Blowing draining device for filtering machine

A blowing device, filter technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of poor effect and unsatisfactory filtration effect, achieve low cost, improve solid-liquid separation effect, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

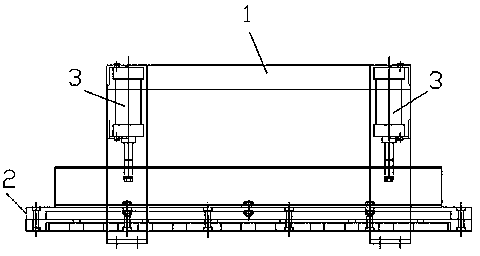

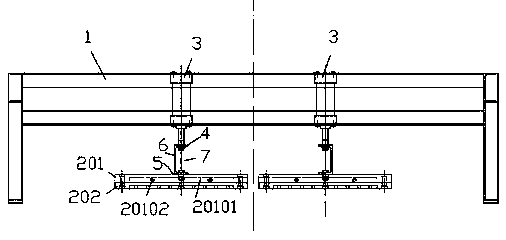

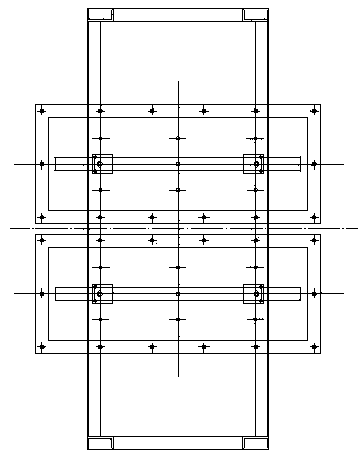

[0034] Embodiment 1, see attached figure 1 , 2 , 3, 4, the air-blowing and drying device used for the filter, including a support 1, an air-blowing device 2 and a lifting mechanism 3 for driving the air-blowing device 2 to lift, and the air-blowing device arranged on the support 1 is based on actual conditions. Determination of demand, in this embodiment, there are two, each air blowing device 2 is brought up and down by a lifting mechanism 3, and the lifting structure 3 is a cylinder or an oil cylinder, in this embodiment, it is two cylinders, and the blowing device 2 The device 2 includes an upper grid plate 201, a lower grid plate 202 fixedly connected with the upper grid plate 201 and a filter cloth 203 fixed on the lower surface of the lower grid plate 202, the upper grid plate 201 A compressed air chamber 20101 and a compressed air inlet 20102 communicating with the compressed air chamber 20101 are provided; the lower surface of the lower grid plate 202 is provided with...

Embodiment 2

[0036] Embodiment 2, see attached Figure 5The lifting mechanism 3 is connected with the upper grid plate 201 through a connecting piece; the connecting piece includes a guide sleeve 8 connected with the lifting mechanism 3, and the guiding sleeve 8 is provided with a cavity, and the cavity The bottom is provided with an opening, the guide shaft 9 is plugged into the cavity, and its lower end protrudes from the opening to connect with the lower grid plate, the guide shaft 9 can slide axially in the cavity, and at the same time, the guide shaft 9 A spring 10 located in the cavity is arranged between the guide sleeve 8, and the spring is a cylindrical helical compression spring. In this way, the pressure of the cylinder on the lower grid plate is elastic, so that when the solid-liquid is separated, The lower grid plate can repeatedly move slightly up and down to form vibrations and improve the solid-liquid separation effect. The maximum compressible amount of the spring 10 is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com