Translational start-stop plane gate system for ship lock

A flat gate, opening and closing technology, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve the problem of no flat gate, and achieve the effect of simplifying the structure of the lock house, avoiding economic losses and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

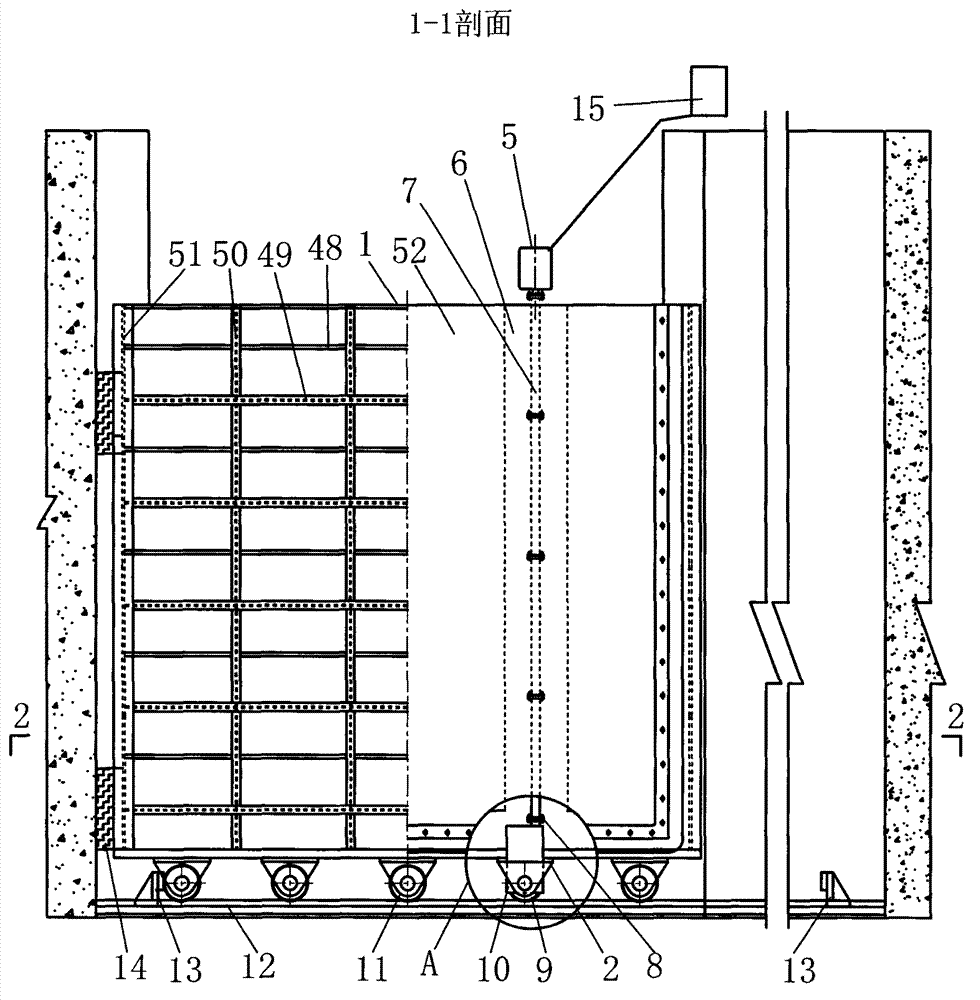

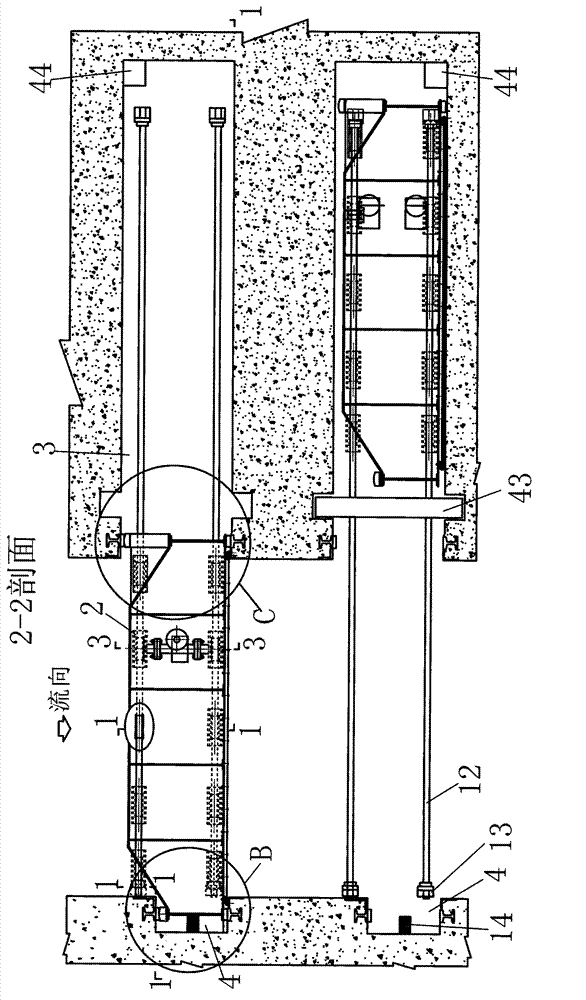

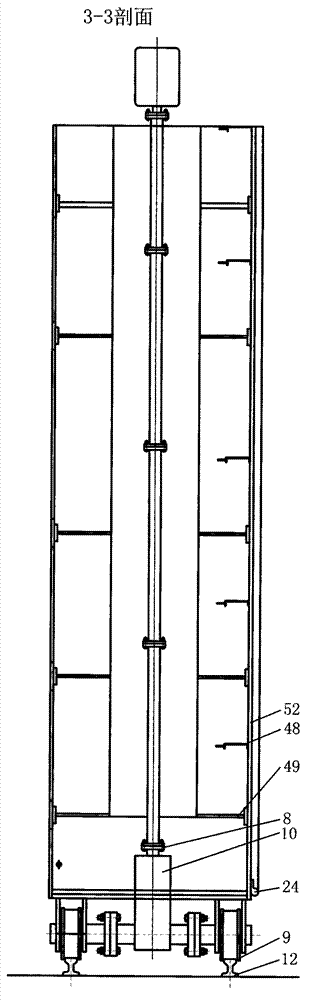

[0039] Embodiment one: see attached figure 1 , the self-propelled ship lock translation opening and closing type planar gate system is composed of a planar gate 1, a self-propelled translational opening and closing device 2, a gate slot 3, and an ordinary gate slot 4; The main beam 49, some horizontal secondary beams 48, two side columns 51, and some longitudinal beams 50 are formed; in order to adapt to the gate groove 3, the planar gate 1 is installed with a reverse slider pad 23 on the side column 51 close to the gate groove 3, The reverse slide block 18 is installed on the reverse slide block pad 23 and can slide on the reverse rail pad 17; 11. The underwater track 12, the gate limit device 13, the elastic anti-collision device 14, and the power source control system 15 are composed; the self-propelled translational opening and closing device 2 is fixedly installed at the bottom of the gate 1; The shaft device 8 and the reducer 10 transmit the torque to the driving wheel ...

Embodiment 2

[0040] Embodiment two: see attached Figure 7 , the embodiment one and the walking hoisting device are arranged above the gate, and its self-propelled hoisting device structure is made up of the main beam 25, the track 26, the hoisting trolley 27, the boom 28, and the car block 36; the hoisting trolley 27 is composed of electric control device 29, driven wheel 30, vehicle frame 31, gate height fine-tuning locking device 32, motor 33, hoist trolley reducer 34, hoist trolley drive wheel 35; 28 Suspend the plane gate 1 at a fixed height position, the electric control device 29 controls the torque generated by the rotation of the motor 33, and after being decelerated and increased by the reducer 34, it is transmitted to the driving wheel 35 to make it roll on the track 26 to drive the gate to open and close in translation .

Embodiment 3

[0041] Embodiment three: see attached Figure 8 , the mechanical push-pull translational opening and closing device in the structure of the external force traction translational opening and closing device is composed of a hoist 38, a steering wheel 39, and a wire rope 40; The hoist 38 on the side of the groove winds the steel wire rope 40, and generates a horizontal traction force on the plane gate 1 through the steering wheel 39, so that the unpowered roller 11 rolls along the underwater track 12 to the direction of the gate groove 3, and the plane gate 1 is pulled into the gate groove 3 , to realize the opening of the gate; the operation sequence is reversed when closing the gate: the hoist 38 on the 3 sides of the gate slot is in a free state without brakes, and the hoist 38 on the 4 sides of the ordinary gate slot starts the winding traction rope 40, and the plane gate is paired by the steering wheel 39 1. Generate a horizontal traction force to make the unpowered roller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com