Template structure and method for template support of cast-in-place concrete arc-shaped terrace

A technology of concrete and formwork, which is applied in the field of cast-in-place concrete arc-shaped ladder stand formwork structure and formwork support, can solve the problems of inconvenient guarantee of relative position and geometric size of cast-in-place concrete structure, easy deformation, large amount of deformation, etc., to achieve The formwork structure is solid and reliable, increasing the construction cost, and the effect of accurate geometric dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

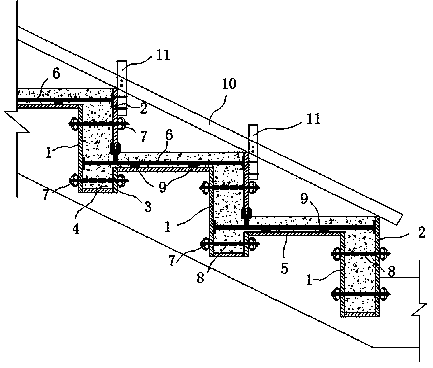

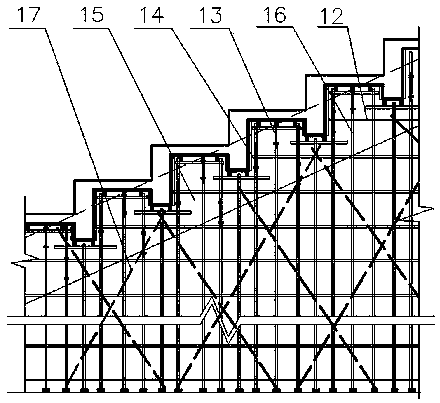

[0044] In this embodiment, a cast-in-situ concrete arc-shaped grandstand is to be built, which is composed of radial inclined beams, circumferential arc-shaped beams, and arc-shaped seat boards. The horizontal projection of the overall stand looks like a fan-shaped concentric circle, and the vertical section looks like the steps of a staircase.

[0045] The specific structure is: both ends of the curved beam and the seat board are supported on the radial slanted beam, the radial slanted beam, the curved beam, and the curved seat board are poured as a whole, and the yin and yang of the intersection of the curved beam and the seat board The angles are right angles.

[0046] The radial inclined beam is the main frame beam, the section is generally about 500×1500mm, and the angle between it and the ground is generally about 30°;

[0047] The construction of arc-shaped beams (also known as circular ribbed beams) is the key technology to be solved in this embodiment. Its horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com