Power slide device for vehicle seat

A technology for vehicle seats and sliding devices, which is applied to vehicle seats, special positions of vehicles, movable seats, etc., and can solve problems such as screw deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The described directions in the following description are defined as directions according to the arrows shown in the figures.

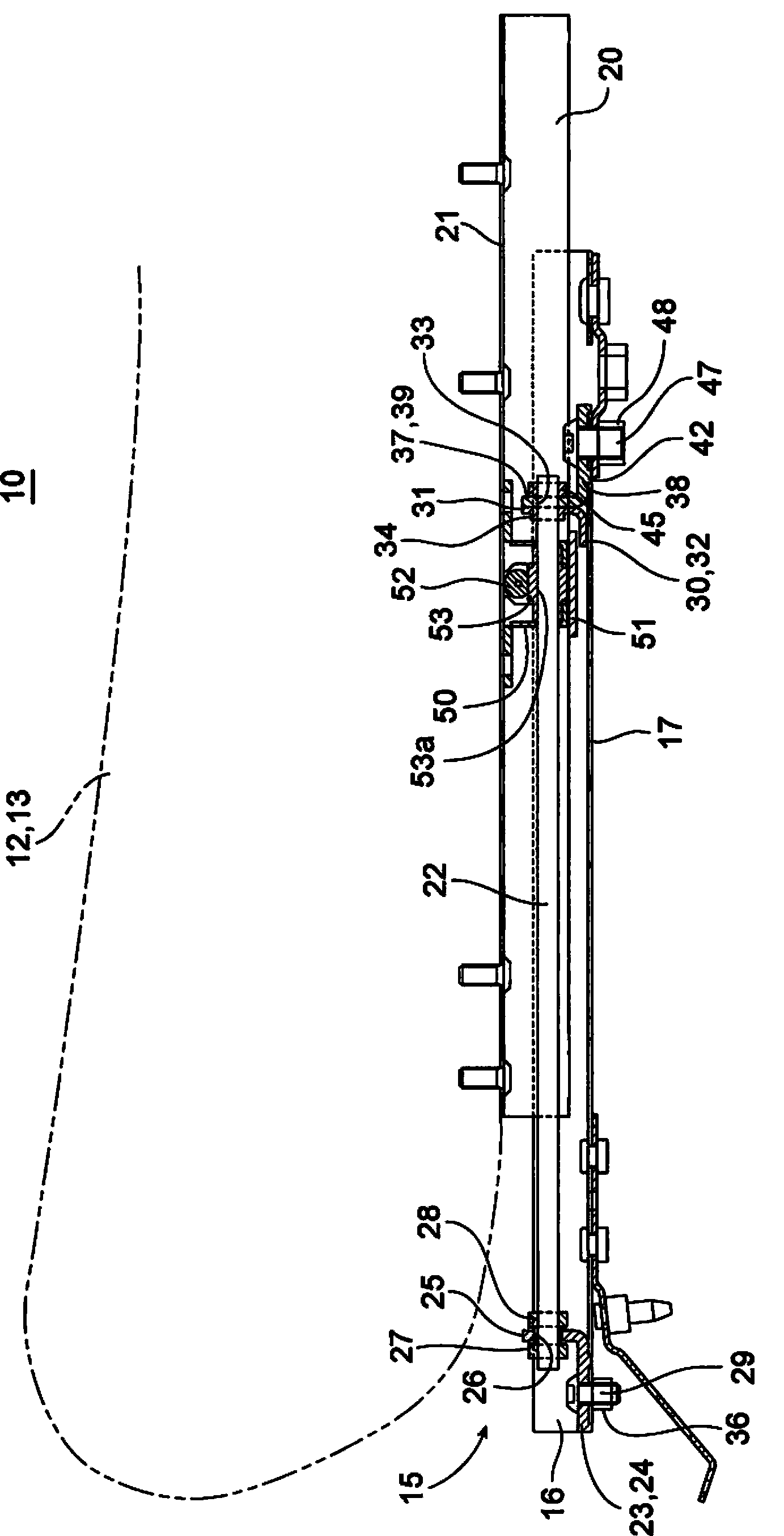

[0045] exist figure 1 The vehicle seating arrangement 10 shown in is provided with a seat 12 and a power slide 15 which is secured to the vehicle floor panel and supports a cushion 13 of the seat 12 .

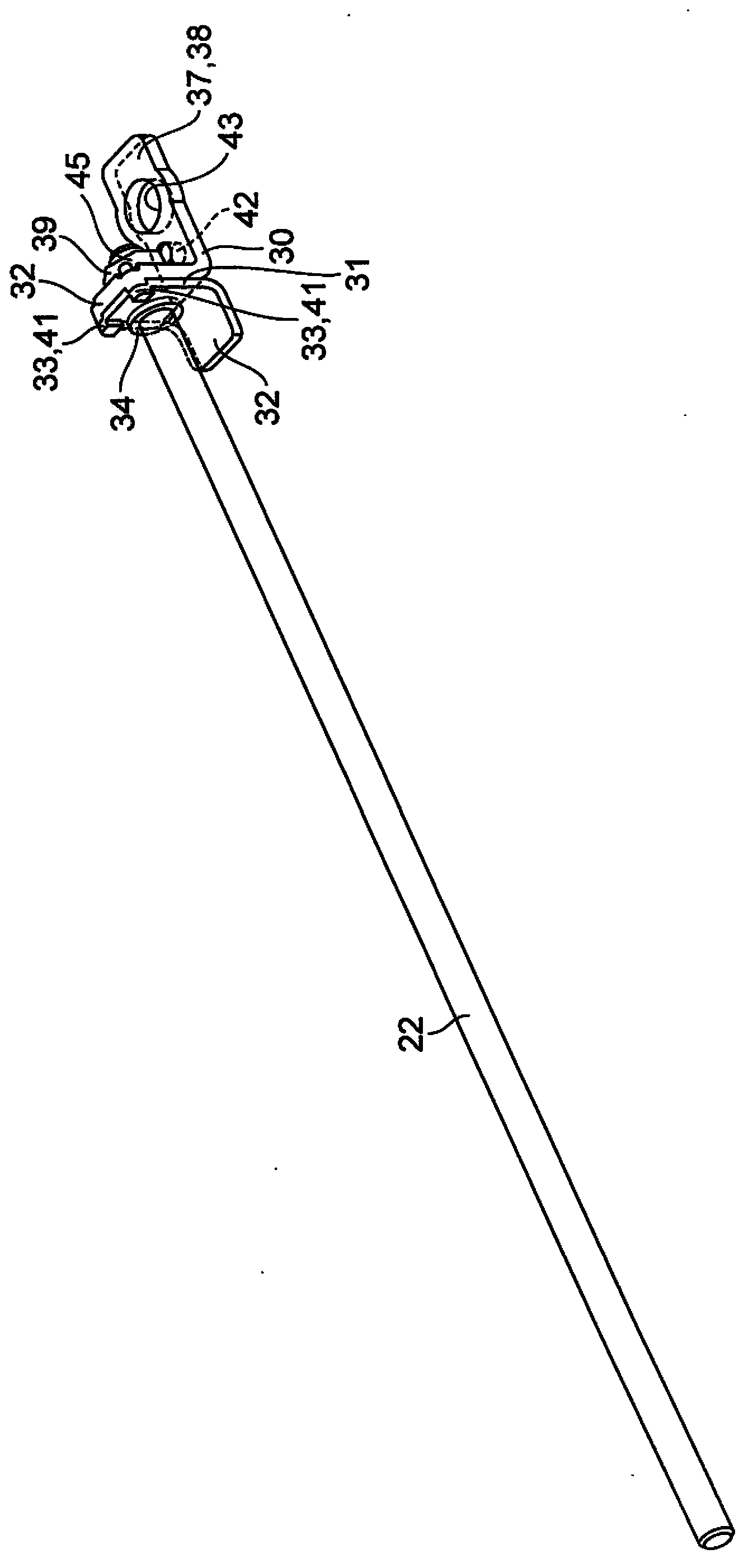

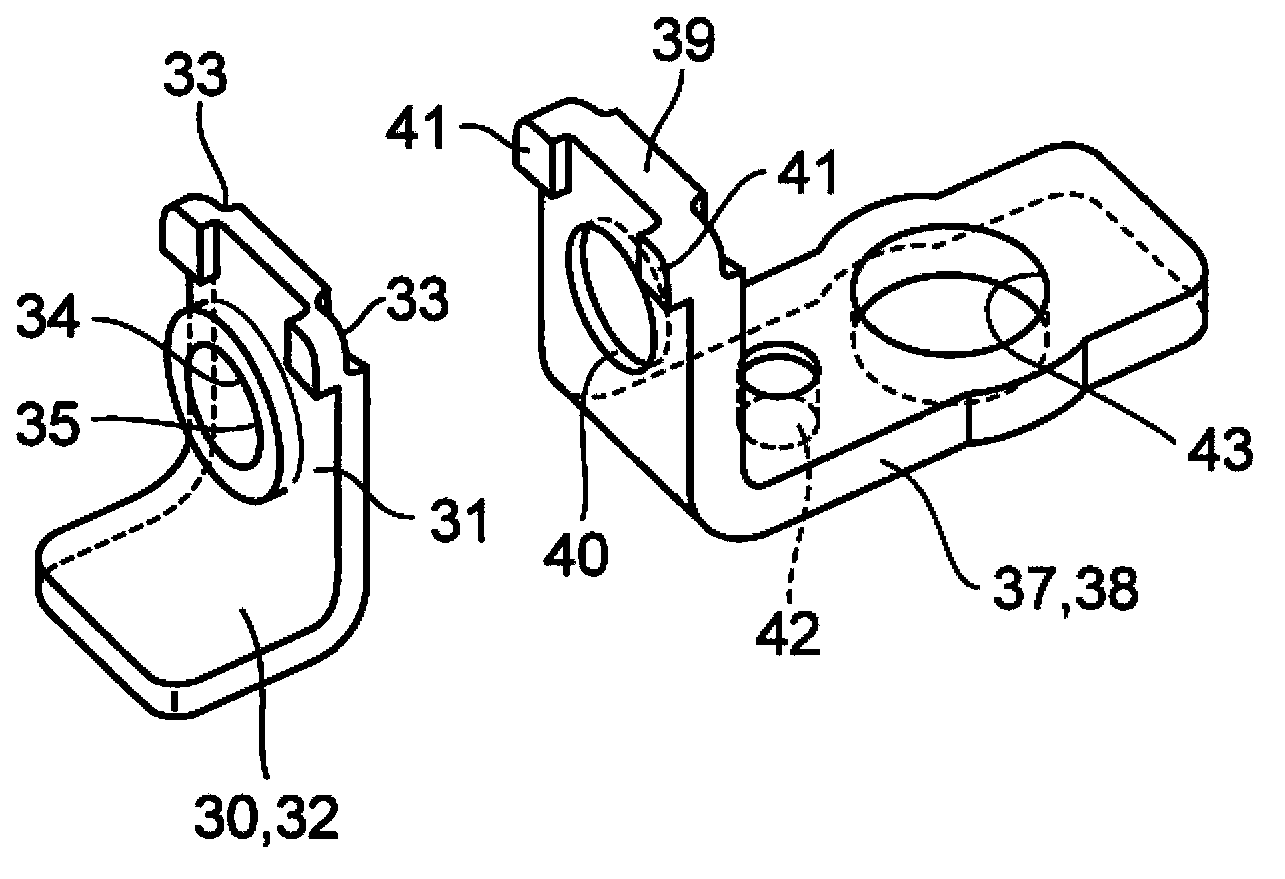

[0046] The power slide 15 is provided with a pair of left and right lower rails 16 which are fixed to the vehicle floor panel via a pair of front and rear brackets (not shown) and extend in the forward / rearward direction, and the power slide 15 is further provided with a pair of left and right lower rails 16 . The upper rails 20 are respectively mounted to the pair of lower rails 16 so as to be slidable on the lower rails 16 . Each of the lower rails 16 is a channel member made of metal, the upper side of which is open. Each lower rail 16 is provided at its bottom with a floor portion 17 having the shape of a horizontal plate, which is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com