Steel member splicing pretensioner and method for connecting component elements with pretensioner

A technology of pretensioners and steel components, applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., to achieve the effects of convenient operation, easy disassembly and assembly, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

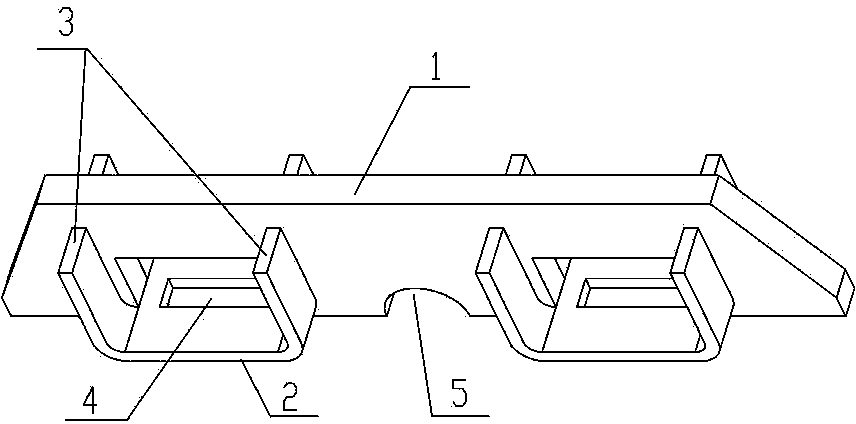

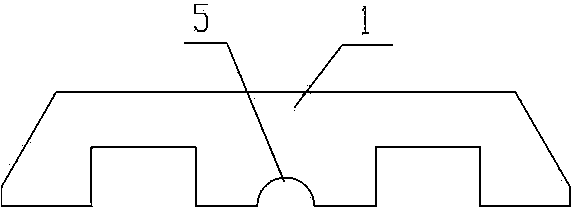

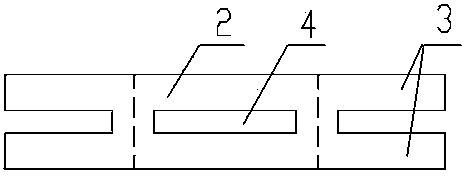

[0025] Such as figure 1 , 2 , 3, the splicing pretensioner for steel members according to the present invention includes trapezoidal plate-shaped keels 1 with rectangular arch grooves at intervals arranged vertically below, horizontally clamped between the rectangular arch grooves of the plate-shaped keels 1 The fixed plate 2, the lower bottom surface of the fixed plate 2 and the plate-shaped keel 1 are located on the same plane; the two pairs of supporting side plates 3 extending upward from the sides of the fixed plate 2 along the plate-shaped keel 1 are respectively connected to the two sides of the plate-shaped keel 1. The side is fixedly connected (welded), and a rectangular through hole is formed between the upper surface of the fixed plate, the two sides of the rectangular arch groove and the top surface; a fixed through groove 4 is opened on the fixed plate corresponding to the position of the rectangular through hole, and the plate-shaped keel 1. A semicircular notch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com