Continuous liquid-phase catalytic hydrogenation reduction method for production of o-chloroaniline

An o-chloroaniline, liquid-phase catalysis technology, applied in chemical instruments and methods, chemical recovery, organic chemistry, etc., to achieve the effects of short process, enhanced mass transfer, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

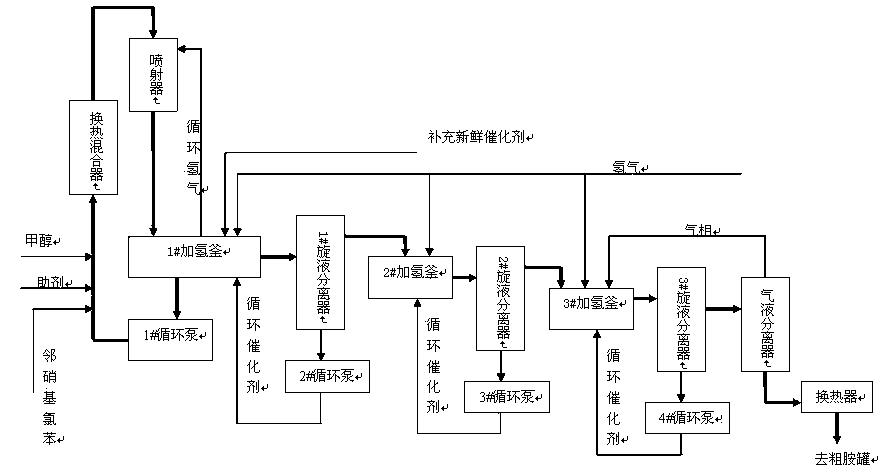

Image

Examples

Embodiment 1

[0013] Embodiment 1: produce o-chloroaniline according to the following steps

[0014] (1) Check the airtightness of the production device, make preparations before starting up, and lay the bottom material; then put a certain amount of Raney nickel catalyst into each hydrogenation tank to ensure that the hydrogenation tank is adjacent to nitrochloride The weight ratio of benzene to the catalyst reaches 3%, and then replaced with nitrogen and hydrogen in sequence;

[0015] (2) Start the material delivery pump, continuously send o-nitrochlorobenzene, methanol and additives into the 1# hydrogenation tank, and control the flow of each material; then continuously feed hydrogen, under the conditions of 50 ° C and 1.0 MPa Carry out hydrogenation reaction; part of the reaction materials in the 1# hydrogenation tank is circulated between the heat exchange mixer, injector and 1# hydrogenation tank through the 1# circulation pump, so that o-nitrochlorobenzene can be fully converted into ...

Embodiment 2

[0016] Embodiment 2: produce o-chloroaniline according to the following steps

[0017] (1) Check the airtightness of the production device, make preparations before starting up, and lay the bottom material; then put a certain amount of Raney nickel catalyst into each hydrogenation tank to ensure that the hydrogenation tank is adjacent to nitrochloride The weight ratio of benzene to the catalyst reaches 3%, and then replaced with nitrogen and hydrogen in sequence;

[0018] (2) Start the material delivery pump, continuously send o-nitrochlorobenzene, methanol and additives into the 1# hydrogenation tank, and control the flow of each material; then continuously feed hydrogen, under the conditions of 60°C and 1.0MPa Carry out hydrogenation reaction; part of the reaction materials in the 1# hydrogenation tank is circulated between the heat exchange mixer, injector and 1# hydrogenation tank through the 1# circulation pump, so that o-nitrochlorobenzene can be fully converted into o-c...

Embodiment 3

[0019] Embodiment 3: produce o-chloroaniline according to the following steps

[0020] (1) Check the airtightness of the production device, make preparations before starting up, and lay the bottom material; then put a certain amount of Raney nickel catalyst into each hydrogenation tank to ensure that the hydrogenation tank is adjacent to nitrochloride The weight ratio of benzene to the catalyst reaches 3%, and then replaced with nitrogen and hydrogen in sequence;

[0021] (2) Start the material delivery pump, continuously send o-nitrochlorobenzene, methanol and additives into the 1# hydrogenation tank, and control the flow of each material; then continuously feed hydrogen, under the conditions of 70 ° C and 1.0 MPa Carry out hydrogenation reaction; part of the reaction materials in the 1# hydrogenation tank is circulated between the heat exchange mixer, injector and 1# hydrogenation tank through the 1# circulation pump, so that o-nitrochlorobenzene can be fully converted into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com