Device for metering cast-in-place concrete of double-block ballastless track

A technology of ballastless track and metering device, which is applied in the direction of measuring device, track, laying track, etc., can solve the problems of out of control precision, unmeasured, unfavorable long-term maintenance of lines, etc., and achieve the goal of improving construction accuracy, reducing interference and time consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

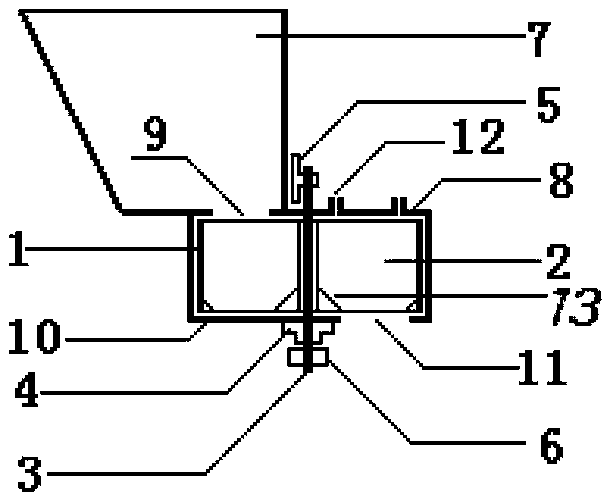

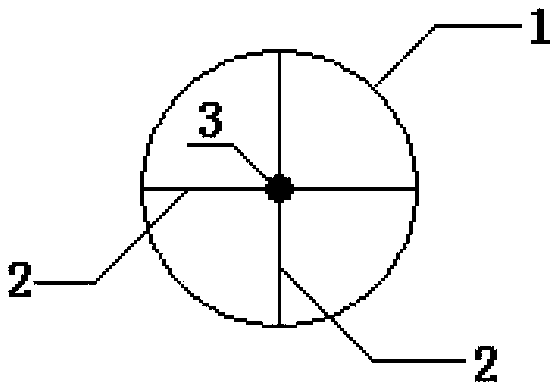

[0015] see figure 1 , figure 2 , a double-block type ballastless track cast-in-situ concrete metering device, mainly composed of a storage hopper 7, a bin metering cylinder 1, a material inlet 9, a material outlet 11, upper and lower baffle plates 8, 10 and so on. First use large-diameter steel pipes to make the annular outer wall of the sub-compartment metering cylinder 1, and use steel plates as the sub-compartment partitions 2 to be welded together with the outer wall and the rotating shaft 3 to form a rotatable sub-compartment metering cylinder 1 with a certain rigidity. Four 1 / 4 round bins distributed uniformly around the outer wall of the ring ( figure 2 ); the bottom of each bin is respectively provided with a sub-bin sliding material plate 13. Use a steel plate to make a storage hopper 7 with a slope, use a steel plate to make circular upper and lower baffles 8 and 10 respectively, set a feed inlet 9 and a ventilation hole 12 on the upper baffle 8, Open the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com