Wind power generation speed reducer

A technology of reducer and locking mechanism, applied in mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of oil contamination of the service life, large deceleration, and easy vibration of the reducer for wind power generation. The effect of reducing frequent replacement of filter elements, improving clamping effect and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

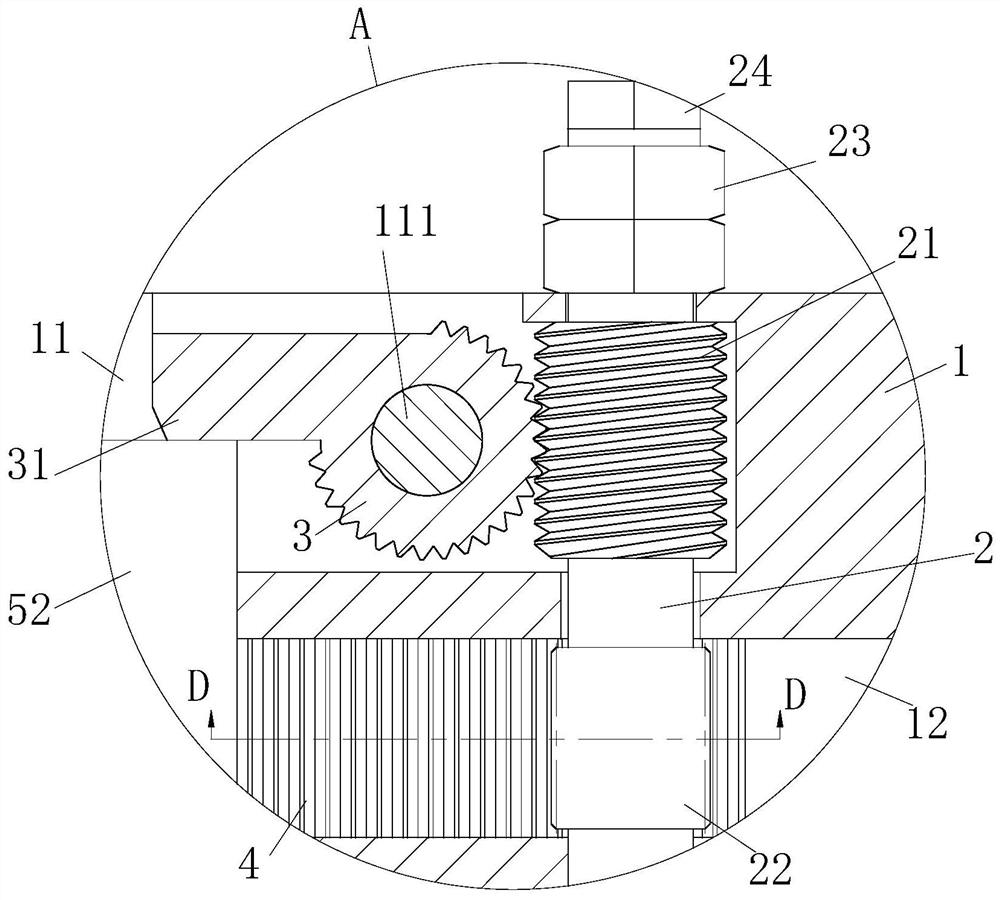

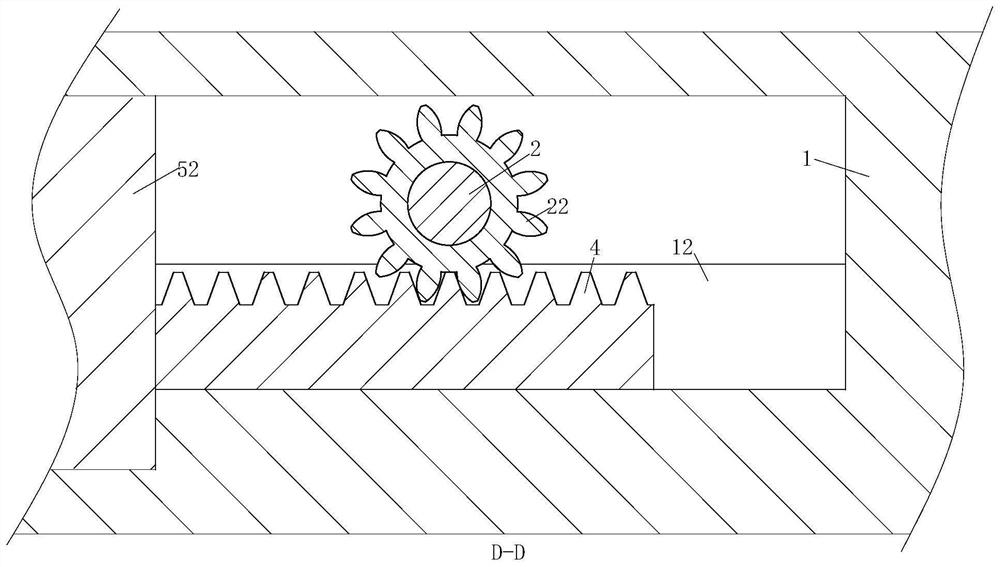

[0029] refer to Figure 1-5 , a reducer for wind power generation, comprising a mounting platform 1, a reducer body 5 and a base 52 fixedly connected to the reducer body 5, the mounting platform 1 is provided with a placement slot 11, and the base 52 is locked by a lock The tightening mechanism is fixed in the placement groove 11. The locking mechanism includes a torsion bar 2, which is rotatably connected with the mounting table 1. The torsion bar 2 is provided with a worm 21 and a gear 22 sequentially from top to bottom. A worm wheel 3 meshed with the worm 21 is rotatably connected in the placement groove 11, and a locking block 31 is fixedly connected to the worm wheel 3, and the locking block 31 fits with the top wall of the base 52, and the placement groove 11 A chute 12 is arranged inside, and a rack 4 is slidably connected to the chute 12, and the rack 4 is meshed with the gear 22;

[0030] One end of the reducer body 5 is rotatably connected with a drive shaft 51, and...

Embodiment approach

[0032] As a specific embodiment of the present invention, a positioning shaft 111 is fixedly connected in the placement slot 11 , and the worm wheel 3 is rotatably connected to the positioning shaft 111 .

[0033] As a specific embodiment of the present invention, the top of the torsion bar 2 is provided with a rectangular locking head 24. In the present invention, the rectangular locking head 24 on the top of the torsion bar 2 can facilitate the clamping and exerting force of the wrench, and facilitate the installation. sex.

[0034] As a specific embodiment of the present invention, lock nuts 23 are threadedly connected to the torsion bar 2, and the number of the lock nuts 23 is specifically two groups. The present invention uses double nuts 23 for locking to prevent the torsion bar from 2 Reversed to improve the locking reliability of the locking mechanism to the base 52.

[0035] As a specific embodiment of the present invention, the filter module 6 includes a filter cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com