Nitrogen oxide fluorescent powder used in white-light LED, and preparation method thereof

A nitrogen oxide and phosphor technology is applied in the field of nitrogen oxide phosphor for white light LED and its preparation, which can solve the problems affecting the uniformity of product phase and morphology, the performance of phosphor samples, and the large difference in melting temperature, etc. problems, to achieve a wide range of chips, avoid performance deterioration, and easy post-processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

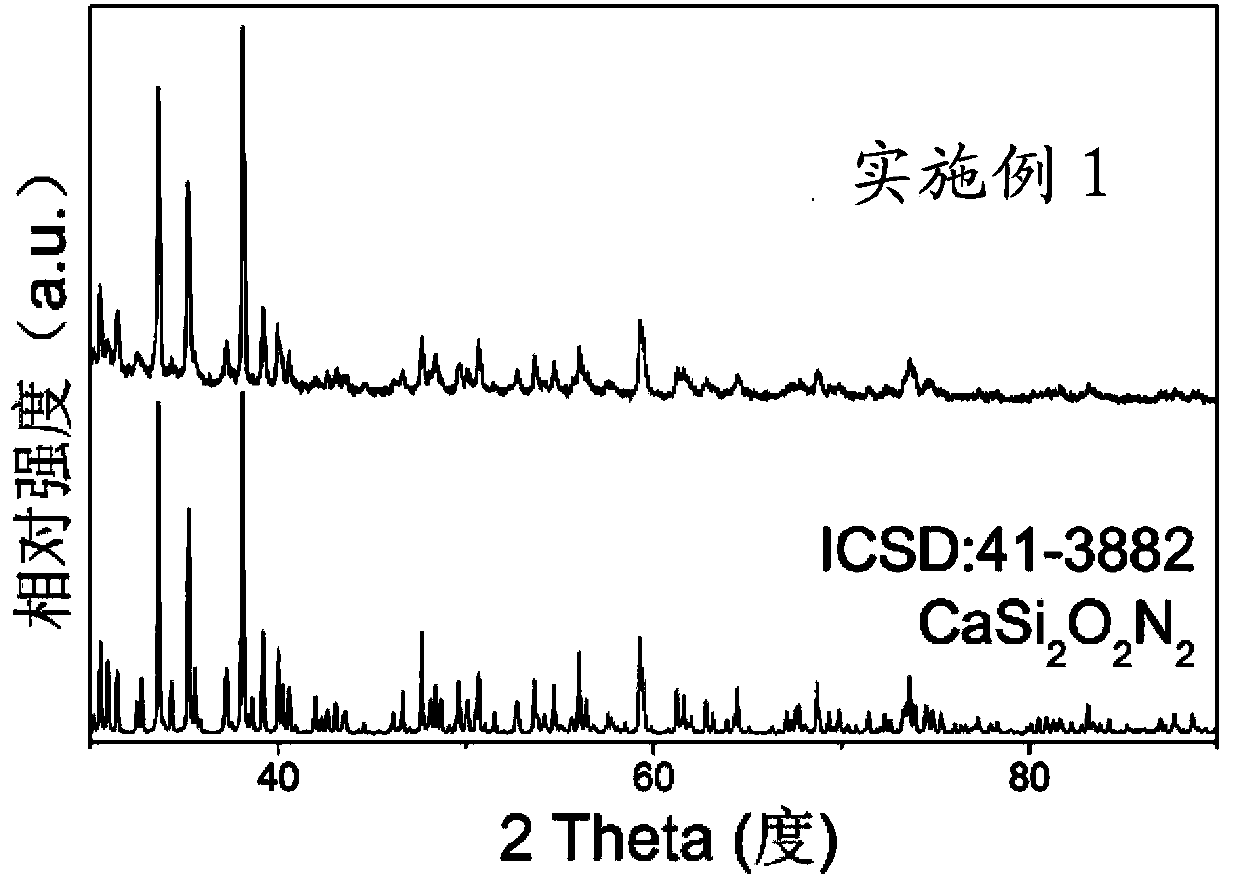

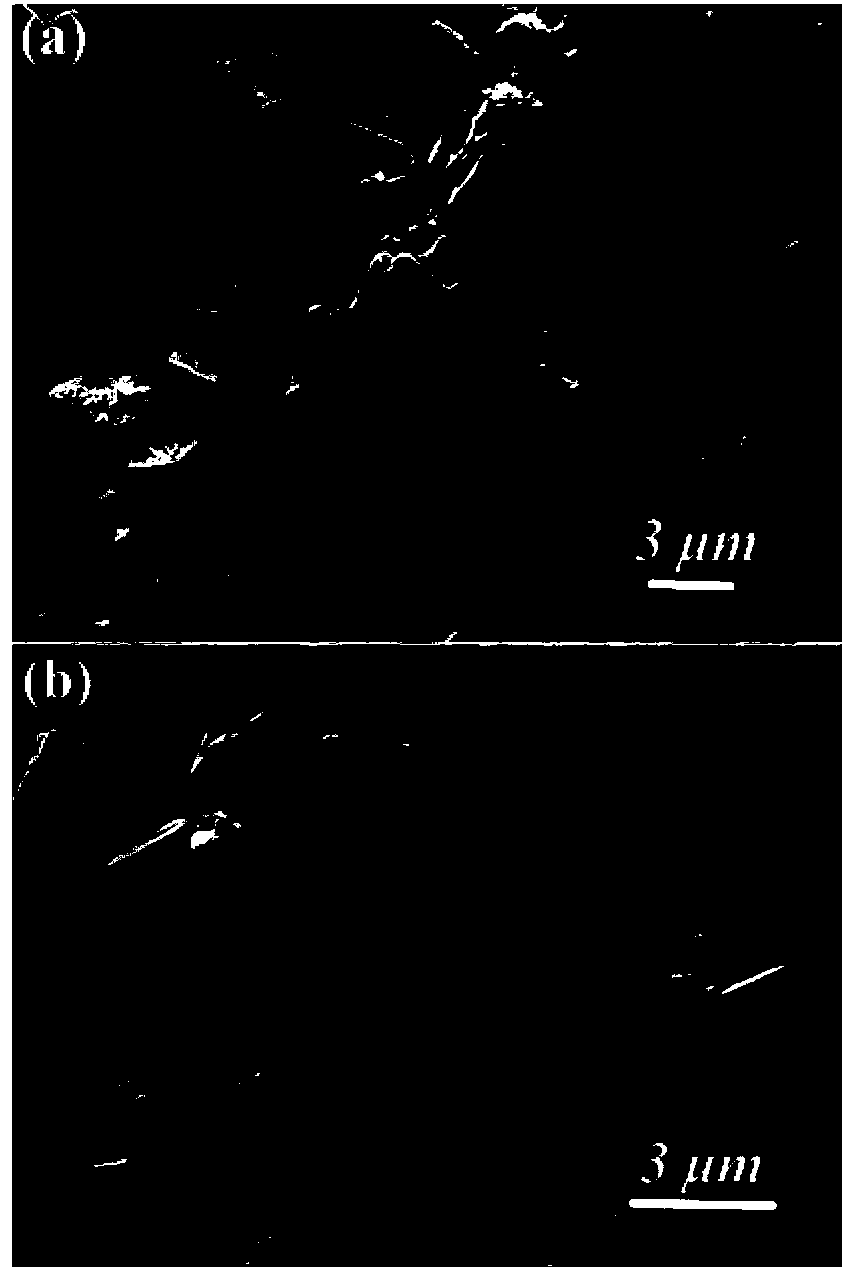

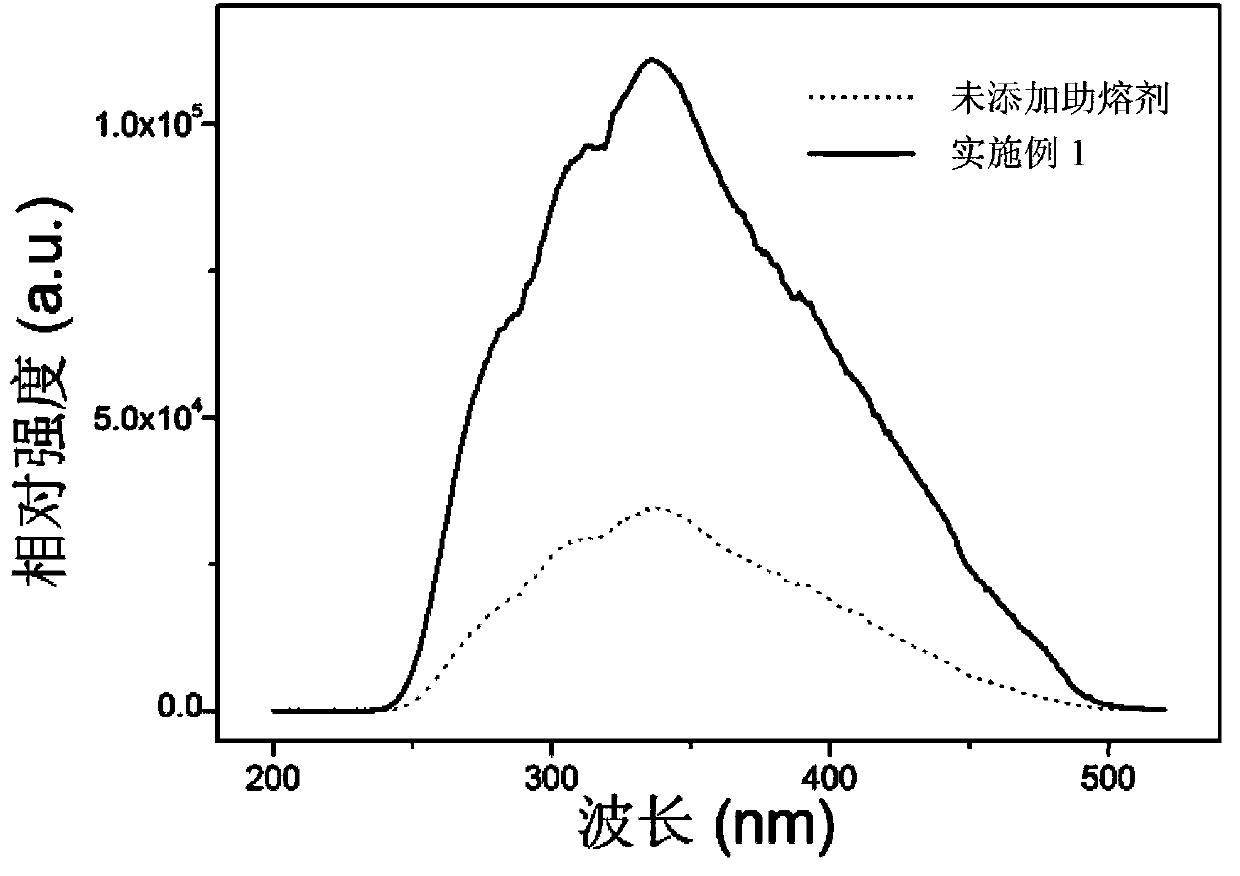

Embodiment 1

[0033] The preparation method of a kind of nitrogen oxide phosphor powder for white light LED of this embodiment comprises the following steps:

[0034] (1) Weigh and mix the raw materials; the raw materials are made of Si 3 N 4 , CaCO 3 , SiO 2 、Eu 2 o 3 Composition, the molar ratio is CaCO 3 : SiO 2 : Si 3 N 4 : Eu2 o 3 =(1-x):2-3y:y:x / 2, where x=0.03, y=2 / 3;

[0035] (2) Add a flux to the raw materials and mix well to obtain a mixture; the flux is Zn(CH 3 COO) 2 , the weight is 40% of the mixture;

[0036] (3) Put the mixture into the crucible and place it in the furnace tube of the horizontal high-temperature tube furnace;

[0037] (4) Vacuum the horizontal high temperature tube furnace to 10 -5 Pa, and then filled with 1 atmosphere of nitrogen with a purity greater than 99.99%;

[0038] (5) Repeat step (4) 3 times;

[0039] (6) Vacuumize the furnace to 10 -5 Pa, then fill the furnace with a reducing gas (nitrogen-hydrogen mixture) with a purity greater th...

Embodiment 2

[0050] The preparation method of a kind of nitrogen oxide phosphor powder for white light LED of this embodiment comprises the following steps:

[0051] (1) Weigh and mix the raw materials; the raw materials are made of Si 3 N 4 , CaO, SiO 2 、Eu 2 o 3 Composition, molar ratio CaO:SiO 2 : Si 3 N 4 : Eu 2 o 3 =(1-x):2-3y:y:x / 2, where x=0.005, y=0.5;

[0052] (2) Adding a flux to the raw materials and mixing to obtain a mixture; the flux is ZnO, and the weight is 50% of the mixture;

[0053] (3) Put the mixture into the crucible and place it in the furnace tube of the horizontal high-temperature tube furnace;

[0054] (4) Vacuum the horizontal high temperature tube furnace to 10 -3 After Pa, it is filled with nitrogen with a purity greater than 99.99% at 0.5 atmospheric pressure;

[0055] (5) Repeat step (4) 5 times;

[0056] (6) Vacuumize the furnace to 10 -3 After Pa, fill the furnace with reducing gas (hydrogen) with a purity greater than 99.99%;

[0057] (7) Af...

Embodiment 3

[0062] The preparation method of a kind of nitrogen oxide phosphor powder for white light LED of this embodiment comprises the following steps:

[0063] (1) Weigh and mix the raw materials; the raw materials are made of Si 3 N 4 , CaC 2 o 4 , SiO 2 、Eu 2 o 3 Composition, the molar ratio is CaC 2 o 4 : SiO 2 : Si 3 N 4 : Eu 2 o 3 =(1-x):2-3y:y:x / 2, where x=0.05, y=1 / 3;

[0064] (2) Adding a flux to the raw materials and mixing to obtain a mixture; the flux is ZnCO 3 , the weight is 30% of the mixture;

[0065] (3) Put the mixture into the crucible and place it in the furnace tube of the horizontal high-temperature tube furnace;

[0066] (4) Vacuum the horizontal high temperature tube furnace to 10 -1 Pa, and then filled with 2 atmospheres of nitrogen with a purity greater than 99.99%;

[0067] (5) Repeat step (4) 4 times;

[0068] (6) Vacuumize the furnace to 10 -1 After Pa, fill the furnace with reducing gas (ammonia) with a purity greater than 99.99%;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com