Super-sized hanging and stable structure in the inner space of the ceiling

An Inner Space, Oversized Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

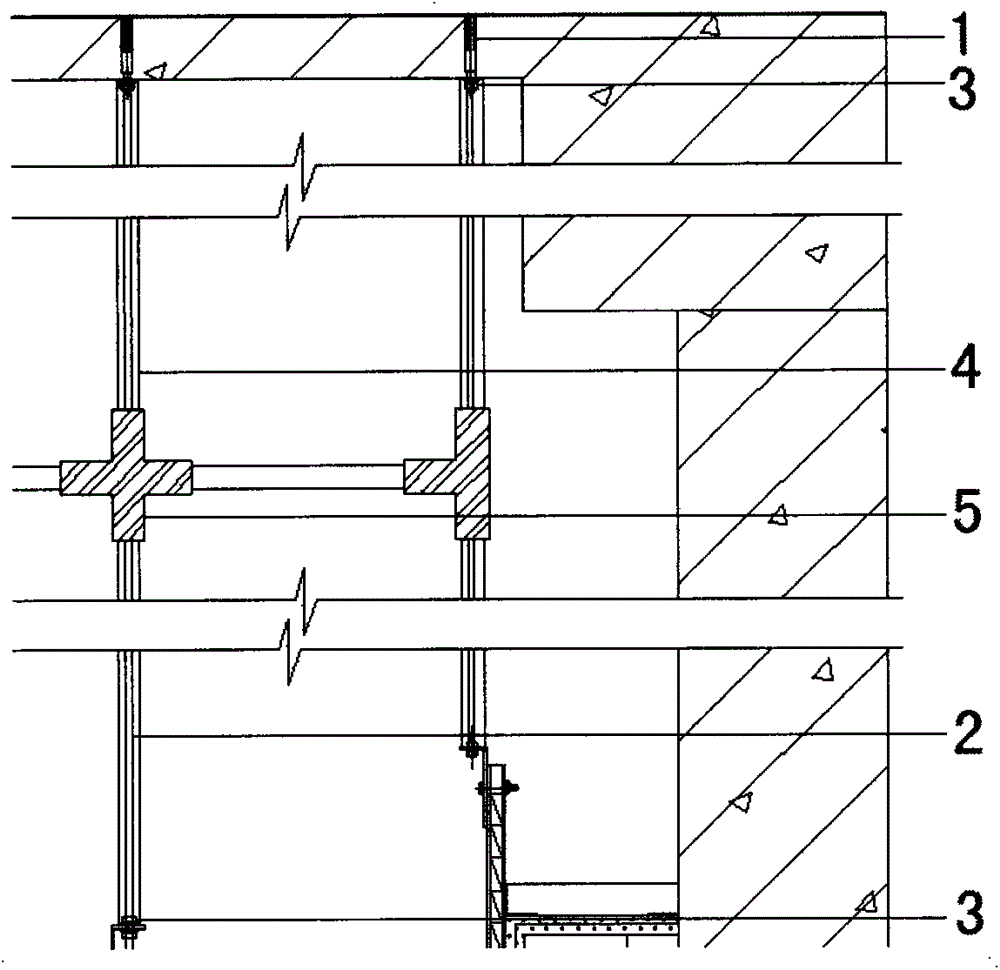

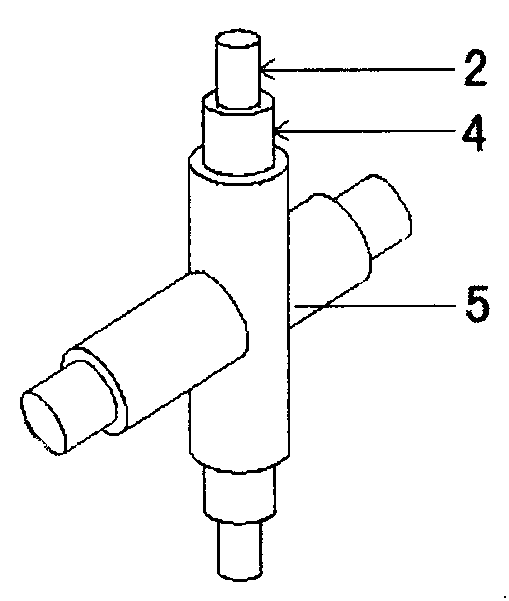

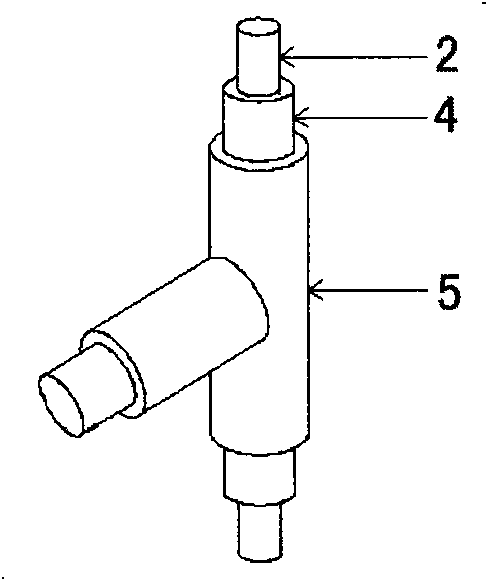

[0023] Example: such as figure 1 , Figure 5 As shown, a super-sized hanging and stable structure in the inner space of the suspended ceiling, which includes a screw rod 2, a socket buckle-type thin-walled steel conduit 4, the screw rod 2 is a solid screw rod with full teeth, and the upper end is fixed on the top surface of the floor by an expansion bolt 1. The threaded mandrel 2 is provided with a socket buckle type thin-walled steel conduit 4, and the two ends of the socketed buckle type thin-walled steel conduit 4 are fixed on the threaded rod 2 through the nut 3.

[0024] The socket buckle-type thin-walled steel conduit 4 set by the screw rod 2 is composed of two or more socket-type buckle-type thin-wall steel conduit units connected, and the adjacent socket-type buckle-type thin-wall steel conduit units are connected through the sleeve buckle-type thin-wall steel conduit new joint 5 Make a docking.

[0025] The new connector 5 of the socket buckle-type thin-walled steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com