Paste taking components and packaging

A paste and component technology, applied in the field of paste taking components and packaging, can solve the problems of easy-to-pollute paste, cannot be practical, and cannot seal paste, etc., to ensure reliability and sustainability, and to achieve practicality. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Such as figure 1 , 4 As shown, the paste taking package of this embodiment includes a paste taking assembly 1 , a container 2 , and a top cover 5 , and the top cover 5 is detachably connected to the container opening of the container 2 .

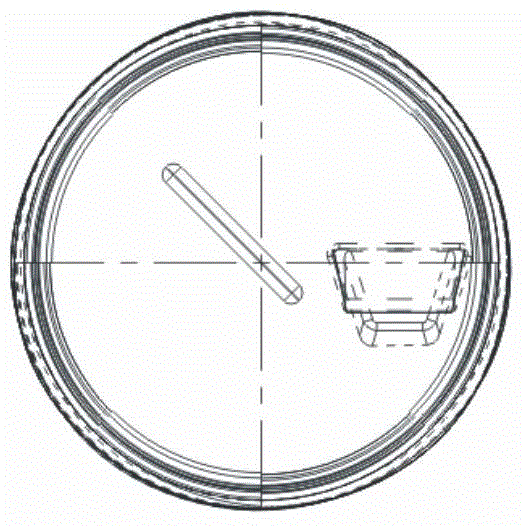

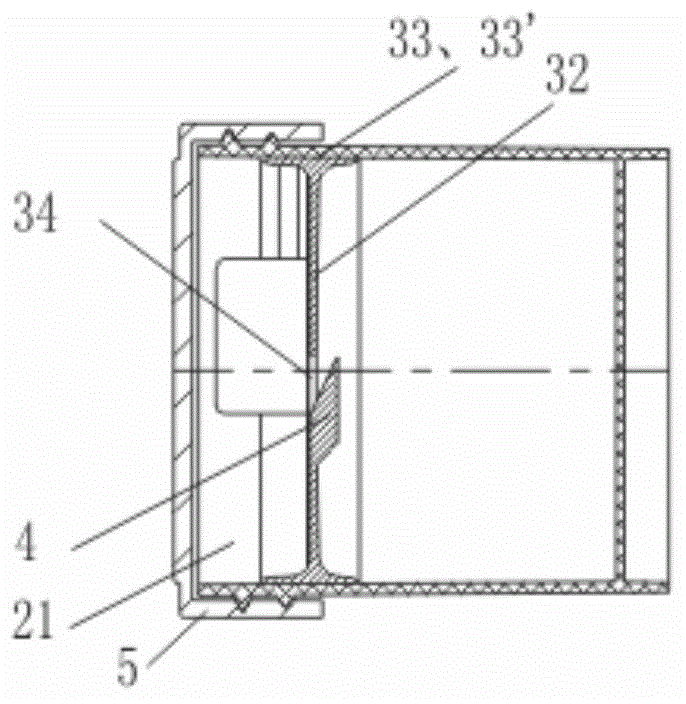

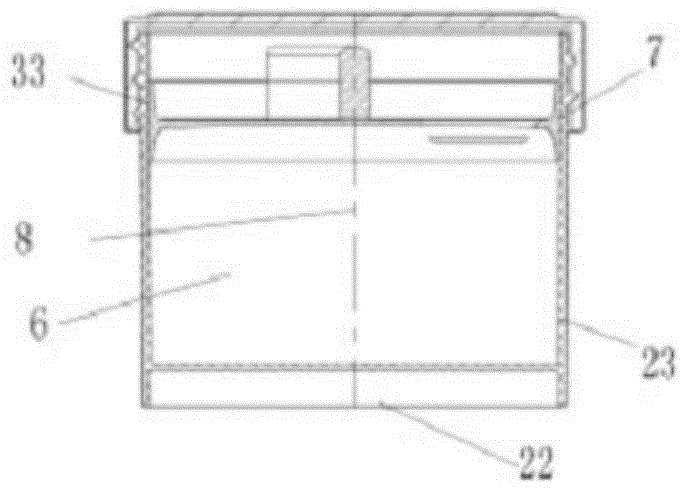

[0063] Such as figure 2 , 3 , 6, and 9, the paste taking assembly 1 includes a taking cover 3 that can stick to the paste 6, and the taking cover 3 is embodied as a rotating cover 3 in this example. The rotary cover 3 has a lower surface 32 on which the paste 6 can be attached, an upper surface 31 opposite thereto, and an outer peripheral surface 33 connecting the upper surface 31 and the lower surface 32 . An access opening 34 is formed through the upper surface 31 and the lower surface 32 , and a blade 4 is located below the access opening 34 . The blade 4 is integrally formed with the rotating cover 3 . The shovel blade 4 has a shovel surface facing the access cover 3 and used for introducing the paste 6 into the access open...

Embodiment 2

[0077] Such as Figure 25-33 As shown, the paste taking package of this embodiment differs from that of Embodiment 1 in that the limiting structure 7 is realized by setting three pillars on the hard skeleton 9, and the outer edge of the hard skeleton 9 is provided with a thinner The soft elastic body 13, the columns and the soft elastic body 13 are in contact with the inner wall 23 of the container to form a side contact surface 33', and the lower edge of the soft elastic body 13 also has a thin-walled eave-like structure 37. The side contact surface 33' in the first embodiment is a continuous and regular strip, while the side contact surface 33' in this embodiment is irregular.

[0078] After the lid 3 is loaded into the container 2, the soft elastic body 13 and its lower elastic thin-walled eave-like structure 37 are radially deformed due to the extrusion of the container inner wall 23, and the container inner wall 23 is pressed outward, thereby Paste 6 is sealed in contain...

Embodiment 3

[0082] Such as Figure 34-39 As shown, the paste taking package of this embodiment differs from that of Embodiment 1 in that the restricting structure 7 of this example extends downwards in the vertical direction along the outer edge of the cover for taking, so that the cross section of the rotary cover 3 is "П" shape, and the restrictive structure 7 of this example is realized by the intermittent hard skeleton 9' and soft elastic body 13. The intermittent hard skeleton 9' is an elastic structure that pops up outside and is continuously The thinner soft elastic body 13 is wrapped. The advantage of such arrangement is that the skeleton is made of hard material, which can keep the restricting structure 7 to maintain its basic functions. At the same time, the hard skeleton 9' has a certain degree of elasticity, can be deformed to a certain extent, and can better adapt to the slope of the inner wall 23 of the container. changes, and the thinner soft elastic body 13 ensures the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com