Glass hot-bending die as well as manufacturing method and application thereof

A glass and mold technology, applied in glass hot bending molds and its manufacturing method and application field, can solve the problems of concentrated energy loss, high mold production cost, low production efficiency, etc., to reduce heat absorption, reduce production costs, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

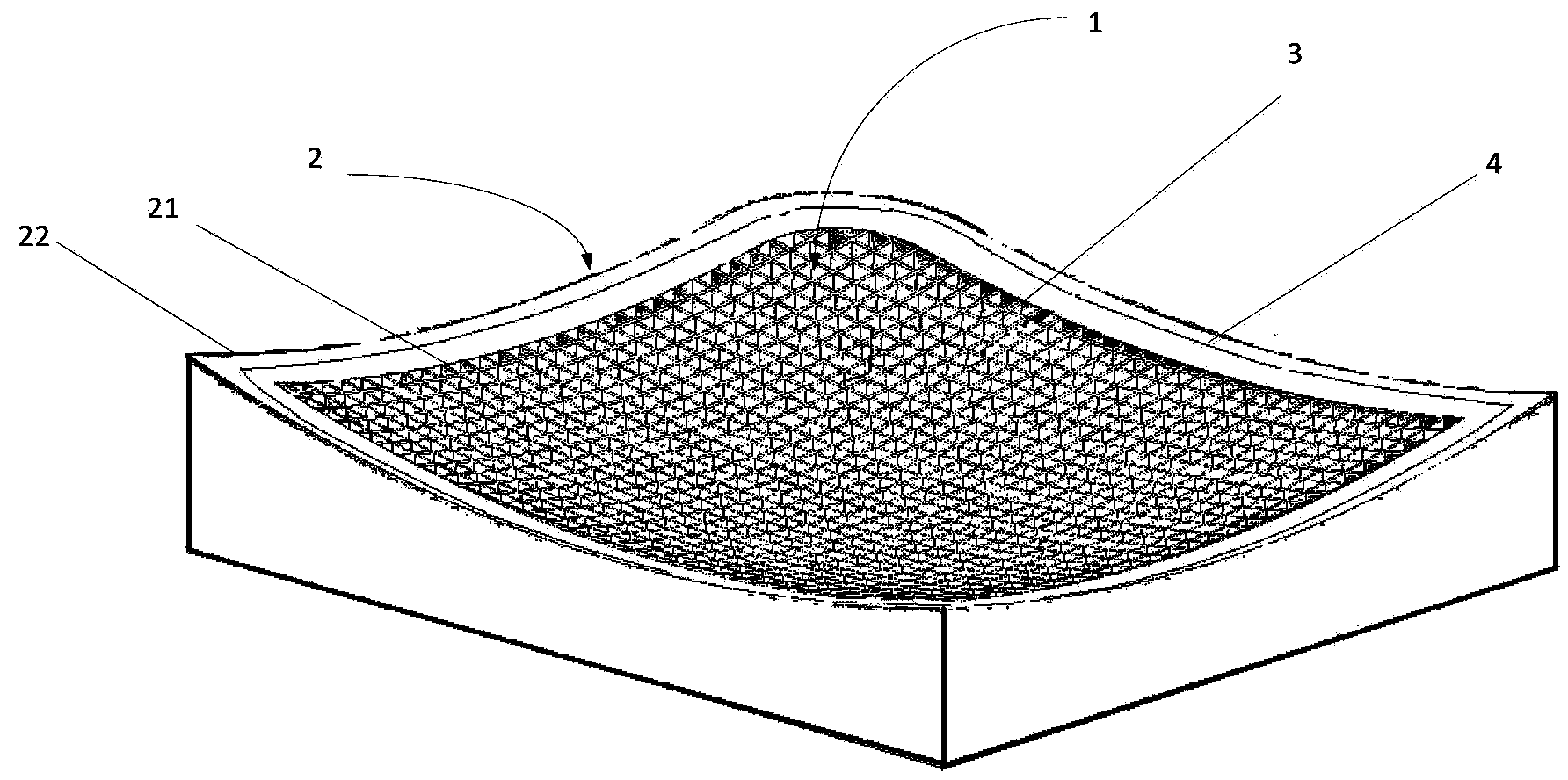

[0026] The embodiment of the present invention provides a glass hot bending mold, see figure 1 , the glass hot bending mold includes a main body 1 and a glass edge hot bending part 2 . The main body 1 is provided with a plurality of through holes 3 , and the through holes 3 pass through the upper surface and the lower surface of the main body 1 . The glass edge hot bending part 2 is a frame-type structure with uniform material, which can be covered on the periphery of the main body 1 by welding or integral molding, etc., and is used for hot bending the edge part of the glass. The size of the glass edge hot bending part 2 is determined by the The size of the hot-bent glass determines that when the glass is placed on the mould, the outer frame of the hot-bending portion 2 of the glass edge coincides with the edge of the glass or is located at the periphery of the glass, preferably at the edge of the glass. Periphery, its inner frame edge is located inside the edge of the glass,...

Embodiment 2

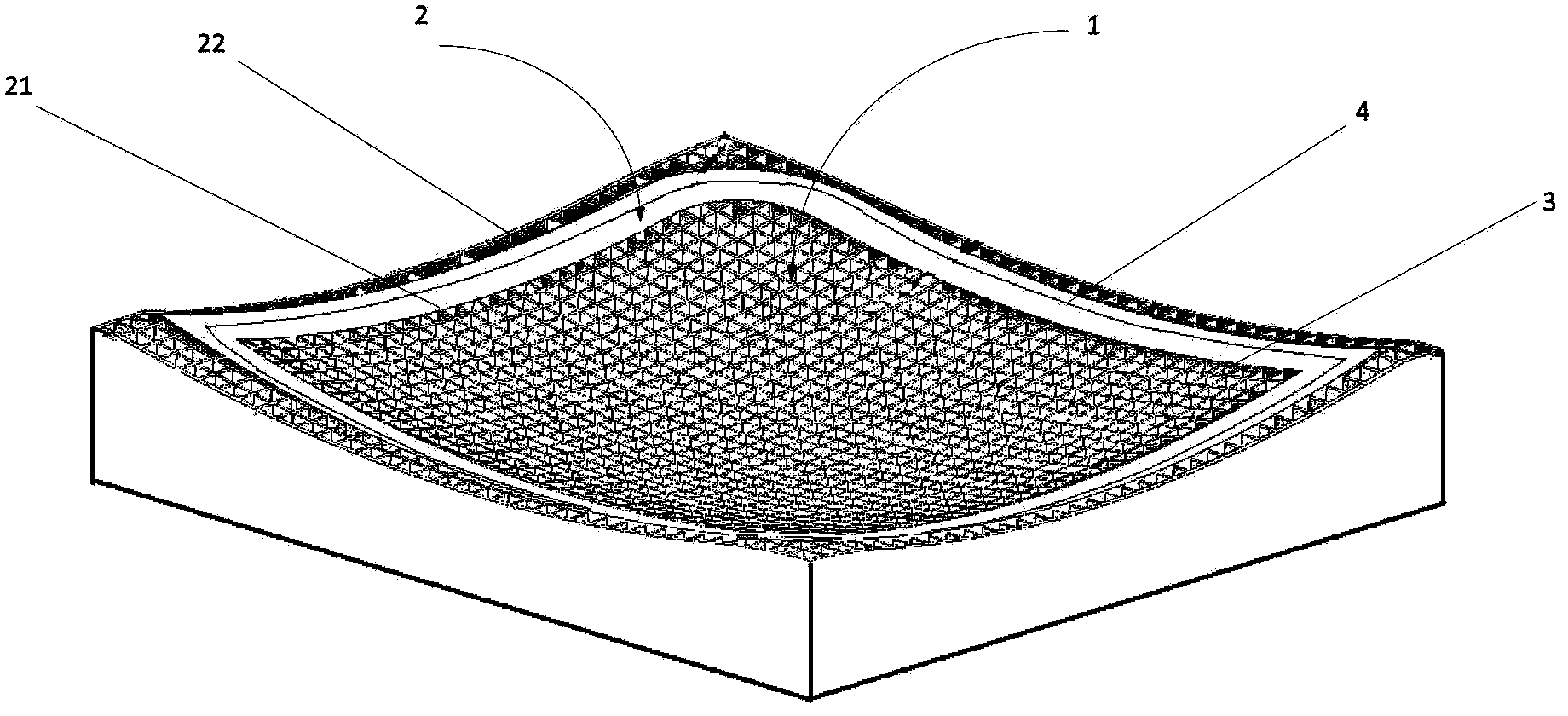

[0032] The embodiment of the present invention provides a glass hot bending mold, see figure 2 , the glass hot bending mold includes a main body 1 and a glass edge hot bending part 2 . The main body 1 is a hollow structure uniformly provided with a plurality of through holes 3, the through holes 3 run through the upper surface and the lower surface of the main body 1, and a groove (not shown in the figure) is also provided on the main body 1, and the opening of the groove Upward, the size of the groove matches the size of the glass edge hot bending part 2 for accommodating the glass edge hot bending part 2 , preferably, the groove of the main body 1 is also provided with a through hole 3 . The glass edge hot bending part 2 is a frame structure with uniform material, which is used to support and heat bend the edge part of the glass. Its size is determined by the size of the glass to be bent. When the glass is placed on the mold, the glass edge is bent The outer frame edge of ...

Embodiment 3

[0042] The embodiment of the present invention provides the manufacturing method of embodiment 2, the method comprising:

[0043] Step 1: respectively casting hot bending mold main body 1 and glass edge hot bending part 2;

[0044] see figure 2 , according to the surface design size of the molding surface, the casting mold of the mold main body 1 and the glass edge hot bending part 2 is processed, wherein the main body 1 is a hollow structure with a plurality of through holes 3 evenly provided, and the glass edge hot bending part 2 is made of uniform material The frame structure, the upper surface of the main body 1 and the upper surface of the glass edge hot bending part 2 are all processed according to the design size of the molding surface.

[0045] Step 2: Open a groove on the upper surface of the main body 1;

[0046] According to the size of the glass, determine the position where the glass to be bent is placed on the main body 1, and open a groove on the main body 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com