Plastic pipe connecting method

A connection method and technology of plastic pipes, which are applied in the direction of pipeline connection layout, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems affecting the air tightness, reliability and safety of the pipeline system, damage to the inner surface finish of the strength performance, The safety hazards of the pipeline system and other problems have been achieved, and the effects of high welding joint reliability, excellent anti-wear performance, and improved safety and reliability have been achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

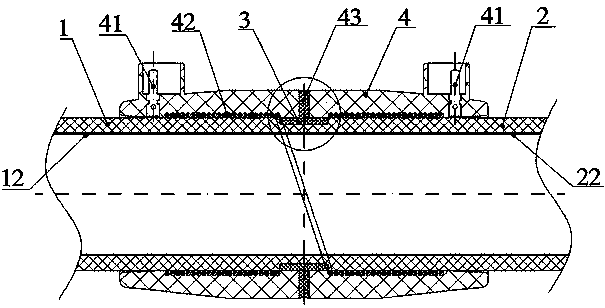

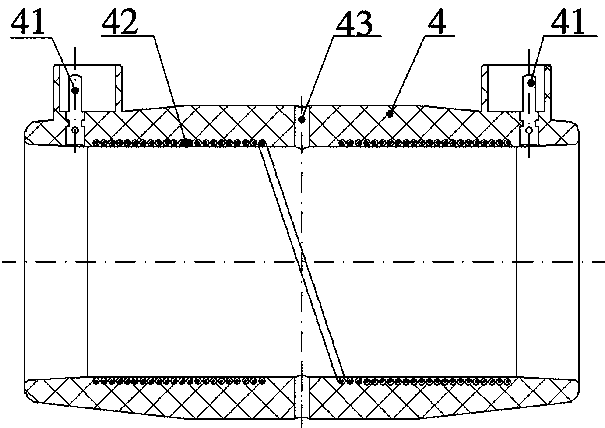

[0030] Such as Figure 1 to Figure 7 As shown, a plastic pipe connection method of the present invention includes the following steps in sequence: end treatment, hot-melt butt joint, cooling one, electric fusion butt joint, cooling two, secondary injection molding, cooling three, and smoothing the surface. In the present invention, the electrofusion casing and the two pipe fittings are welded and reinforced through three different processes of hot-melt butt joint, electric fusion butt joint and secondary injection molding. The fusion butt joint area, electric fusion fusion area and secondary injection molding area are jointly borne, which plays a protective role of triple sealing reinforcement, which can greatly improve the safety and reliability of the entire pipe fitting system, thereby prolonging the service life of the entire pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com