Spindle sealing and sand preventing isolation device for mixer of pre-impregnation tower

A shaft seal and isolation device technology, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of shaft and packing seal damage, failure to discharge, sand deposition, etc., to avoid leakage, equipment failure, and damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

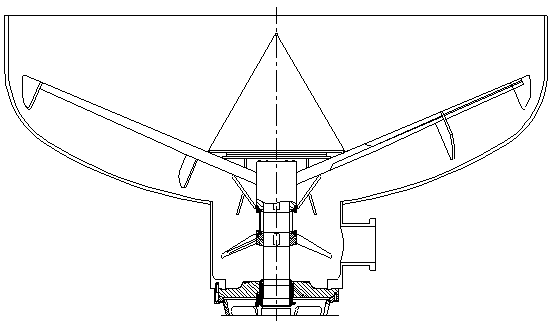

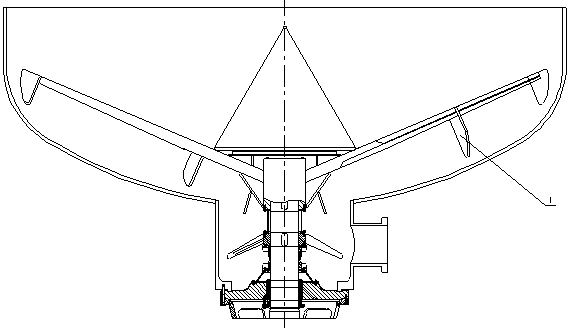

Image

Examples

Embodiment Construction

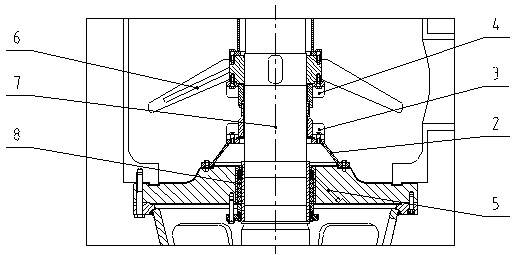

[0019] The isolation sand control cone 2 is fixed on the upper surface of the bearing chamber 5, the sealing static ring 3 is fixed on the isolation sand control cone 2 by bolts, and the sealing dynamic ring 4 is fixed on the auxiliary stirring blade 6 at the bottom by bolts. And turn. The gap between the sealing dynamic ring 4 and the sealing static ring 3 is only 1mm. Under the sealing effect of the dynamic and static rings, the packing seal 8 of the main shaft 7 is isolated from the sand, the sand cannot enter the sand protection cover, and the liquid can enter through the gap between the sealing dynamic ring 4 and the sealing static ring 3 In the sand control isolation device, the packing seal 8 is lubricated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com