Aromatic tobacco ethyl alcohol and propylene glycol mixed solution extract and preparation method and application of aromatic tobacco ethyl alcohol and propylene glycol mixed solution extract

A technology of mixed solution and refined propylene glycol, which is applied in the field of oriental tobacco, can solve the problems of over-prominent and irritating aroma of oriental tobacco, and unharmonious aroma of oriental tobacco extract. Conducive to the effect of industrialized mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

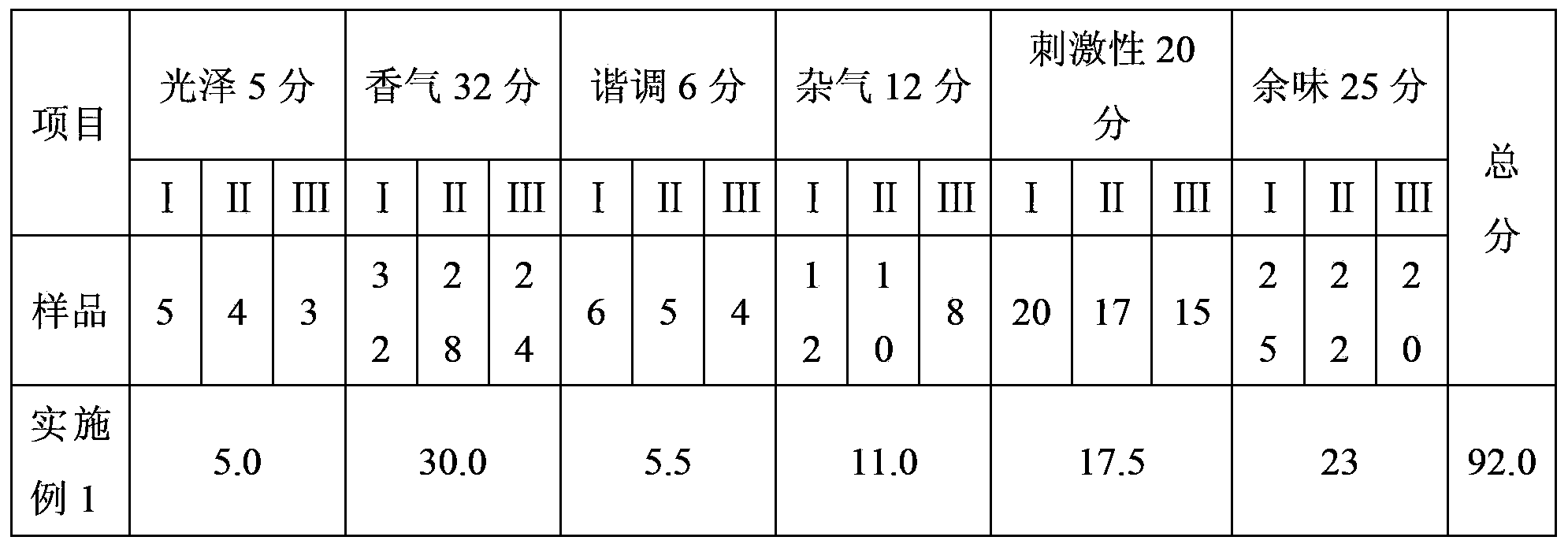

Examples

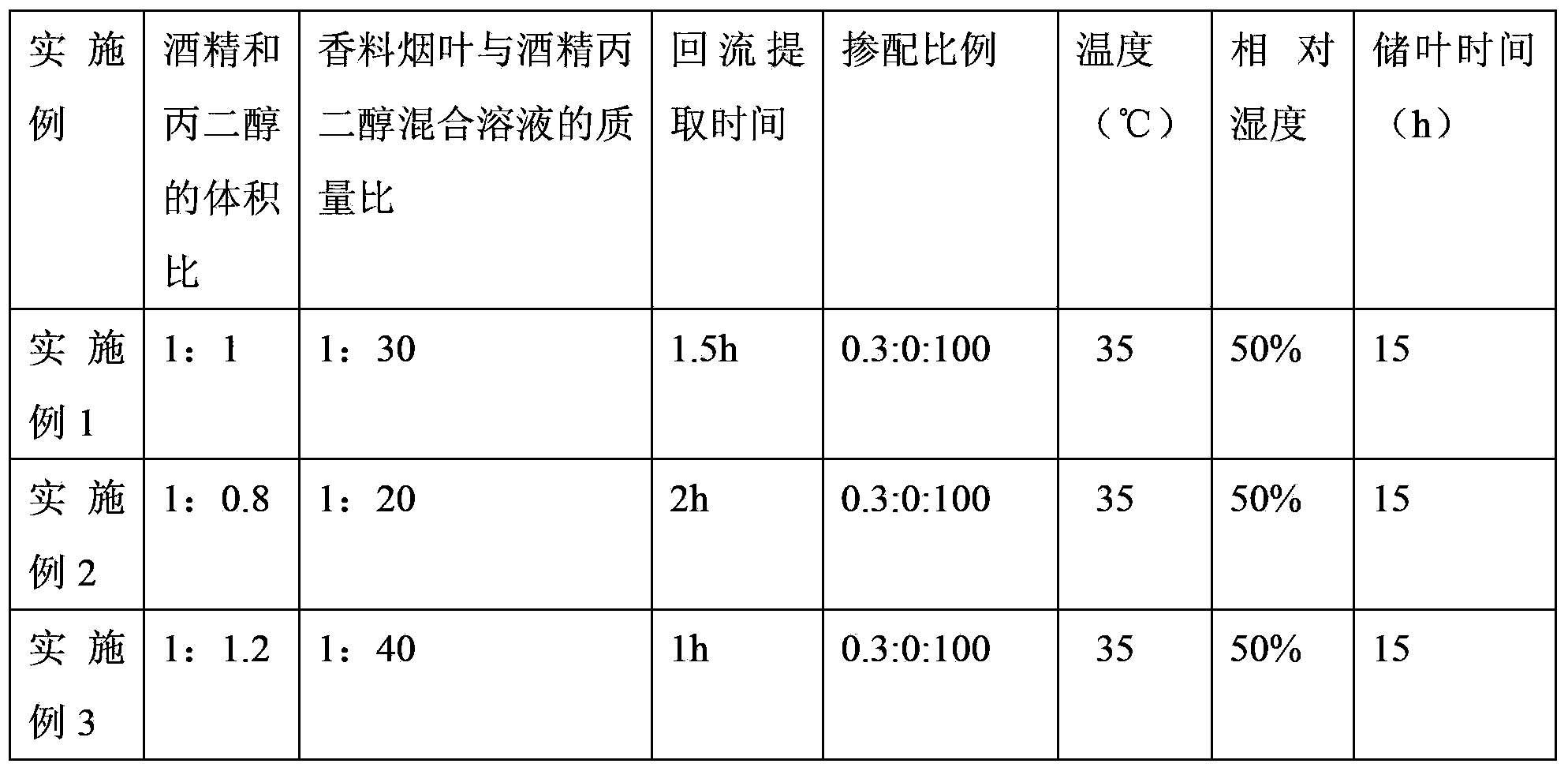

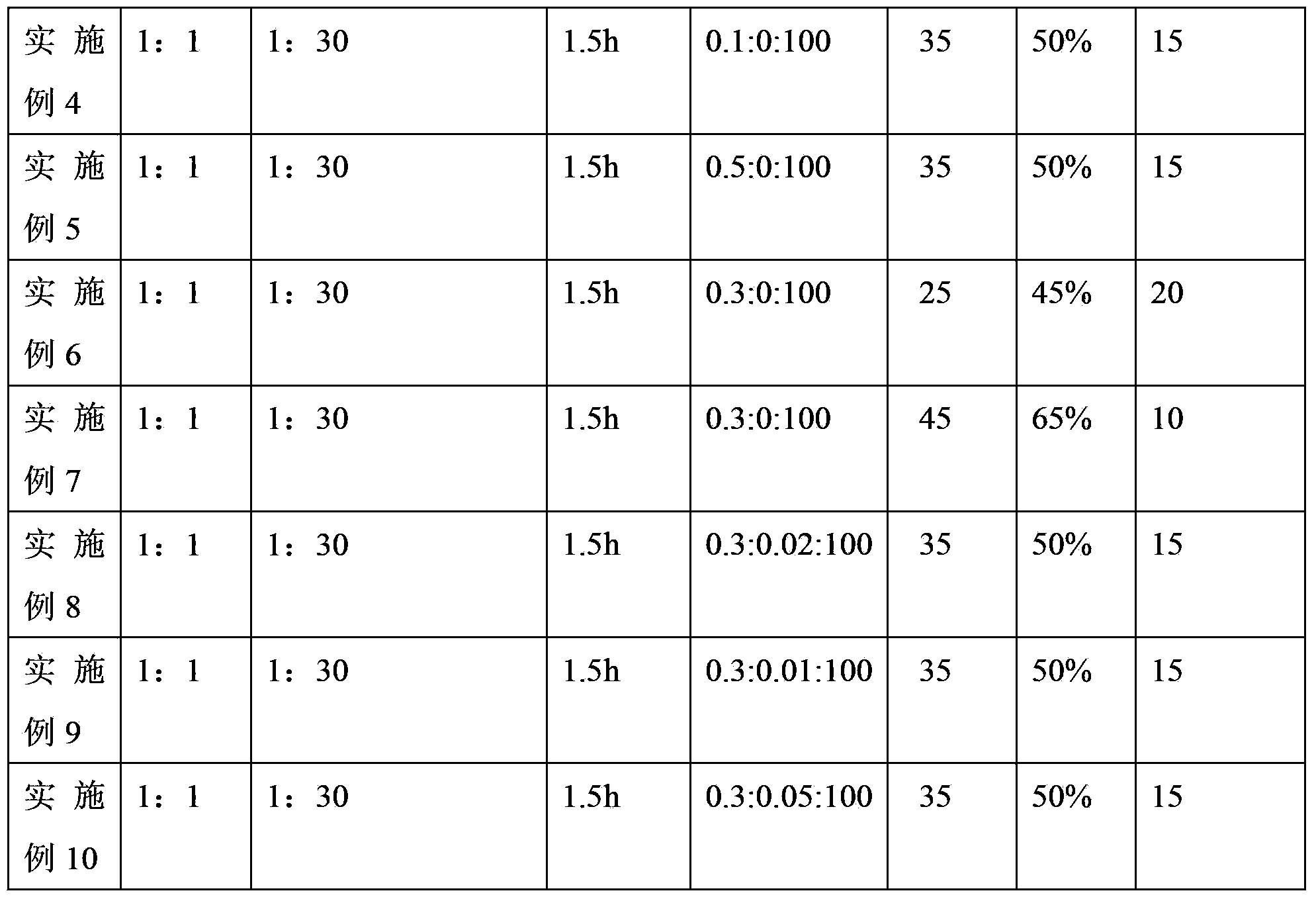

Embodiment 1~10

[0036] One, the preparation of oriental tobacco alcohol propylene glycol mixed solution extract:

[0037] Put the threshed and re-roasted oriental tobacco leaves (Xinchang County, Zhejiang Province, SAMSUN variety, the upper first grade) and the alcohol-propylene glycol mixed solution into the extraction tank to mix, and reflux extraction for 0.5h to 3h to obtain the oriental tobacco alcohol-propylene glycol mixed solution for extraction material, accompanied by intermittent stirring during the reflux extraction process;

[0038] The alcohol-propylene glycol mixed solution is formed by mixing alcohol and propylene glycol with a volume ratio of 1:0.5~2, and the propylene glycol is 1,3-propanediol;

[0039] The mass ratio of the threshed and redried oriental tobacco leaves to the alcohol-propylene glycol mixed solution is 1:10-50.

[0040] Second, the preparation of cigarettes:

[0041] According to the product requirements, the formula design of the leaf group is carried out (l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com