Cylinder bore machining method

A processing method and cylinder hole technology, applied in the field of cylinder hole processing, can solve the problems of poor lubrication and anti-friction effect, wear, affecting the performance and life of the engine, etc., so as to improve tribological performance, enhance wear resistance and reduce oil consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

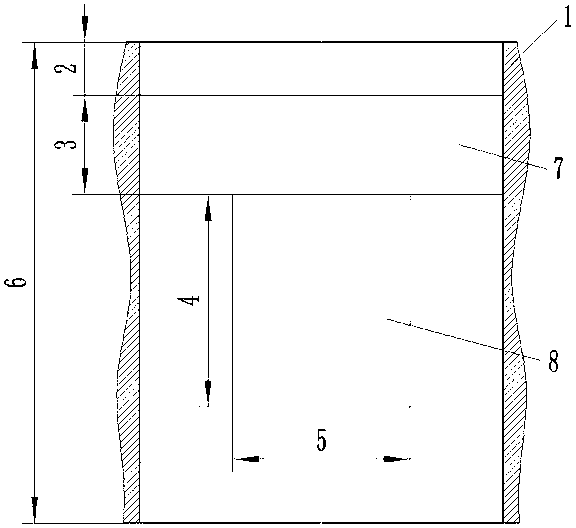

[0015] figure 1 It is a schematic diagram of cutting and flattening the cylinder bore 1. After the cylinder bore 1 is cut, it is divided into two parts, and the texture areas on the two parts are the same.

[0016] The pretreatment is obtained by mechanical honing process, and the surface morphology parameters after pretreatment are required: Rpk≤0.1μm, Rk≤0.15μm, Rvk≤0.3μm, Mr185%.

[0017] Surface texturing in the cylinder bore 1, the target area is the top dead center zone 7 and the piston skirt friction zone 8, the top dead center zone 7 covers the top dead center of the cylinder bore 1, and the piston skirt friction zone 8 covers the cylinder The contact area between the hole 1 and the piston during relative motion; the surface texture parameters of the above two areas are different, the cavity diameter, cavity dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com