Moisture regaining feed-forward control method based on supplied material water content differences

A technology of feedforward control and moisture content, applied in ratio control, self-adaptive control, general control system, etc., can solve the problem that the moisture content of loose and moisture-recovered materials does not participate in feedback control, etc., achieve short delay and improve response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

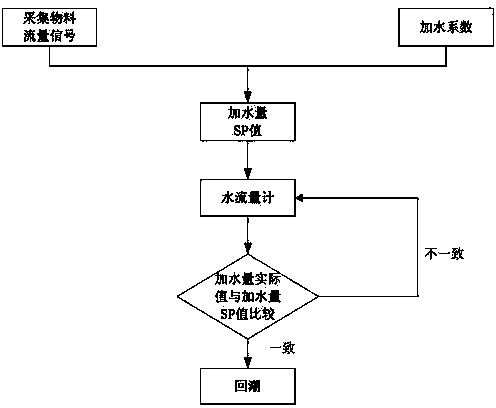

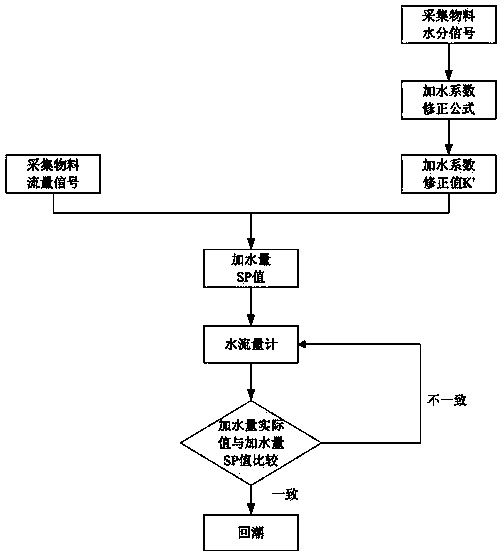

Method used

Image

Examples

Embodiment 1

[0026] The tobacco leaf that the present embodiment adopts is the B module of Yunyan (soft precious product) brand, and it comprises the following steps:

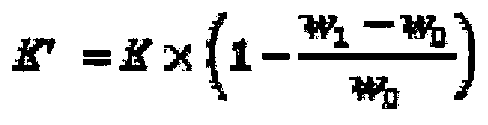

[0027] 1. The loose moisture regain drum collects the moisture signal of the material (w 1 ), w 1 Between 10-13%; then compare the material moisture signal (w 1 ) and the set value of material moisture content (w 0 ), the water addition coefficient K (K=6%) is corrected by the water addition coefficient correction formula to obtain the water addition coefficient correction value K', the formula is as follows:

[0028] K ′ = K × ( 1 - w 1 - w 0 w 0 )

[0029] w 0 =12%

[0030] After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com