Method for fixing microphone shell and circuit board

A circuit board and microphone technology, applied in the field of microphones, can solve problems such as cumbersome operation, unstable fixing, and deflected edge banding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

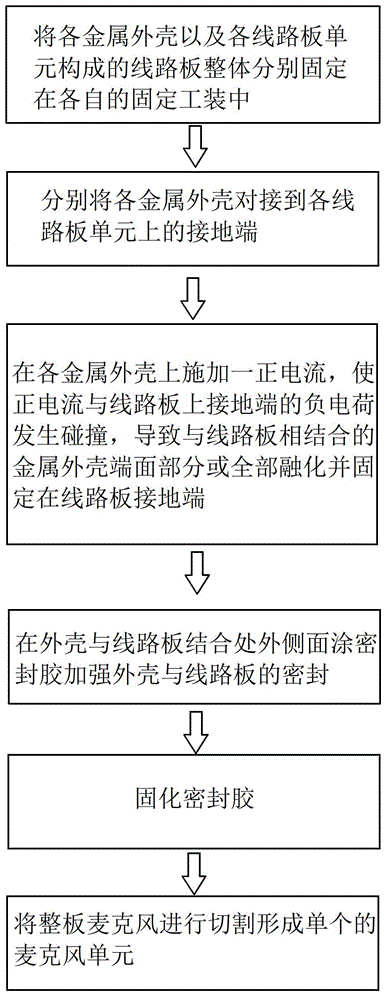

[0022] Such as figure 1 As shown, the method for fixing the microphone shell and the circuit board of the present invention includes the following steps: Step 1: Fix the metal shell and the circuit board in respective fixing tools. Step 2: Butt the metal shell to the ground terminal of the circuit board; Step 3: Apply a positive current with a current range of 1-100A on the metal shell, so that the positive current and the negative charge of the ground terminal on the circuit board are generated The collision will cause the end face of the metal shell combined with the circuit board to partially or completely melt and be fixed on the ground terminal of the circuit board; the fourth step: apply sealant on the outer surface of the joint between the shell and the circuit board to strengthen the seal between the shell and the circuit board; Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com