Impeller and aerator with impeller

A technology of aerator and impeller, which is applied in fish farming, application, animal husbandry and other directions, can solve problems such as affecting the effect of aeration, and achieve the effects of good product consistency, high production efficiency and simple machining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

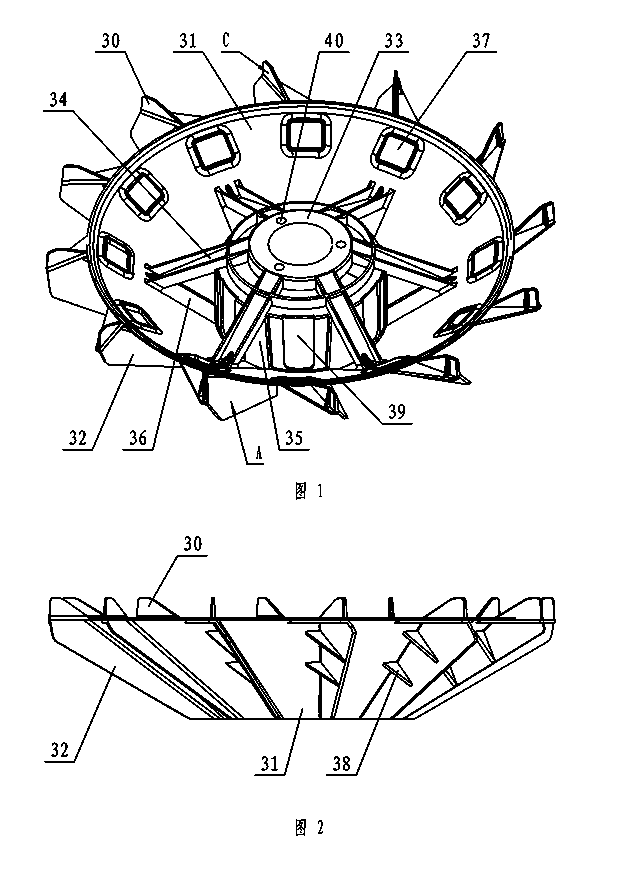

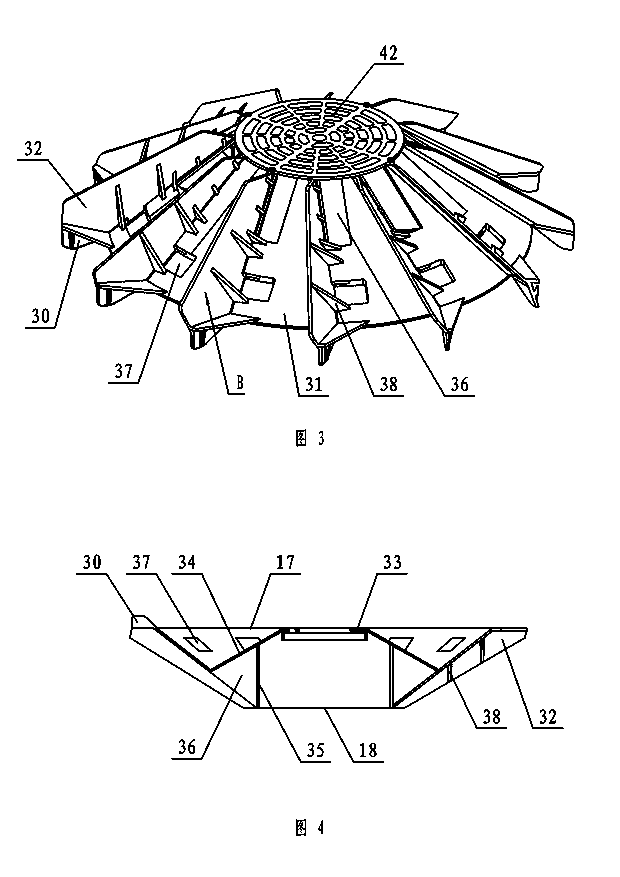

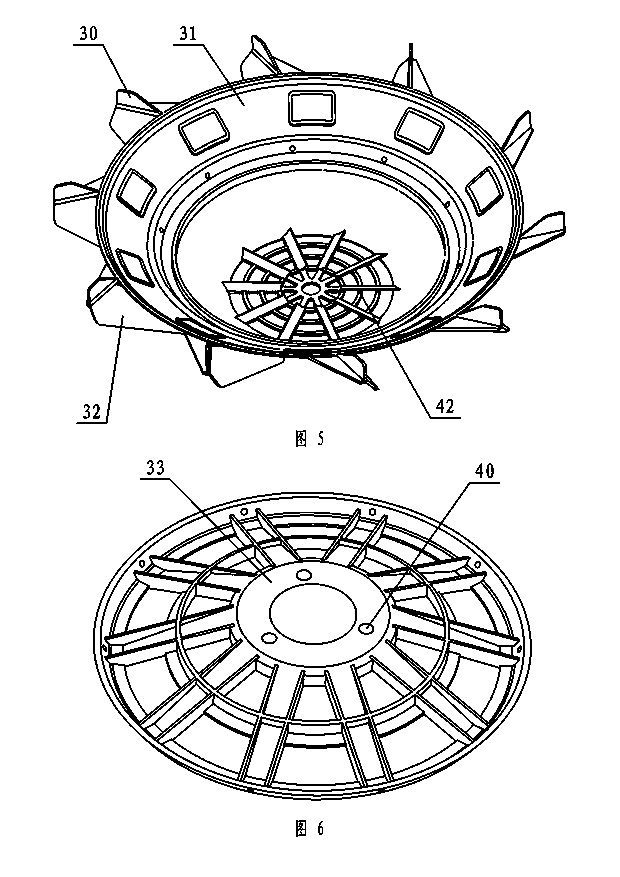

[0039] The present invention will be further described below with specific embodiment, see Figure 1-17 :

[0040] An impeller, including a cone 31, blades 32, and a fixed seat 33, the impeller is injection molded at one time, the upper end of the cone 31 is 17 large and the lower end 18 is small, the fixed seat 33 is inside the cone 31, and the fixed seat 33 has a connection with the aerator The flange 44 of the output shaft matches the connecting hole 40. There are a plurality of blades 32 on the outside of the cone 31. The blades 32 and the cone 31 are obliquely combined. The water board 30, the working surface C of the paddle board and the working surface A of the blade make a smooth transition, and the water driven by the blade 32 flows through the working surface C of the paddle board and splashes upwards, so that the water splash increases, the water body diverges, and the connection with the air is increased. Improve the oxygenation effect.

[0041] The conical body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com