Solar battery

A technology for solar cells and electrodes, applied in the field of solar cells, can solve the problems of high series resistance, poor conductivity, and limitations of cells, and achieve the effect of improving conversion efficiency, good conductivity and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

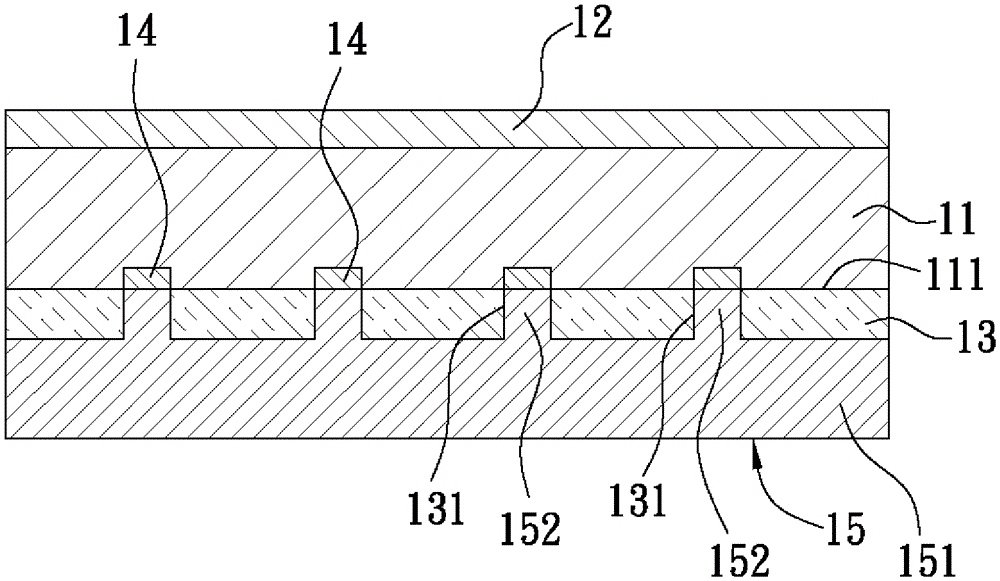

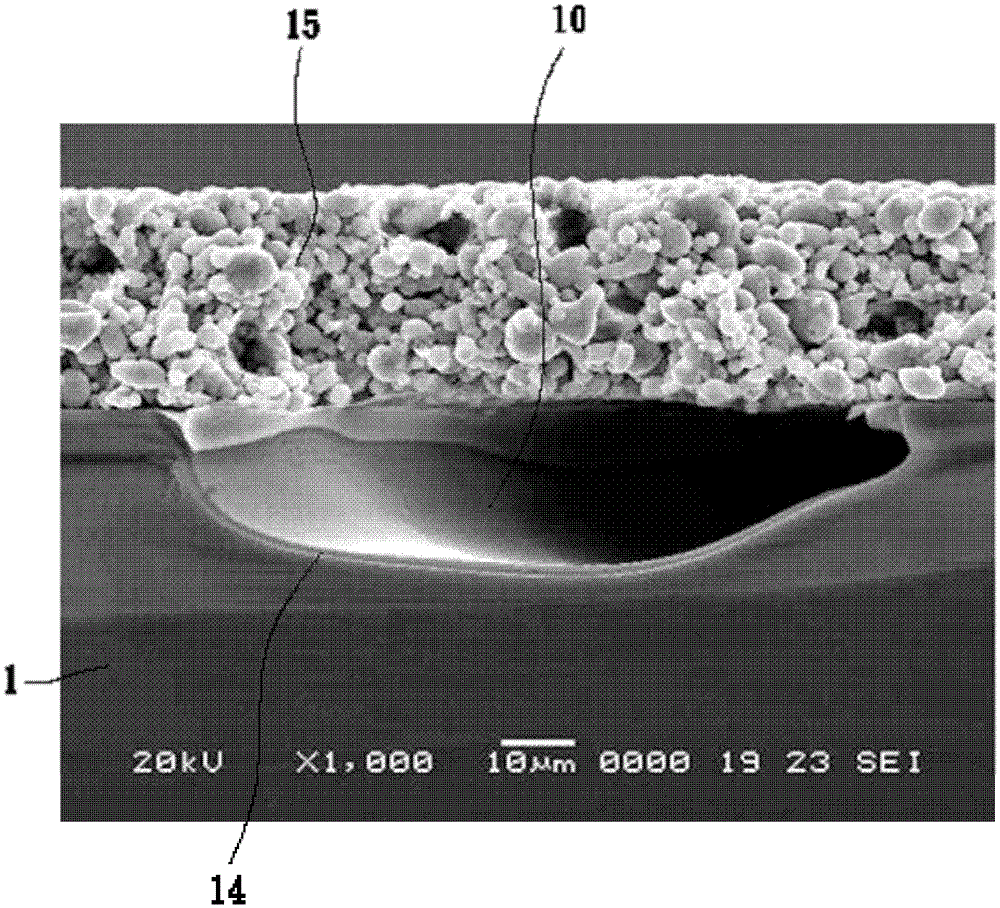

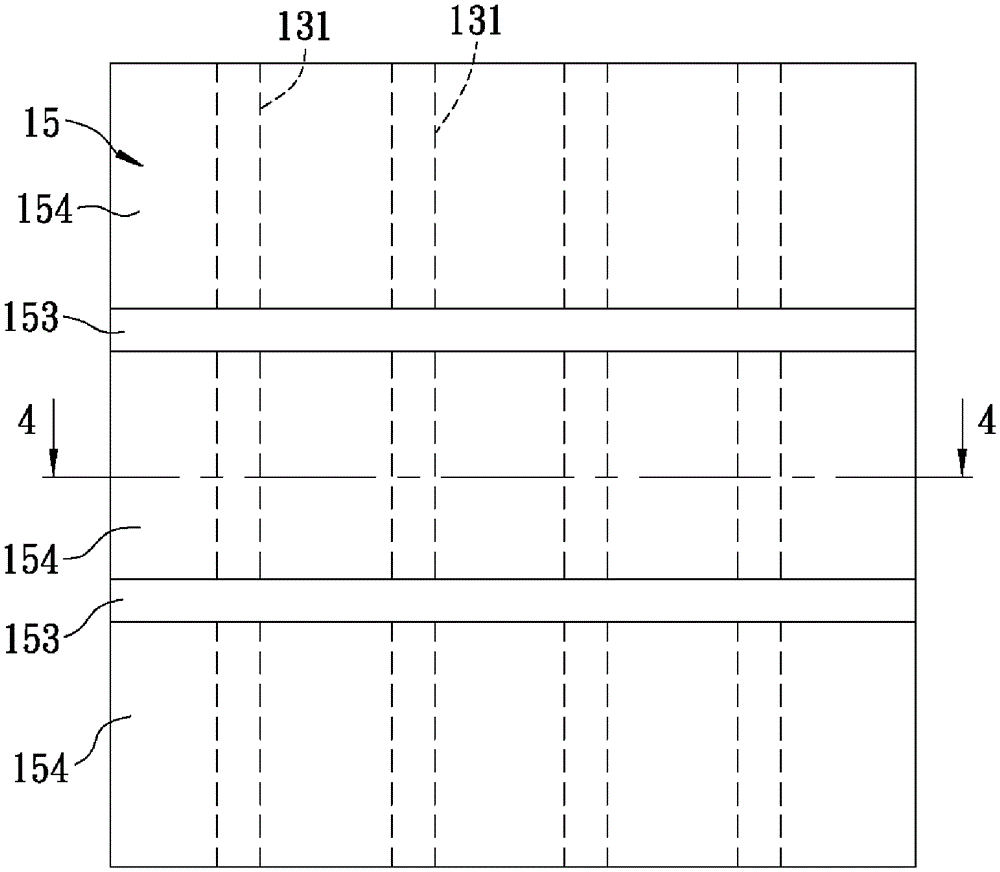

[0042] The present invention will be described in detail below with reference to the accompanying drawings and embodiments. It should be noted that in the following description, similar elements are denoted by the same numerals.

[0043] refer to Figure 7 , Figure 8 , Figure 9 , The first preferred embodiment of the solar cell of the present invention includes: a substrate 2, a dielectric layer 3, at least one through hole 31, a plurality of back electric field structures 4, an electrode 5 and at least one on the dielectric layer 3 and The opening 6 formed surrounded by the electrode 5 .

[0044] The substrate 2 includes a first surface 21 and a second surface 22 opposite to each other. The first surface 21 is a back surface, and the second surface 22 is a light-incident surface, which can be roughened to increase the amount of light incident. The substrate 2 is also provided with an emitter layer 23 located at the second surface 22 and capable of forming a p-n junction wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com