Milling device for foundry sand mould pouring gate

A technology of milling machine and foundry sand, which is applied in the direction of foundry molding equipment, molds, mold components, etc., which can solve the problems of easy gas entrapment, molten iron overflow, casting pores and slag holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

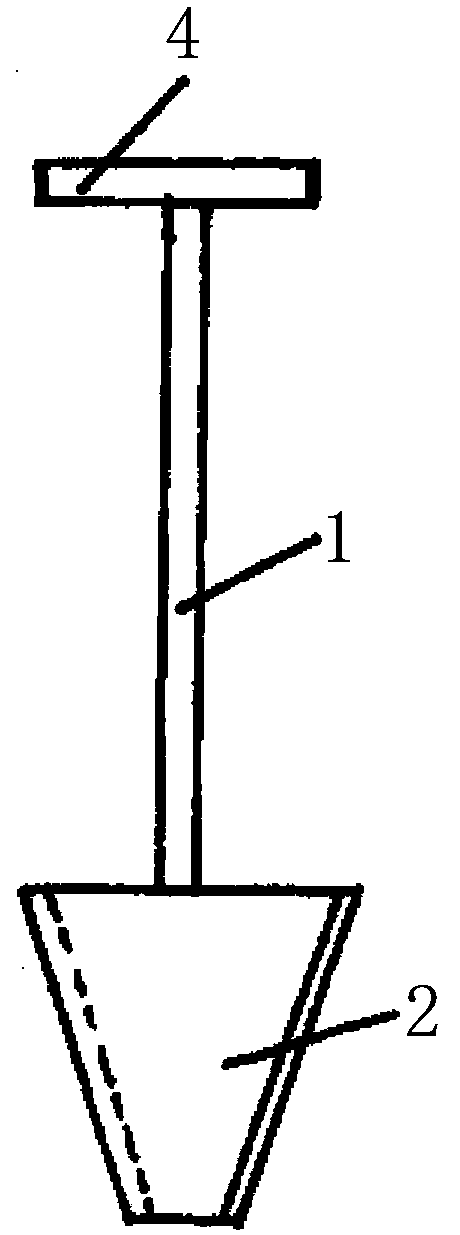

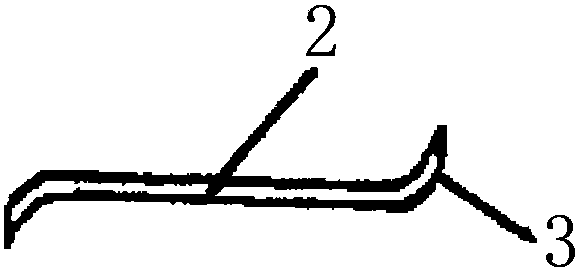

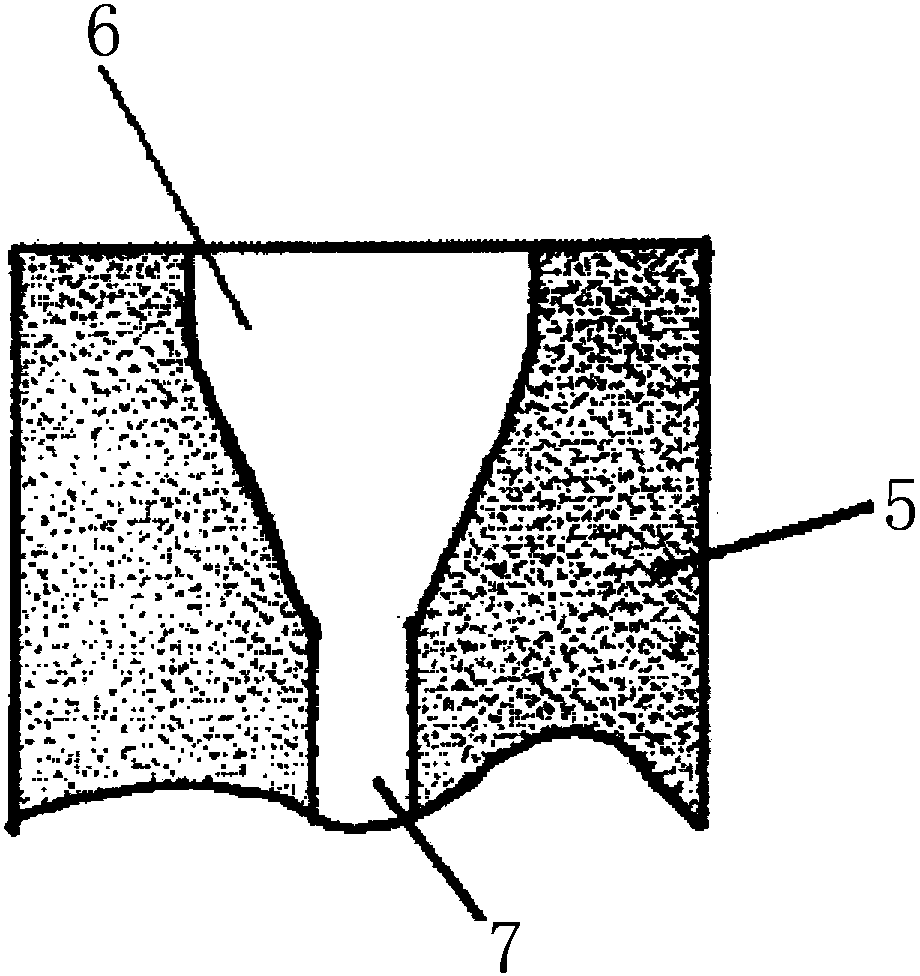

[0011] Such as figure 1 , 2 , Shown in 3, the present invention is connected with trapezoidal shovel head 2 at the lower end of handle 1, is respectively provided with curved milling cutter 3 on the both sides of shovel head 2, and rotation handle 4 is located at the upper end of handle 1. Through the above settings, the trapezoidal shovel 2 of the present invention is inserted into the casting sand mold 5, and the trapezoidal shovel 2 is driven to rotate by rotating the handle 4, and the curved milling cutters 3 on both sides of the trapezoidal shovel 2 connect the gate cup 6 with the direct pouring The floating sand on the inner wall of the channel 7 is cleaned, so that the interior of the sprue cup 6 and the sprue 7 is smoothly transitioned, and when the molten metal is poured into the sprue cup 6, the molten metal can enter the mold through the sprue 7 smoothly, avoiding Turbulent flow and flushing of the mold, no gas is involved during pouring, and the yield of castings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com