Processing process of fresh preserved szechuan pickle

A processing technology and technology of mustard mustard, which is applied in the field of processing technology of Fuling mustard mustard, can solve problems such as excessive salt used in salt dehydration, mildew of raw materials, and soft taste of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

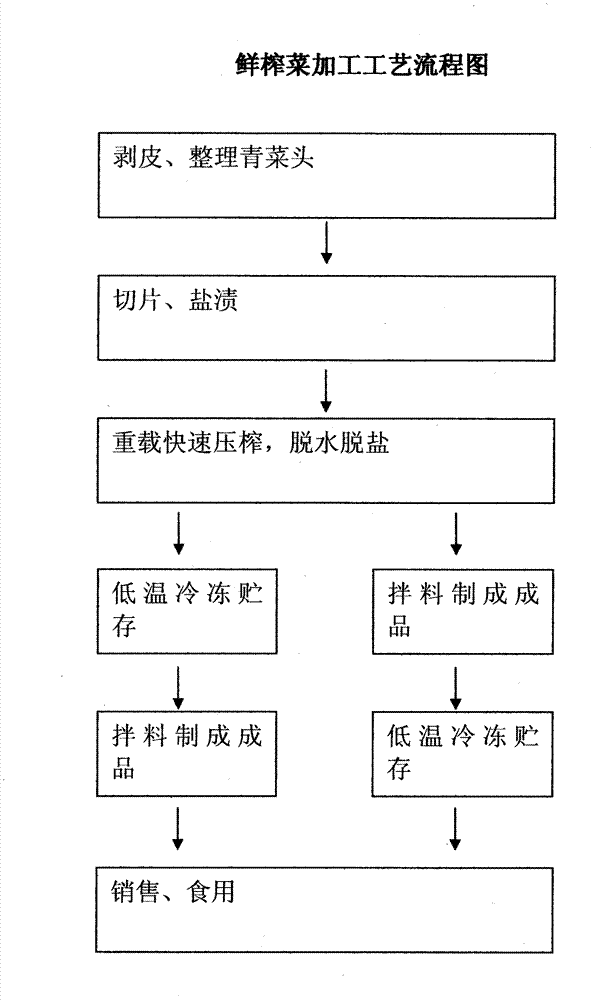

Image

Examples

Embodiment Construction

[0019] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0020] 1. Preliminary finishing: Peel and decontaminate the cabbage heads, wash and dry them;

[0021] 2. Slicing and salting: Cut 30 catties of green cabbage heads into thin slices of 2-3mm, add 1.5 catties of salt and mix well, soak for 2 hours;

[0022] 3. Quick pressing of heavy objects: put it in a leaky pocket, put 70 on top Press heavy objects such as stones about 100 catties for 60 hours, turn the raw materials once a day, and turn them twice in total. Thereafter, the raw material was taken out, and the water content of the raw material was less than 25%.

[0023] 3. Low-temperature frozen storage: The pressed and dehydrated raw materials are immediately packed into a low-temperature freezer, and the temperature is controlled below -17°C.

[0024] 4. Finished product: thaw the finished product after the above-mentioned "quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com