Full-automatic plastic lifting handle deformation device of carton lifting handle buckling machine

A carton handle and buttoning machine technology, applied in the field of machinery and equipment, can solve problems such as affecting the economic benefits of enterprises, difficult to meet product appearance requirements, damage to packaging boxes and box bodies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

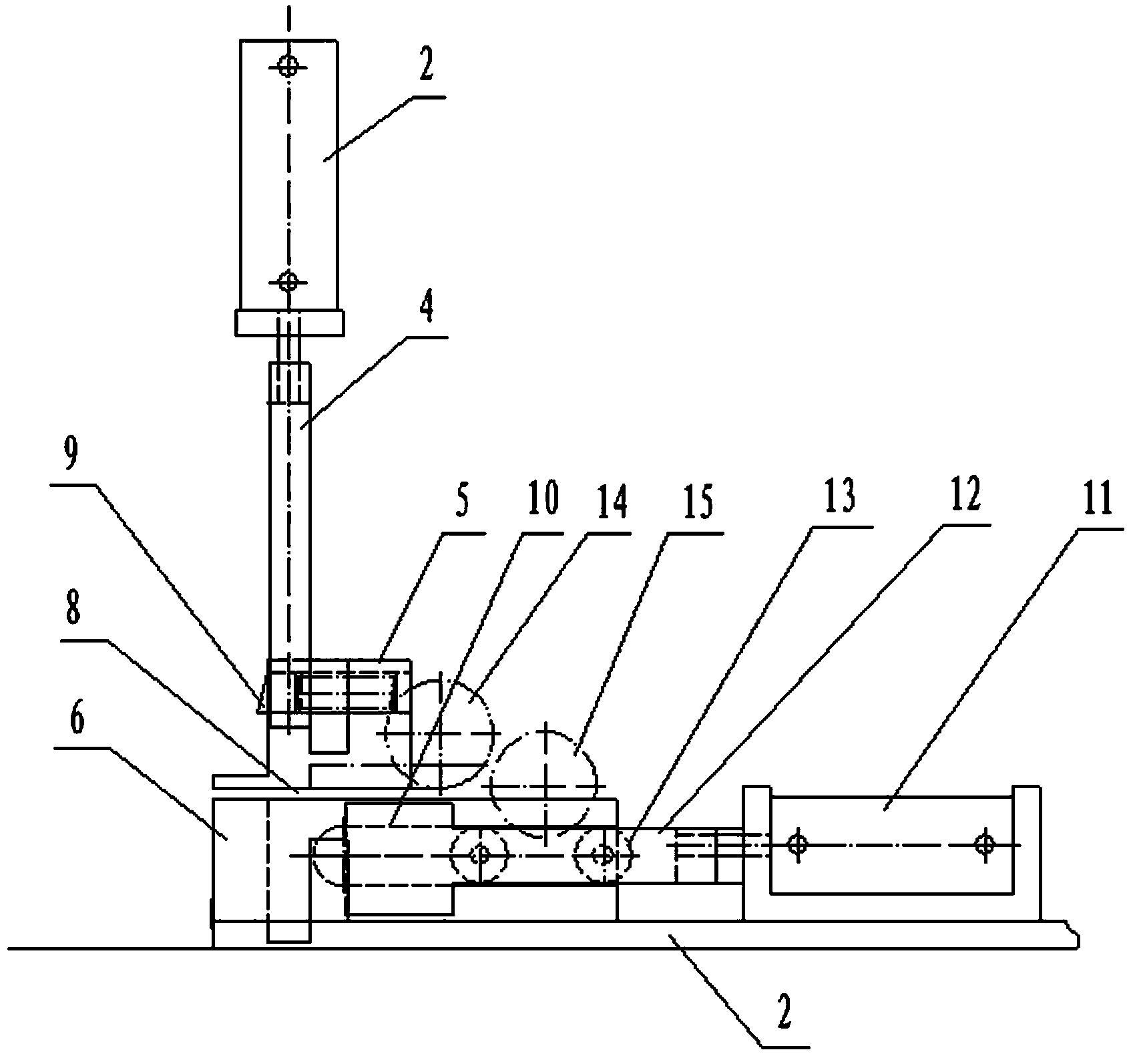

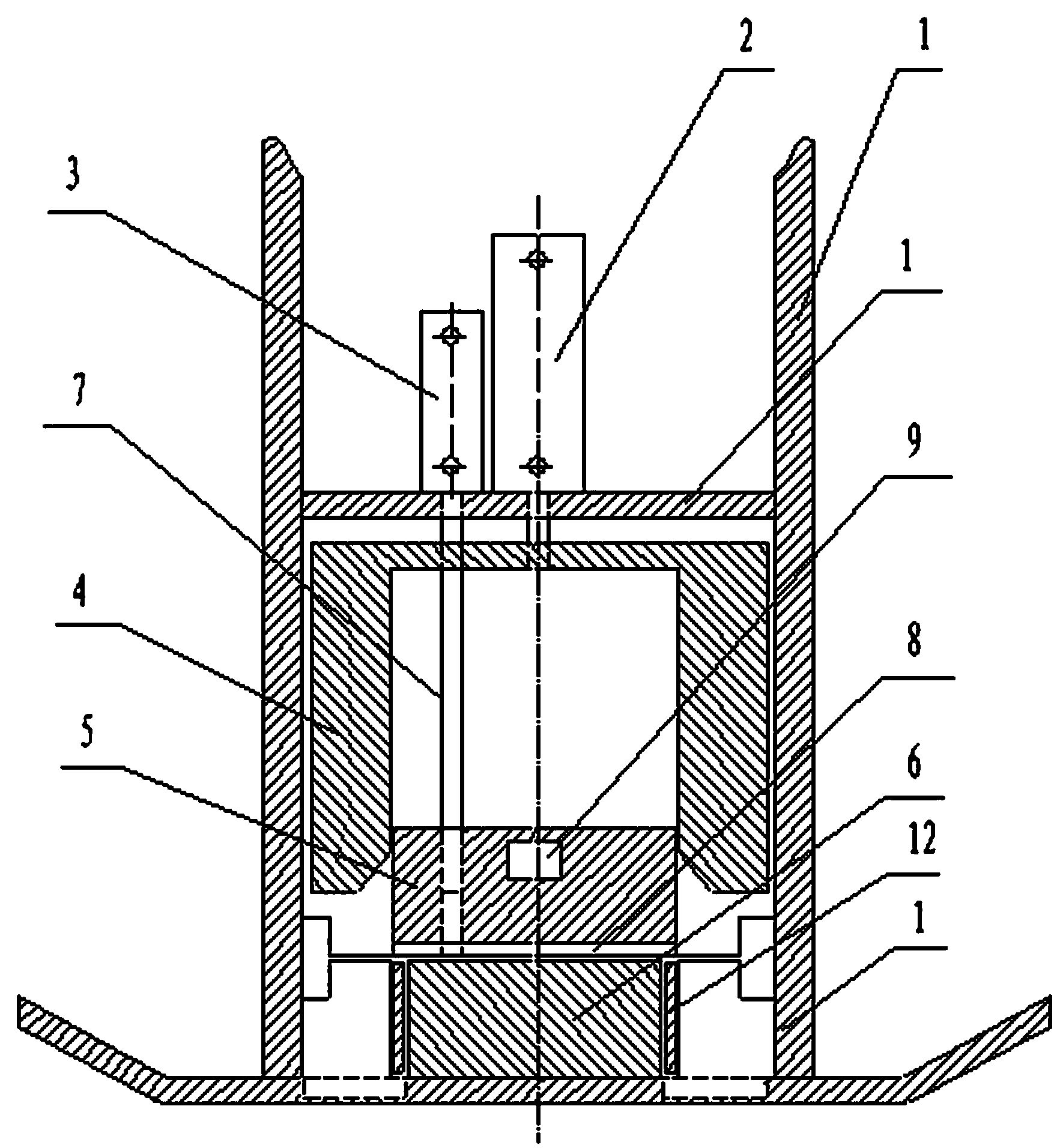

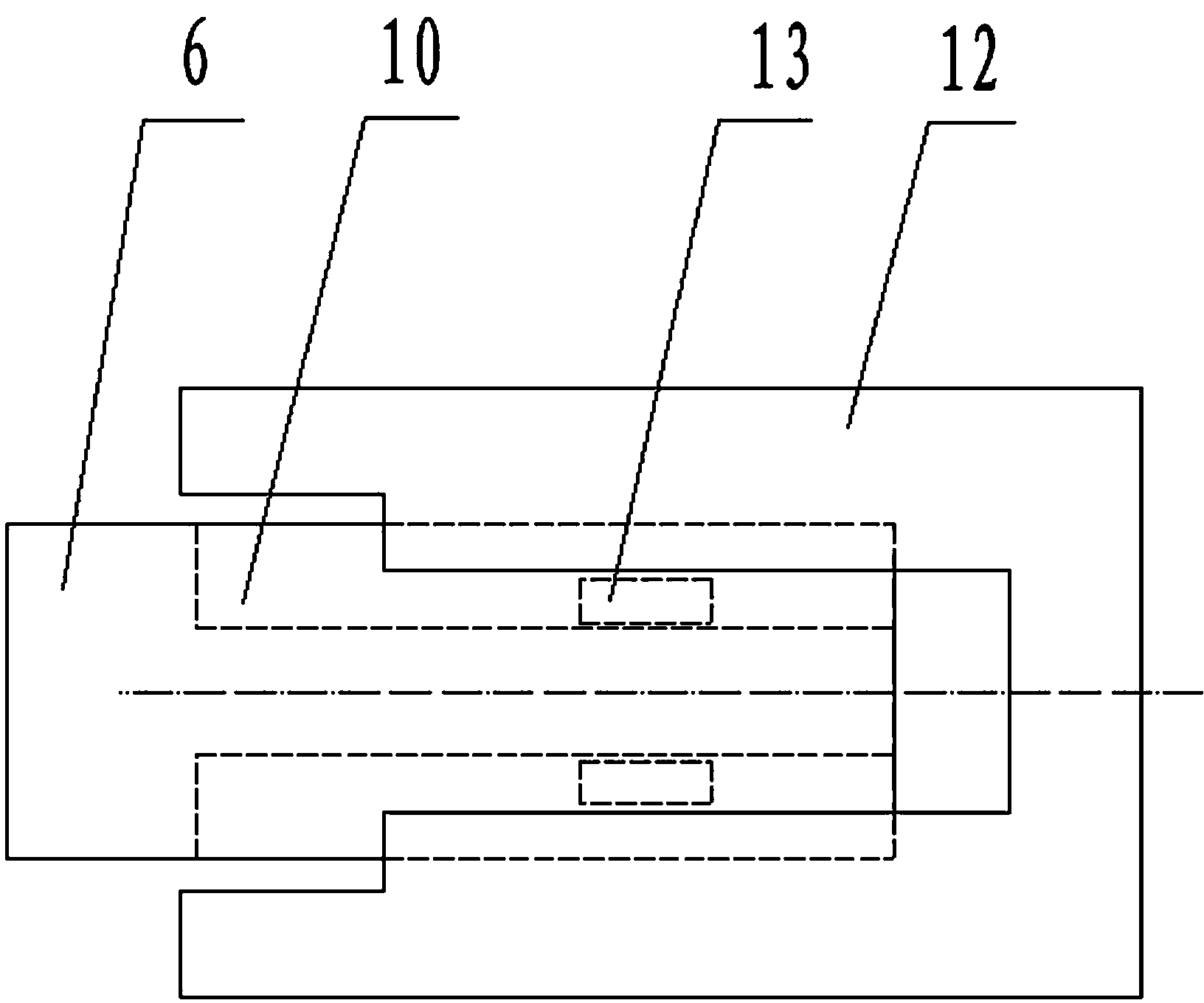

[0011] The plastic handle modification device of a fully automatic carton handle threading and buttoning machine according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0012] Depend on figure 1 , figure 2 , image 3 It can be seen that the plastic handle deforming device of a fully automatic carton handle threading and buttoning machine in this embodiment is composed of the frame 1, the deforming component and the pushing component. The deformation assembly of the present embodiment is composed of a deformation cylinder 2, a positioning cylinder 3, a deformed briquetting block 4 in the shape of "Π", an upper module 5, a lower module 6 and a positioning pin 7, and the deformed briquetting block 4 in the shape of "Π" is fixedly installed. On the cylinder shaft at the lower end of the deformation cylinder 2, the positioning pin 7 is fixed to the cylinder shaft at the lower end of the positioning cylinder 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com