Production method of oil removal agent for stainless steel

A production method and degreasing agent technology, applied in the field of degreasing agent production, can solve the problems of increased labor costs, inconvenient factory production, and increased degreasing time, so as to save labor costs, simple production method, and degreasing The effect of oil capacity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

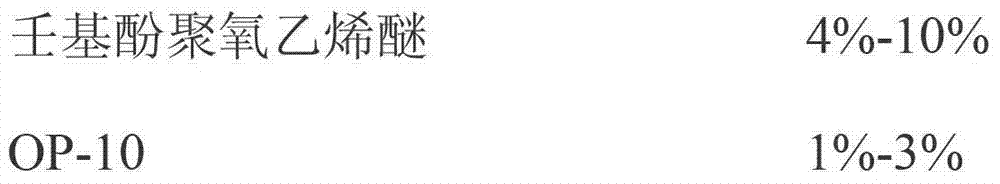

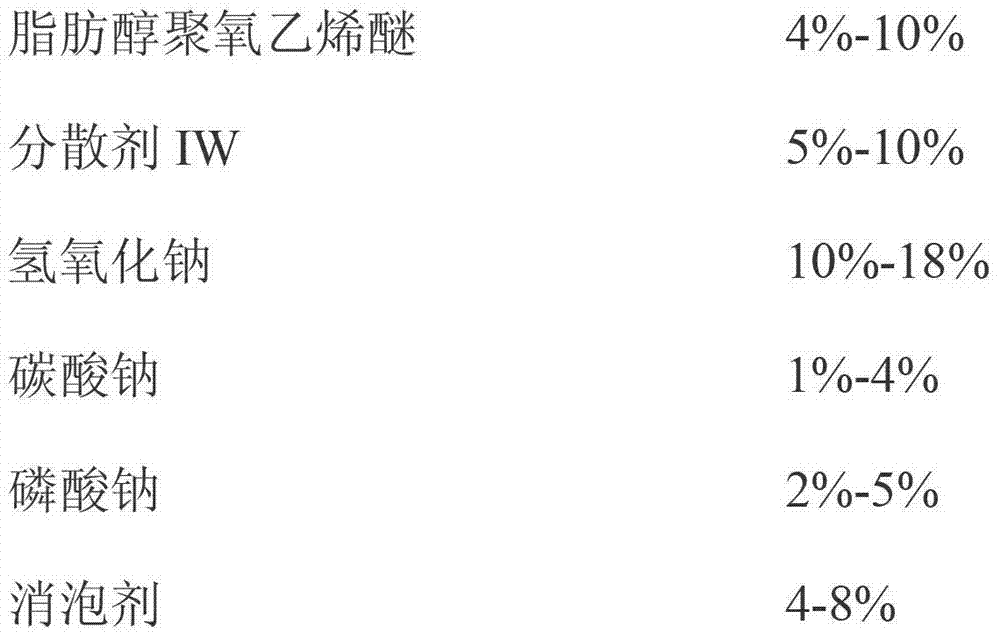

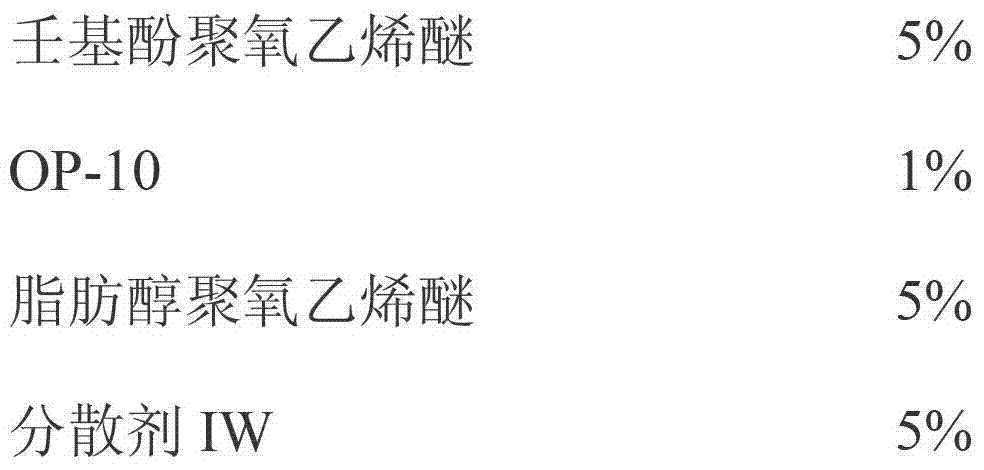

[0028] Prepare the present invention's degreaser for stainless steel respectively by following formula:

[0029] Table 1 embodiment 1-4 is used for the formula (unit: weight percent) of the degreasing agent of stainless steel

[0030]

[0031] The preparation method of embodiment 1-4 is similar, taking embodiment 3 as example, its preparation method is:

[0032] (1) Add 500L of water to a 1000L reaction stirring tank, then add sodium hydroxide, and stir for 10 minutes;

[0033] (2) Add TX-10 into the reaction stirring tank, and stir with sodium hydroxide aqueous solution for 30 minutes;

[0034] (3) Add OP-10, AEO-9 and dispersant IW in sequence, and stir for 60 minutes;

[0035] (4) Add sodium carbonate and sodium phosphate into the reaction stirring tank, and stir until there is no sediment in the tank;

[0036] (5) Add defoamer FAG470, stir for 30 minutes, then add water to 1000L liquid level.

Embodiment 5

[0038] Take flat 201 stainless steel plate workpieces of the same size, spray and clean them with the degreaser prepared in Examples 1-4 and the commercially available degreaser respectively, and compare the degreasing effect:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com