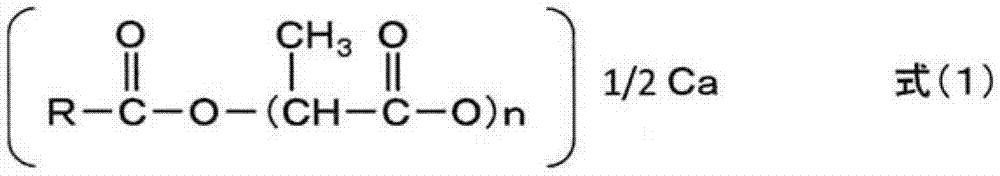

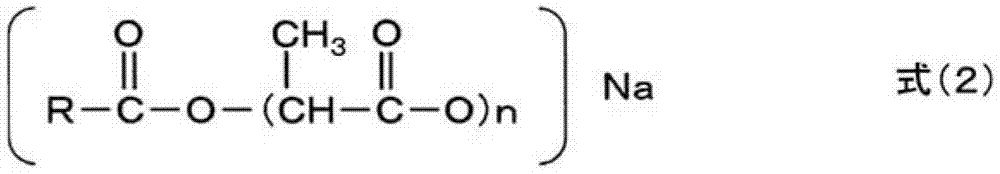

Grease composition

An oil composition and oil technology, applied in the production/processing of edible oil/fat, edible oil/fat phase, edible oil/fat, etc., can solve the problems of whitening of baked snacks, quality deterioration of compound snacks, softening of chocolate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0160] [Analytical method]

[0161] Composition of fatty acids:

[0162] Prepare fatty acid methyl esters according to the "Standard Fatty Acid Analysis Test Method" compiled by the Japanese Oil Chemists' Society (2.4.1.-1996), and pass the American Oil Chemists.Society Official Method Ce1f-96 (GLC method) to measure the samples obtained.

[0163] Triacylglycerol Composition:

[0164] Measured in accordance with the method described in 2.4.6.1 Triacylglycerol Composition (Gas Chromatography) described in Standard Oils and Fats Analysis Test Method.

[0165] [Preparation example 1] Preparation of transesterified oil

[0166] The oils and fats were mixed in the ratio (unit: mass %) described in Table 1 below, and reacted at 80° C. for 30 minutes using 0.1 mass % sodium methoxide relative to the mixed oils and fats as a catalyst to obtain random transesterified oil. The fats and oils were washed with water, decolorized and deodorized by usual methods to obtain fats and oils 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com