Method for rapidly adjusting production control object in ore dressing manufacturing execution system

A technology of manufacturing execution system and production control, applied in general control system, control/regulation system, adaptive control and other directions, can solve the problems of time-consuming and inefficient, inability to guarantee correctness and rationality, and chaotic organization of beneficiation production , to achieve the effect of stable stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

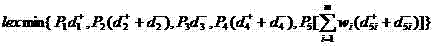

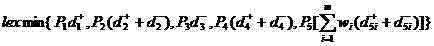

[0011] The method for quickly adjusting the production control target in the mineral processing manufacturing execution system of the present invention comprises the following steps: installing information collection terminals in the laboratory, concentrate storage, tailing storage and raw ore field of the mineral processing enterprise, and recovering the price, grade and metal of the raw ore The rate and processing cost information is transmitted to the optimization computer through the network; the total concentrate target grade issued by the ERP system , total concentrate target output , total concentrate target cost , The target beneficiation ratio of the total concentrate and the allowable consumption of various raw ores The information is transmitted to the optimization computer through the network; the optimization computer analyzes and processes the obtained data, and calculates the adjusted target grade of the total concentrate , total concentrate target outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com