Frame sealing glue injector used for forming display frame body

一种封框胶、显示器的技术,应用在液体喷射装置、仪器、应用等方向,能够解决黏附性降低、成框效率低、没有处理过程等问题,达到缩短成框时间、涂布稳定顺畅、提高生产效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

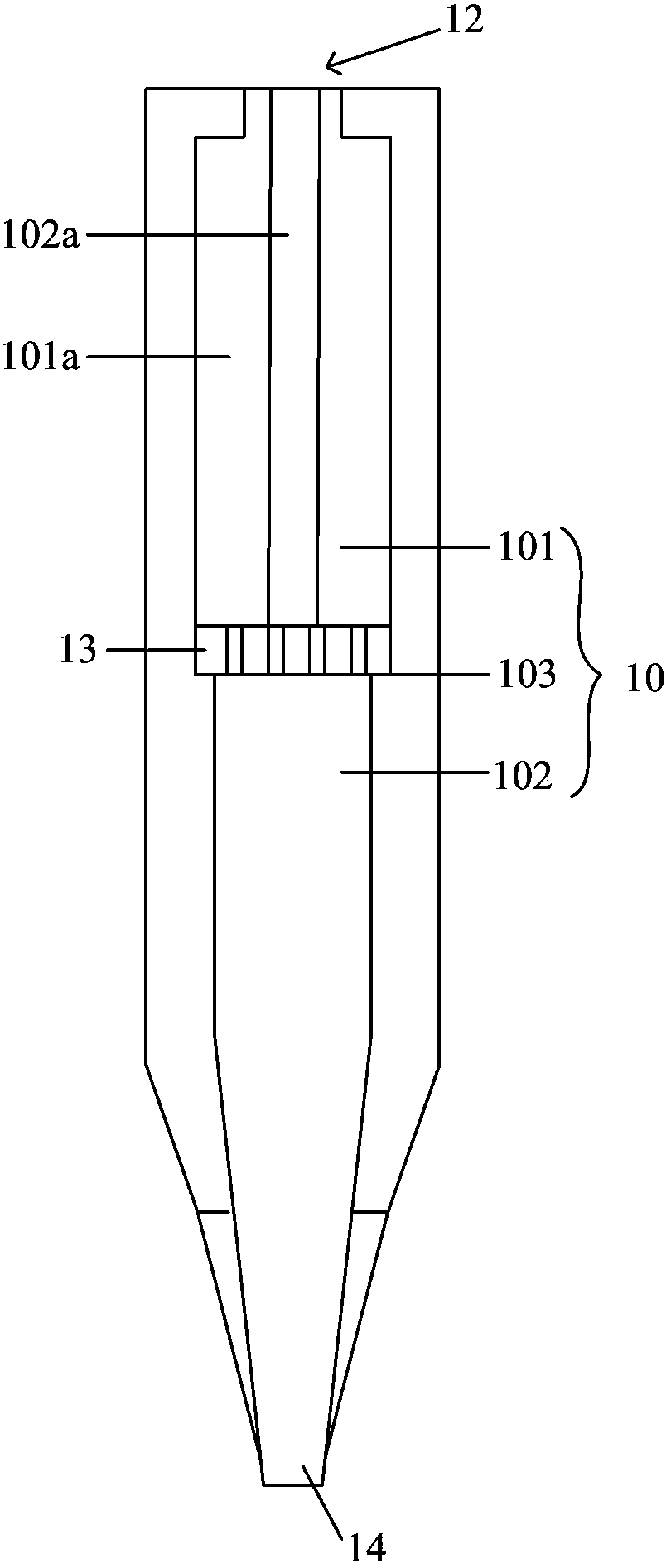

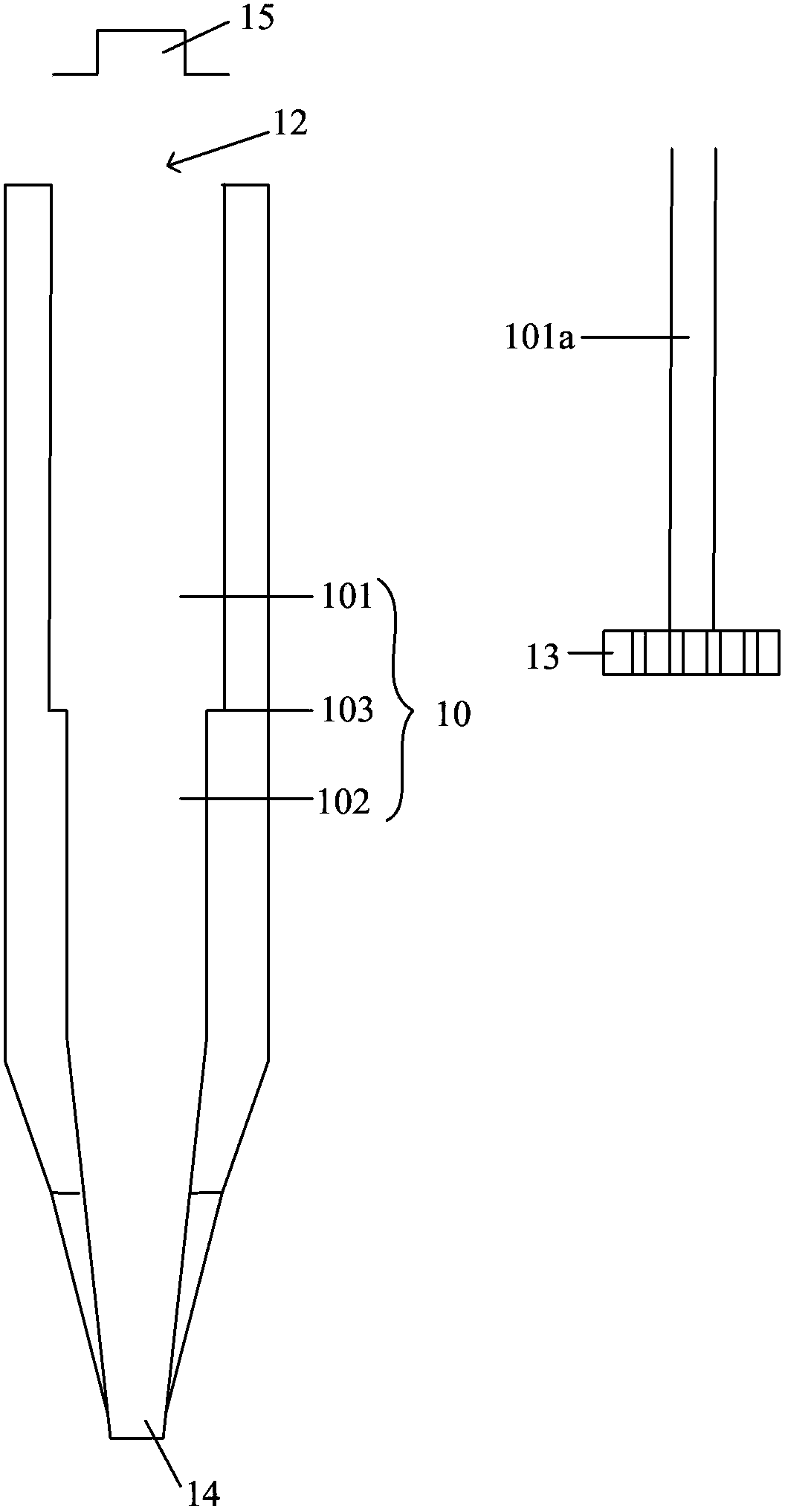

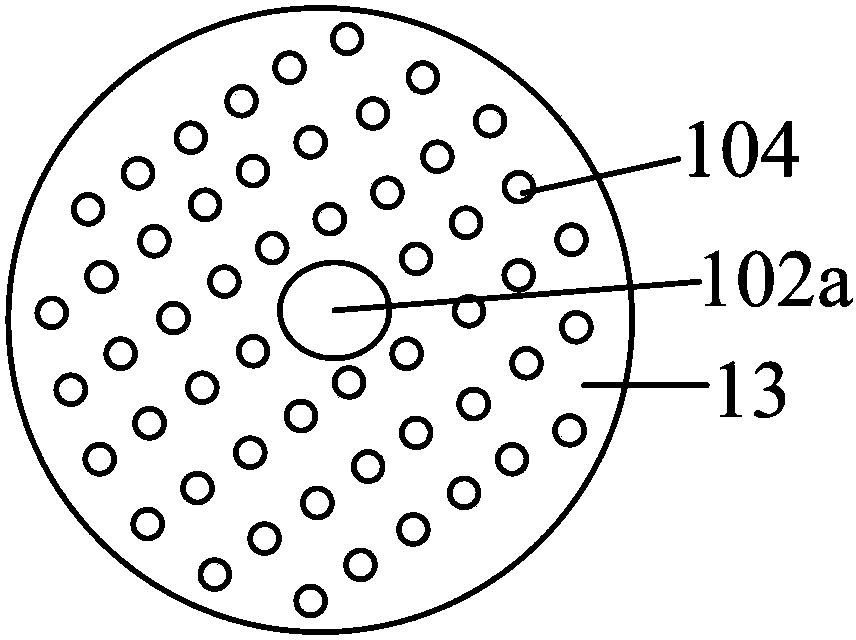

[0025] refer to figure 1 As shown, the present invention provides a frame sealing glue injector 100 for forming a display frame, which is provided with a cavity 10, the upper end of the cavity 10 is provided with an opening 12, the lower end is provided with a nozzle 14, and the upper end is open 12 is connected to high-pressure nitrogen gas, the sealant is filled in the cavity 10 and extruded through the lower nozzle 14, and a filter device 13 is built in the cavity 10 to block foreign matter inside the sealant.

[0026] The original cavity 10 penetrates up and down, and the sealant is filled therein. By introducing high-pressure nitrogen gas from the upper end opening 12, under the action of the air pressure of the high-pressure nitrogen, the sealant filled in it is extruded from the nozzle 14. The inner diameter of the outlet of the nozzle 14 is 150-500 microns. In order to extrude large particles of foreign matter in the frame sealant, the filter device 13 is built in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com