Test board of micro-tillage machine

A test bench and micro-tiller technology, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problem of inability to accurately determine whether there is abnormal noise in the gear meshing in the gearbox, test interference of the micro-tiller, and engine noise. Large and other problems, to achieve the effect of preventing up and down vibration, reducing work vibration, and reducing noise interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

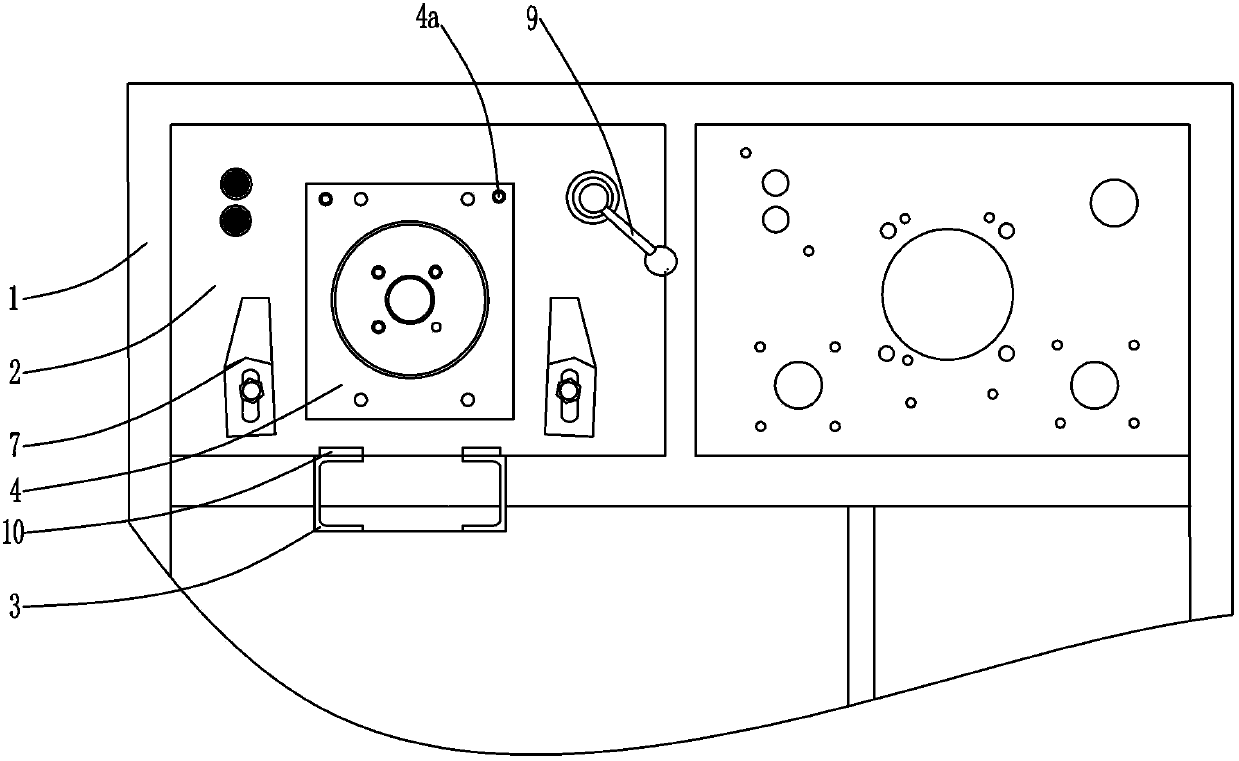

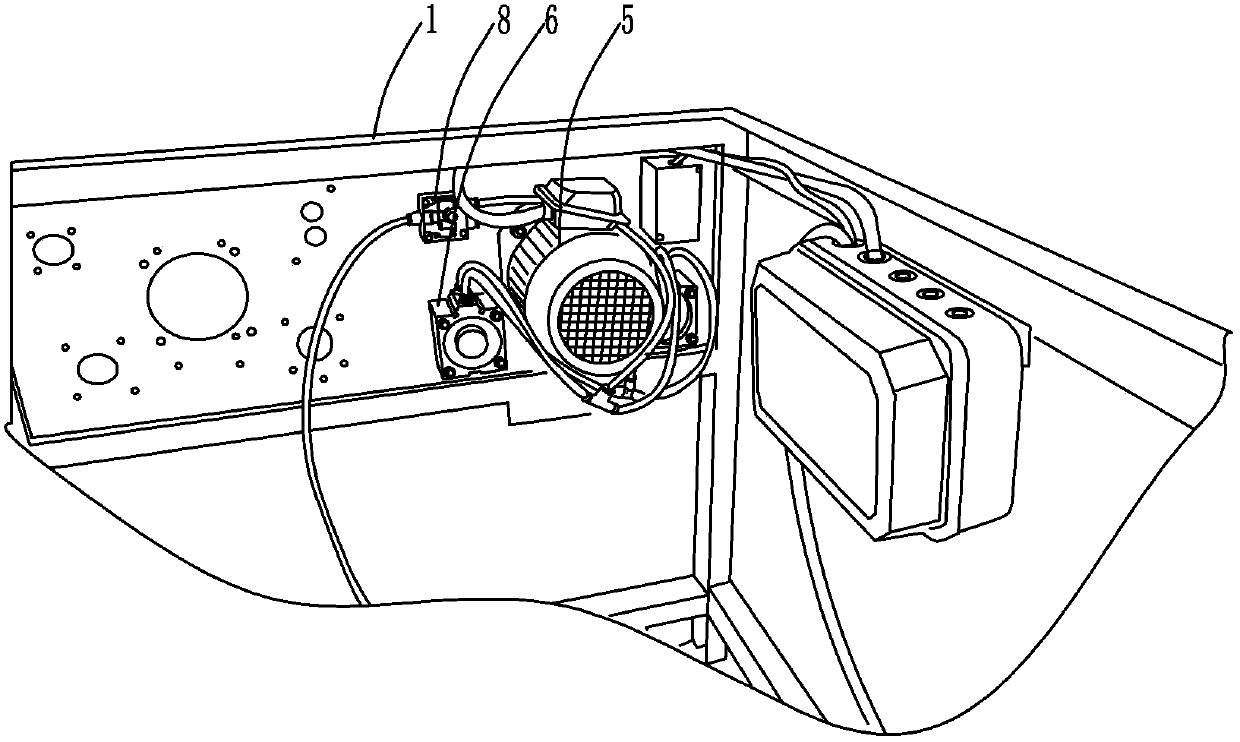

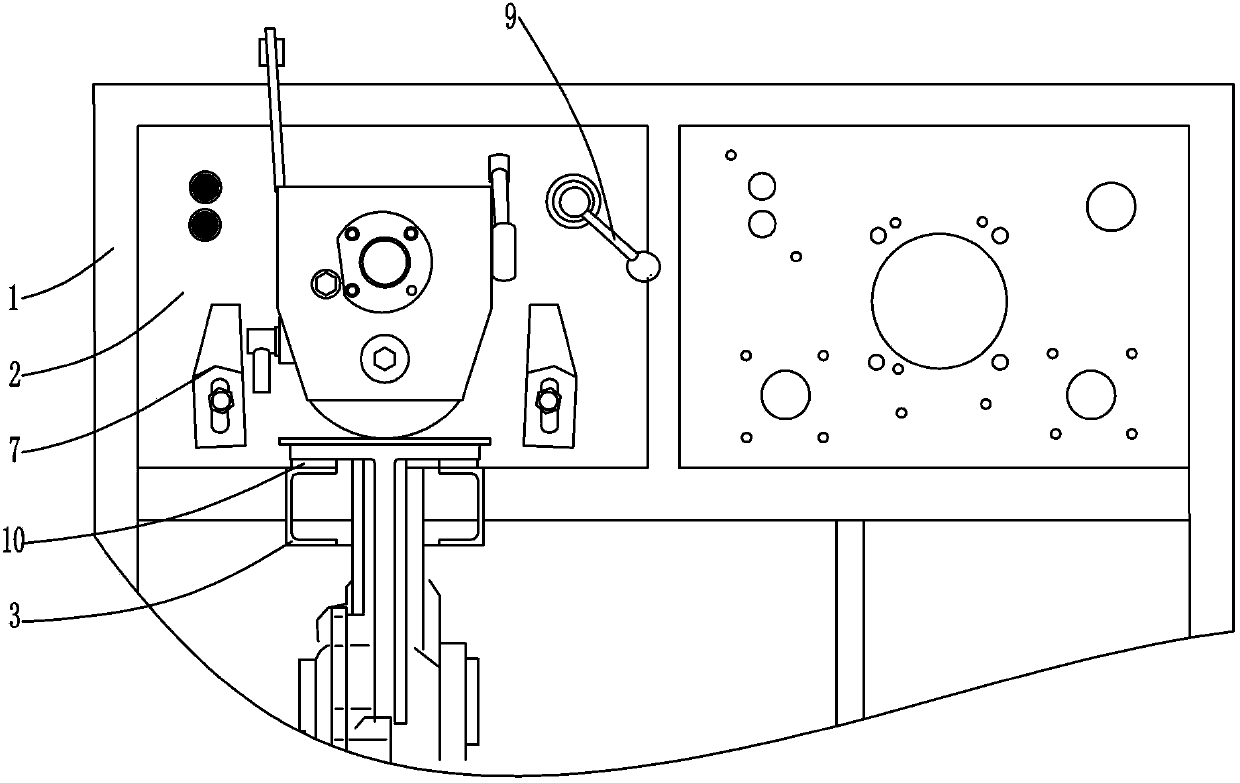

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0025] Such as Figure 1-Figure 4 As shown, the present invention is made up of stand 1, mounting plate 2, support block 3, flange plate 4, motor 5, cylinder 6, briquetting block 7, three-way valve 8, rotating handle 9, antivibration block 10 etc. Described platform 1 is square frame shape, and the upper part of platform 1 front and back sides is fixed with crossbeam, is longitudinally fixed with stiffener between the middle part of crossbeam and the middle part of top beam of platform 1 on the side, and between crossbeam and corresponding top There are two installation frames on the left and right formed between the beams. A mounting plate 2 is provided in each mounting frame, and the four sides of the mounting plate 2 are welded and fixed to the corresponding frame edges of the mounting frame. The lower part of the front of the mounting plate 2 protrudes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com