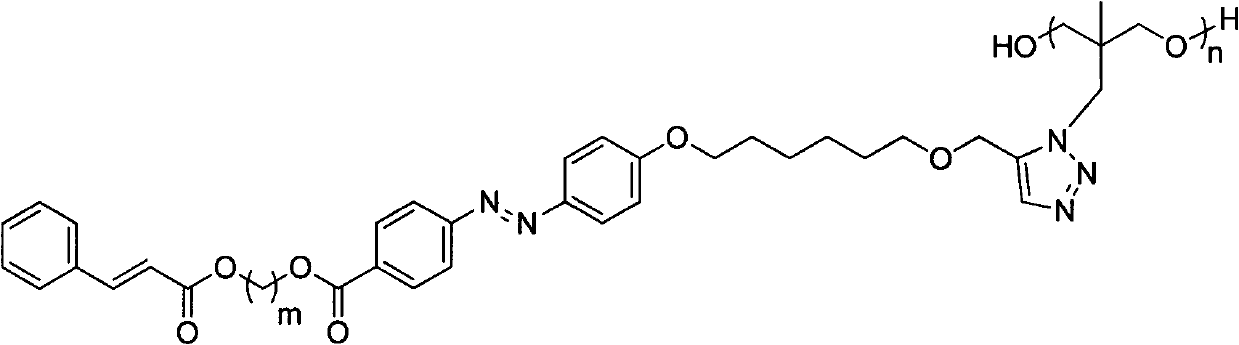

Azobenzene and cinnamic acid ester group-containing side-chain-type liquid crystal polymer membrane material and synthetic method therefor

A side chain type liquid crystal, cinnamate technology, applied in liquid crystal materials, chemical instruments and methods, organic chemistry and other directions, can solve the problems of difficult to improve the viewing angle of liquid crystal display, difficult multi-domain process, easy to damage color display filter film and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Synthesis of 4-(4-hydroxyphenyl)azobenzoic acid

[0024] Under an ice-water bath, a 30 mL aqueous solution of sodium nitrite (3.8 g, 55.0 mmol) was added dropwise to p-aminobenzoic acid (6.9 g, 50.0 mmol) hydrochloric acid solution (14 mL concentrated hydrochloric acid and 60 mL distilled water). After stirring in an ice-water bath for 30 minutes, the above mixture was poured into 80 mL of an aqueous solution of phenol (4.7 g, 50.0 mmol) and sodium hydroxide (6.9 g, 172.0 mmol), and continued stirring in an ice-water bath for 2 hours. After neutralization, the crude product was obtained by suction filtration, washed successively with distilled water and absolute ethanol, recrystallized with 4% aqueous sodium bicarbonate solution, and vacuum-dried at 50°C to obtain 10.2 g of dark red needle-like crystals with a yield of 84%.

[0025] Synthesis of Cinnamoyl Chloride

[0026] Add cinnamic acid (9.9g, 67.0mmol) and 12mL thionyl chloride to a 50mL round bottom flask and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com