Electric connector assembly, plug type connector and socket type connector

A plug-type connector, electrical connector technology, applied in the direction of two-part connection device, parts of the connection device, connection, etc., can solve the problem that the board surface is easily damaged, the clamping margin is reduced, and the clamping part is not elastic problems, to achieve easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, embodiments of the present invention will be described based on the drawings.

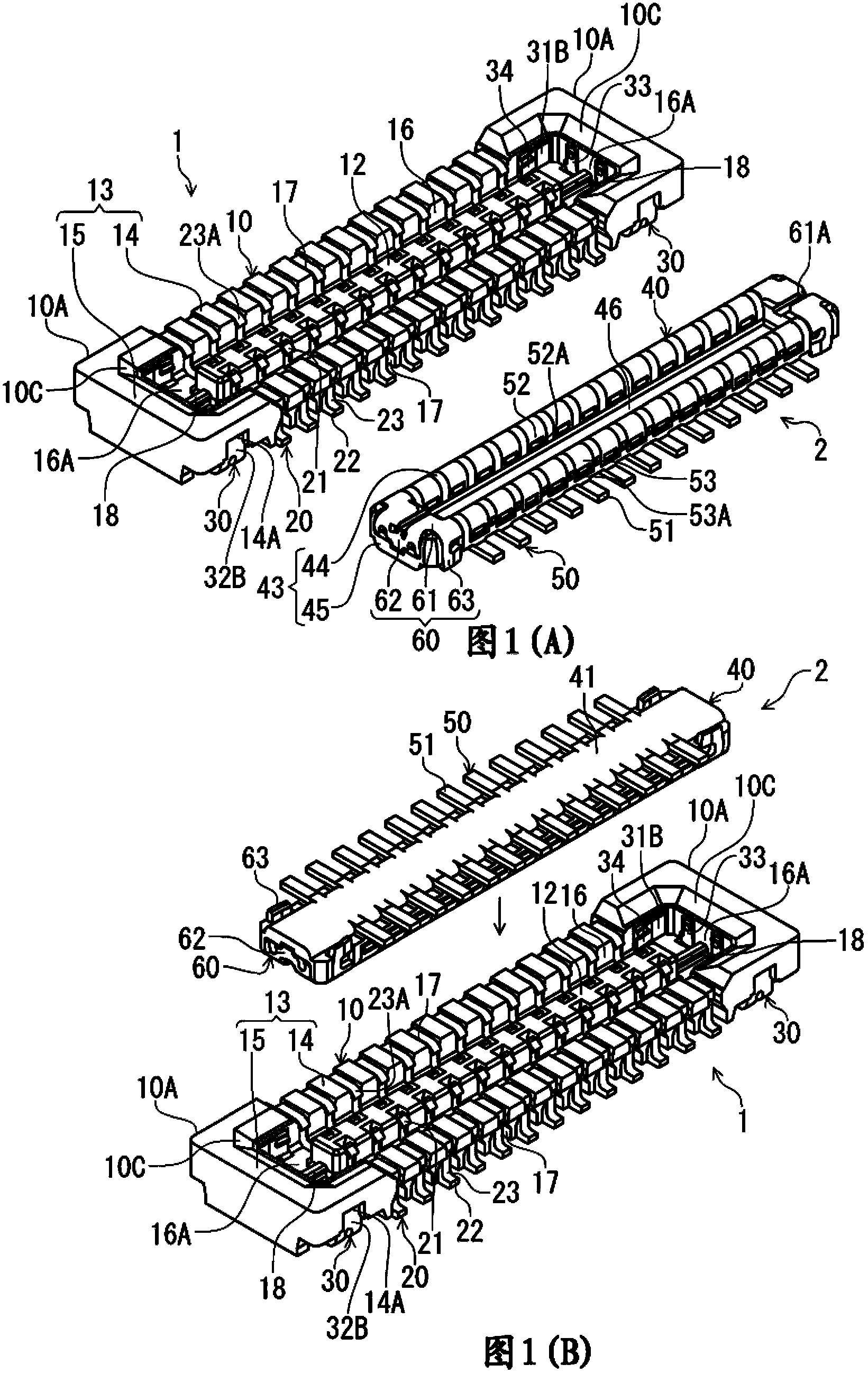

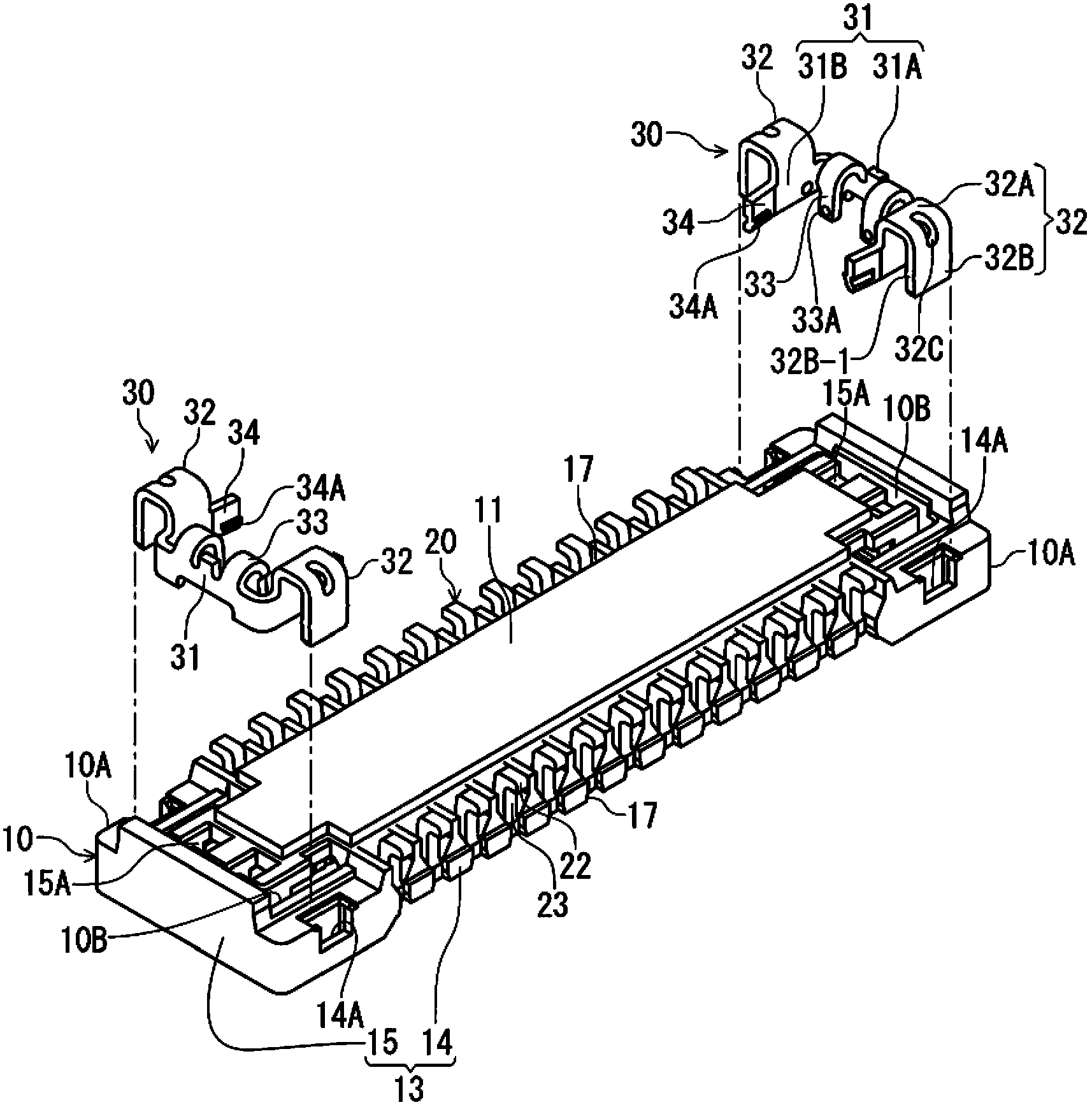

[0051] 1(A) and FIG. 1(B) are perspective views showing the whole of the receptacle connector and the plug connector according to this embodiment, and FIG. 1(A) makes the receiving spaces of the two connectors face up. Indicates that Fig. 1(B) shows the posture just before the two connectors are mated. figure 2 It is a perspective view of the receptacle connector of Fig. 1(A) and Fig. 1(B), showing the state before the locking parts are assembled. in the figure 2 1 (A) and FIG. 1 (B) are represented by reversing the receptacle connector up and down. image 3 It is a perspective view of the plug connector in Fig. 1, showing the state before the locking parts are assembled.

[0052] The receptacle connector 1 and the plug connector 2 of the present embodiment are connectors for circuit boards arranged on the mounting surfaces of different circuit boards (not shown), respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com