Combined gold-stamping embossing pressure compensation plate-adjusting-free technology

A pressure compensation, combined technology, applied in gold powder printing, printing, rotary printing machines and other directions, can solve the problems of wasting time and labor intensity, and achieve the effect of improving work efficiency, easy operation, and simplifying the plate adjustment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

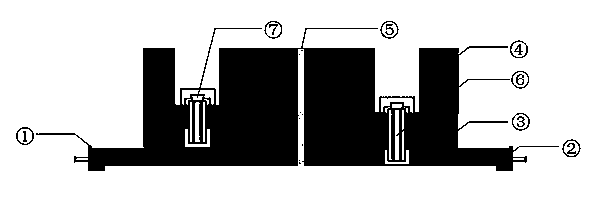

[0008] Such as figure 1 As shown, the aluminum bottom plate 2 with the positioning pin 5 is fixed on the top of the frame plate frame 1 of the hot stamping and raised part of the hot stamping machine or the die-cutting machine, and the iron plate 3 is fixed on the aluminum bottom plate 2 by screws 6, and the hot stamping Raised copper plate 4 is fixed on the iron plate 3 by screw two 7. Before production, first check the gauge, determine the position of the positioning pin 5 according to the position of the printed matter pattern, connect the iron plate 3 to the positioning pin 5 and fix it, and then connect the bronzing raised copper plate 4 to the positioning pin 5 and align it with the printed matter After matching the patterns, fix them on the iron plate 3 to complete the adjustment. The second step is the pad pressing process. Remove the bronzing embossed copper plate 4 and the iron plate 3 together, and add a thin paper sheet between the iron plate 3 and the aluminum bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com