Method for detecting crack defect of in-service strut porcelain insulator

A pillar porcelain insulator and defect technology, which is used in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of high instrument cost, observation angle problems, and detection of pillar porcelain insulator defects, etc., to achieve equipment operation safety, reduce Inventory and the effect of improving maintenance levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

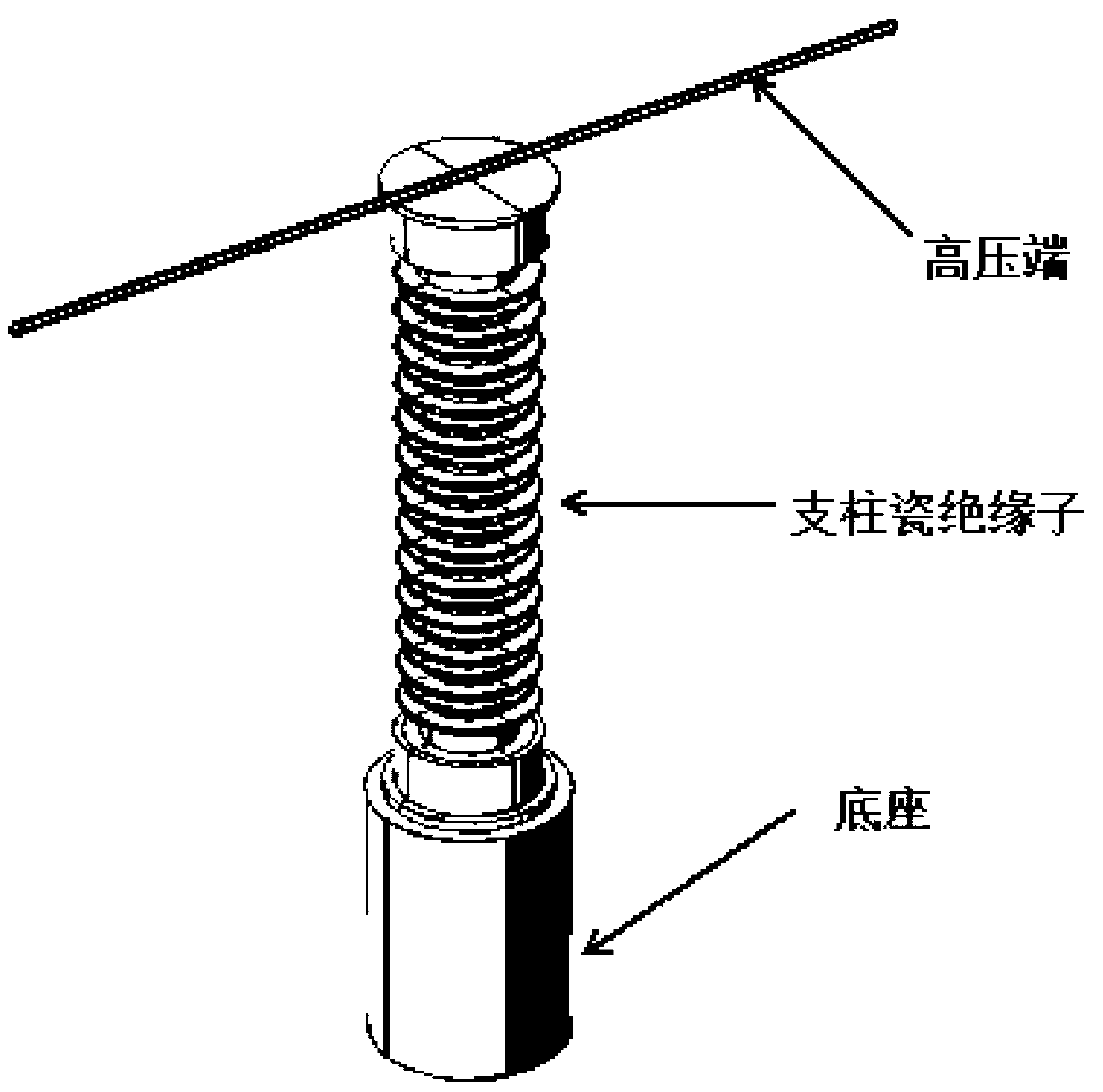

[0054] A method for detecting crack defects of porcelain insulators in service pillars. A pressure equalizing ring is fixed at one end of the measurement area close to the surface of the insulating pillar, and a horizontal circle surrounding the insulating pillar is equipotential and used as a reference potential. This method uses the principle of electric field method to detect the surface crack defects of high-voltage pillar porcelain insulators. In this case, the 110kV pillar porcelain insulators supporting the high-voltage busbar in the substation are tested, mainly on the surface of the porcelain pillar between the lower flange and the first umbrella skirt. Detection. The method steps are as follows:

[0055] (1) According to the size of the component under test, the number of measurement points of the 110kV pillar porcelain insulator, that is, the number of probes is 16; the resistance divider rod device is selected for potential measurement.

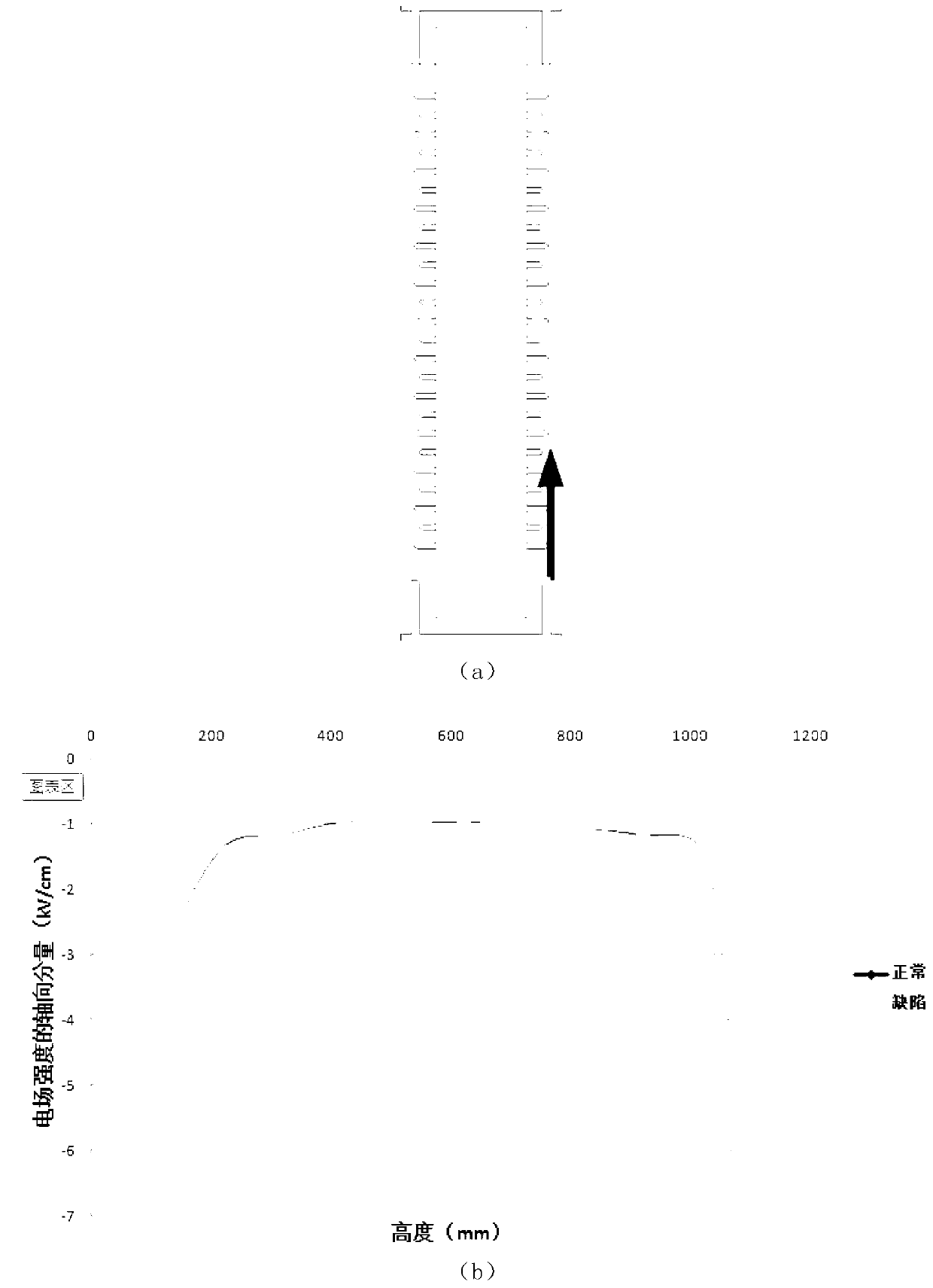

[0056] (2) 16 probes are measu...

Embodiment 2

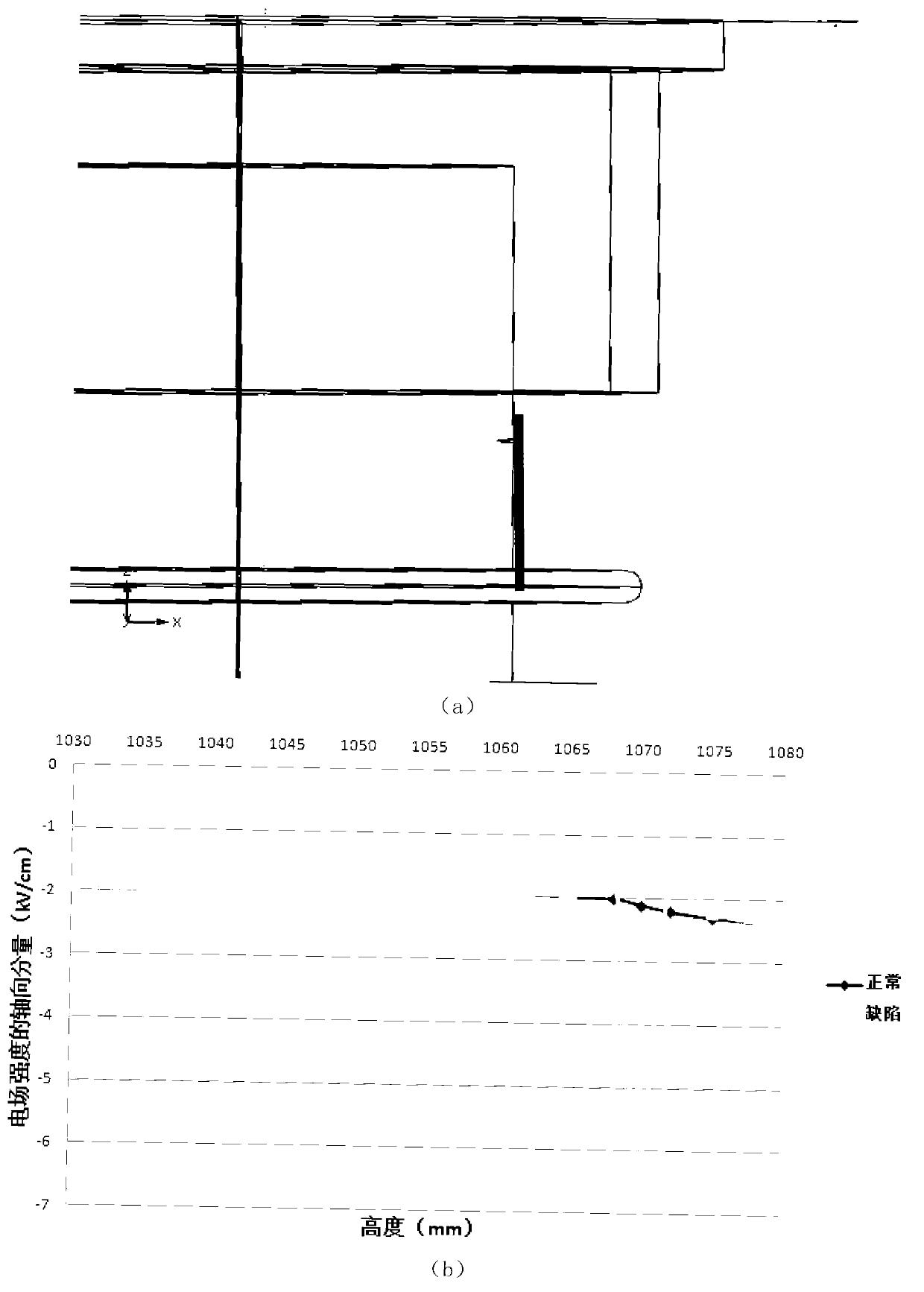

[0060] A method for detecting crack defects of porcelain insulators of in-service pillars. This method fixes a pressure equalizing ring at one end of the measurement area close to the surface of the insulating pillar, and equipotentializes a horizontal circle around the insulating pillar as a reference potential. This method uses the principle of electric field method to detect the surface crack defects of high-voltage pillar porcelain insulators. In this case, the 110kV pillar porcelain insulators supporting the high-voltage busbar in the substation are tested, mainly on the surface of the porcelain pillar between the lower flange and the first umbrella skirt. Detection. The detection steps are as shown in Example 1, and finally the electric field distribution curve is drawn as Picture 10 As shown, Picture 10 It is a schematic diagram of the data of Example 2, which is also represented by two curves. It is judged that the distortion rate of the electric field at a distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com