On-machine automatic separation blanking device facing picker cold forging process

An automatic sorting and puncturing technology, which is applied in sorting and other directions, can solve problems such as efficiency and accuracy, and achieve the effects of ensuring consistency, improving detection accuracy, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

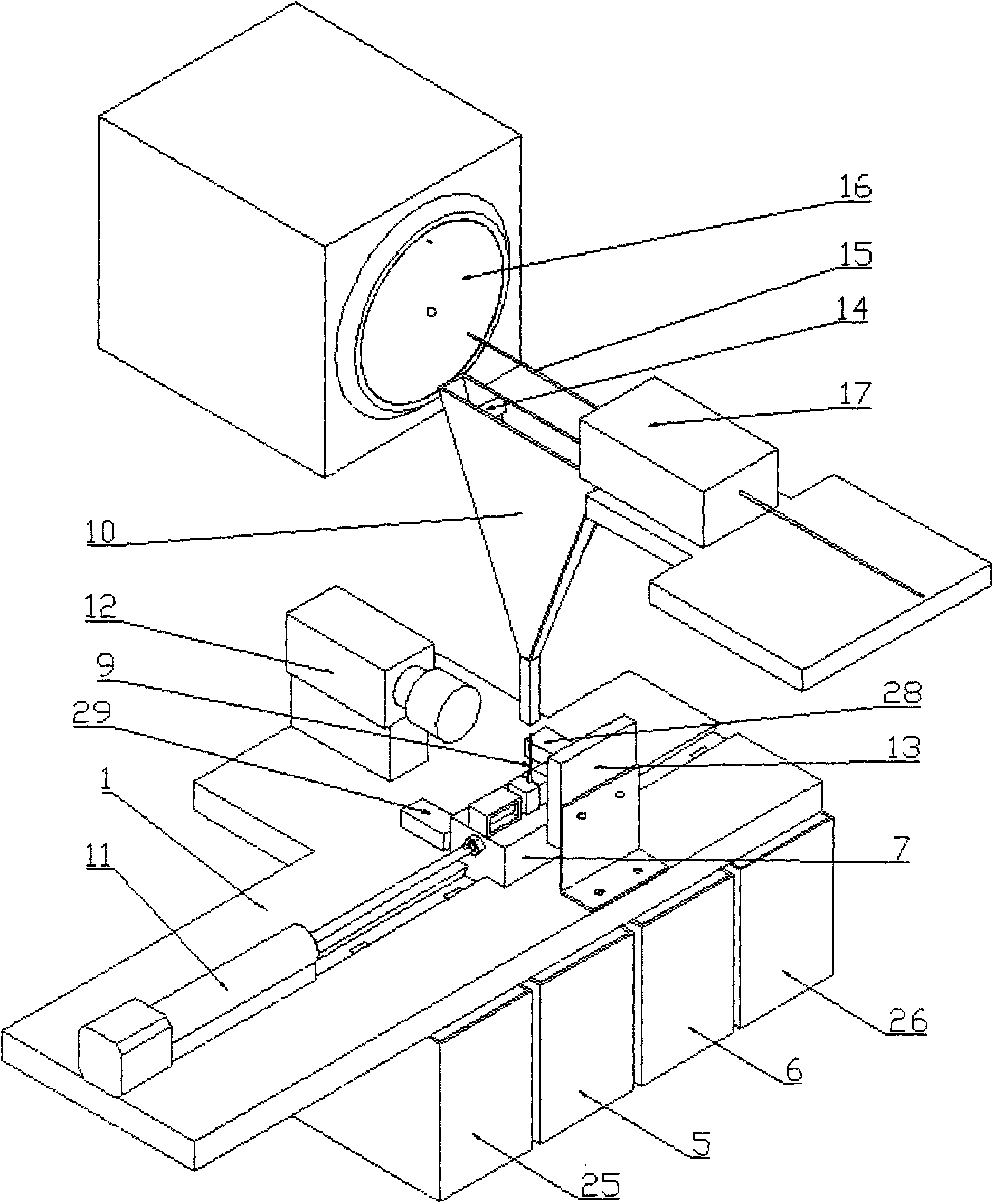

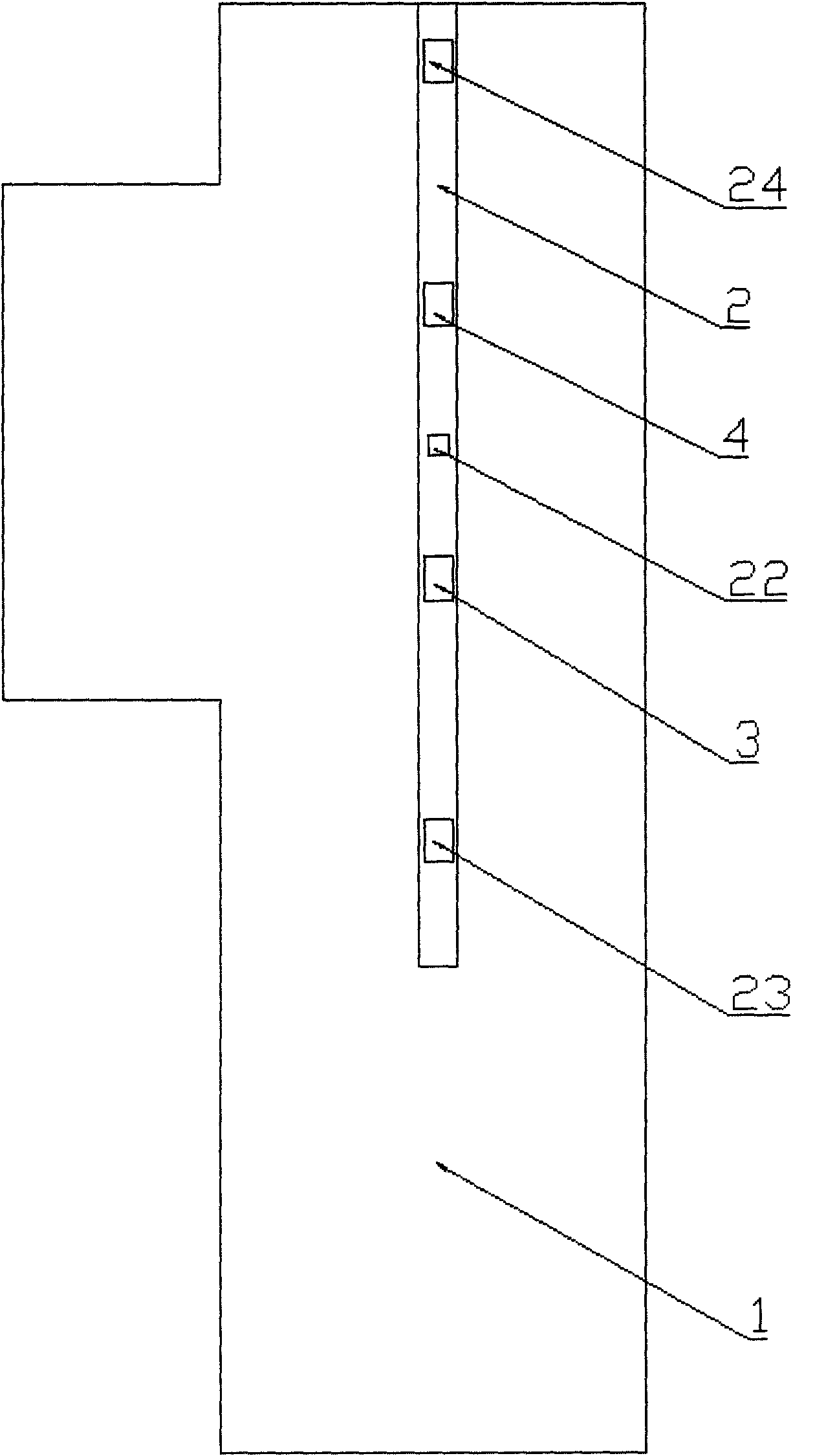

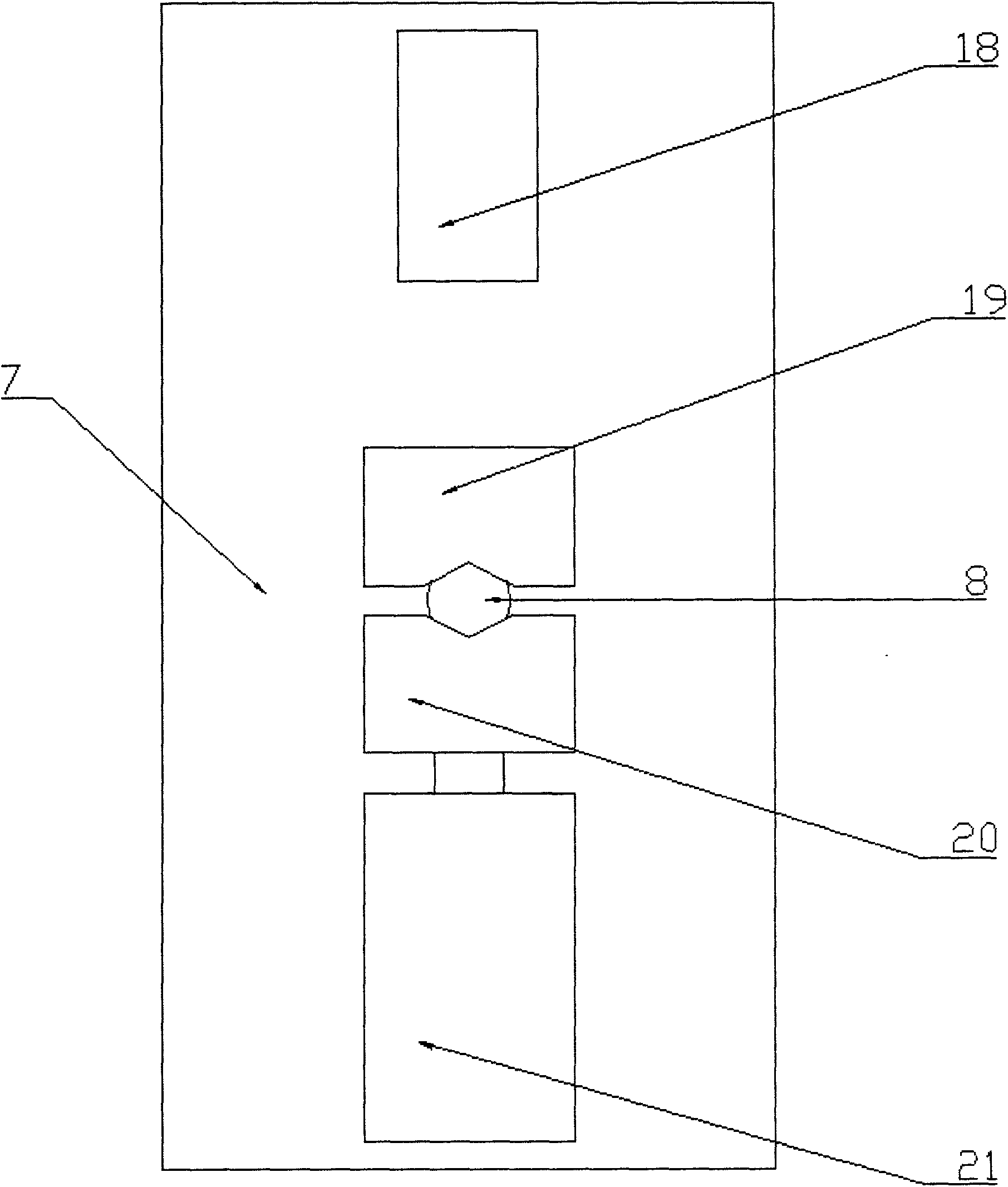

[0017] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, an on-machine automatic sorting and unloading device for the needle cold forging process, including a base 1, a large-size section receiving box 25, a medium-size section receiving box 5, a small-size section receiving box 6, and unqualified Material receiving box 26, dovetail groove 2, slider 7, hopper 10, electric push rod 11, CCD camera 12, machine vision light source 13, V-shaped blocks 19 and 20, electromagnet 21 and sensors 18, 28 and 29, the device Located between the rotary forging head 16 and the needle cutting mechanism 17, the hopper 10 is located directly below the needles 15 to be cut, the upper opening of the hopper 10 is rectangular, and its size is determined to be able to catch the needles 15 to be cut, and the bottom opening of the hopper 10 is circular , its d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com