Thin-plate blanking device

A thin plate and adjusting device technology, applied in metal processing and other directions, can solve the problems of difficulty in mold manufacturing, large workpieces, burrs, etc., and achieve the effect of good punching effect and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

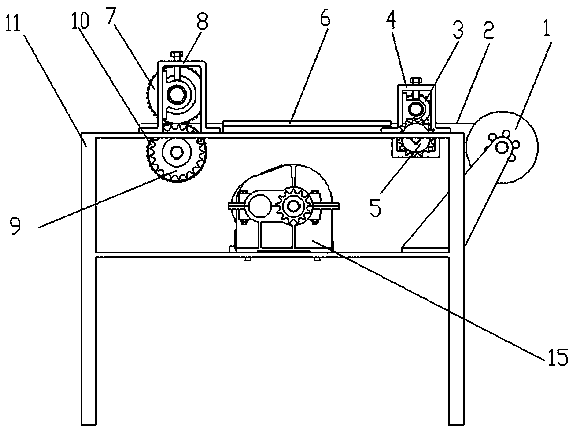

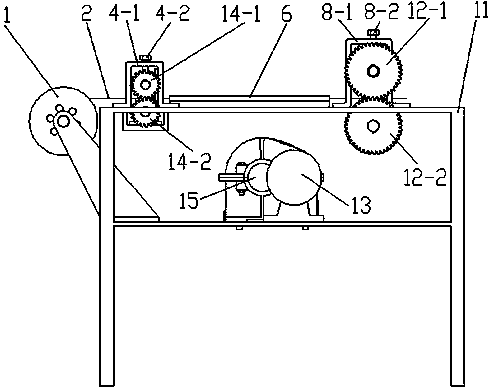

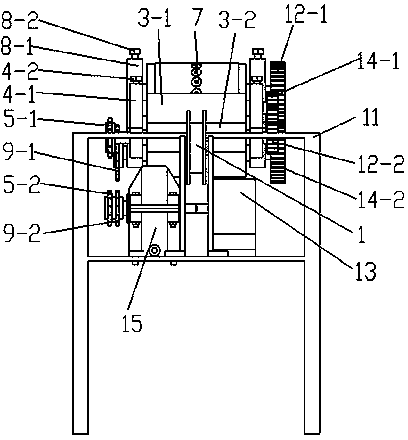

[0023] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a thin plate blanking device includes a material roller 1, a feeding roller 3, a first roller adjustment device 4, a first chain transmission device 5, a strip guide device 6, a convex and concave die roller 7, a second roller Adjusting device 8, the second chain transmission 9, die roller 10, frame 11, first gear transmission 14, motor 13, second gear transmission 12 and speed reducer 15, wherein, frame 11 has two The four-corner frame of the floor plate, the material roller 1 is fixed on the lower platen of the frame 11, the inlet end of the material roller 1 is flush with the upper platen of the frame 11, and the feeding roller 3 is fixed on the upper layer of the frame 11 The platen is located on the same side of the frame 11 as the material roller 1, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com