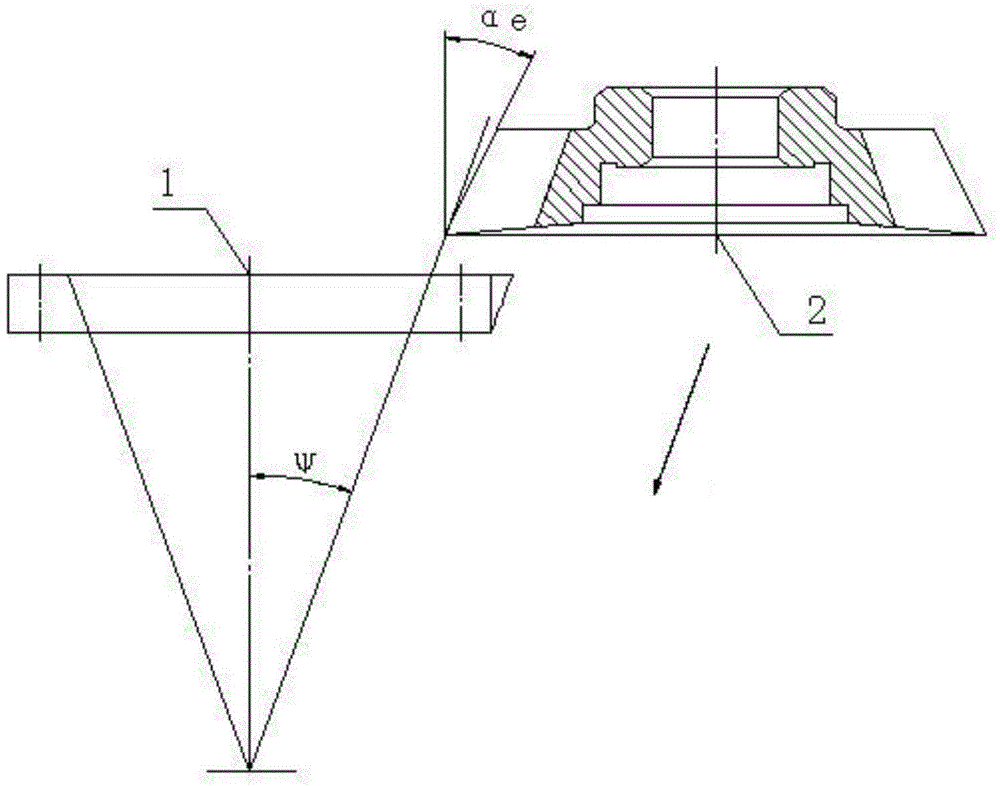

[0070] The basic parameter of the reverse taper spline spur gear shaper cutter described in this embodiment is the number of teeth Z o =56, rake angle γ=5°, addendum relief angle α e =6°, graduation circle diameter d fo = Z o m=100.8, arc tooth thickness S fo =2.696, when ψ satisfies the formula When , the basic parameter of the gear shaper cutter is the indexing circle pressure angle α fo , satisfying the following formula:

[0071]

[0072] According to the basic parameters of the above-mentioned reverse taper spline spur ...

Embodiment 2

[0074] Embodiment 2 A Design Method of Inverted Taper Spline Spur Gear Shaping Cutter

[0075] The present invention provides a design method of a reverse taper spline spur gear shaper cutter 2. The main parameters of the large end face 11 of the reverse taper spline spur gear 1 include the modulus m and the index circle pressure angle α f , Graduated circle side relief angle β f , top circle diameter d e , Pitch circle diameter d f , root circle diameter d i and arc tooth thickness S f , the design method includes the following steps:

[0076] S1) Calculate the insertion installation angle ψ according to the basic parameters of the reverse taper spline spur gear 1 and the gear shaper cutter 2, such as Figure 1-3 As shown, it is known that:

[0077] Involute function of spur gear with reverse taper spline: invα f =tanα f -α f

[0078] Inverted taper spline spur gear pitch circle diameter: d f =Zm

[0079] Inverted taper spline spur gear base circle diameter: d b ...

Embodiment 3

[0127] Example 3 proves the correctness of designing gear shaper cutters with V-V plane equivalent parameters

[0128] Then, the V-V plane tooth profile calculated by the parameters of the large end face of the inverted taper spline spur gear is compared with the tooth profile calculated by the equivalent parameters of the V-V plane to see if they coincide, that is to prove whether the gear shaper cutter is designed with the equivalent parameters of the V-V plane. Coordinate calculation formula to prove:

[0129] ①Calculation of V-V plane tooth profile by using the large end face parameters of reverse taper spline spur gear

[0130] Calculate the coordinates of the V-V plane tooth profile in space according to the parameters of the large end face of the spur gear with inverted taper spline, as shown in Figure 6 shown, where:

[0131] d a = d e +[2B-(d e -di )tanψ]sinψcosψ

[0132] (Number of points: N=1, 2, 3...n)

[0133] d n = d a -NΔd

[0134] Y n =(d n -d i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com