Solenoid valve fault diagnostic method based on current detection

A fault diagnosis and current detection technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of changing the rigidity of the hydraulic system and not having intelligent identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

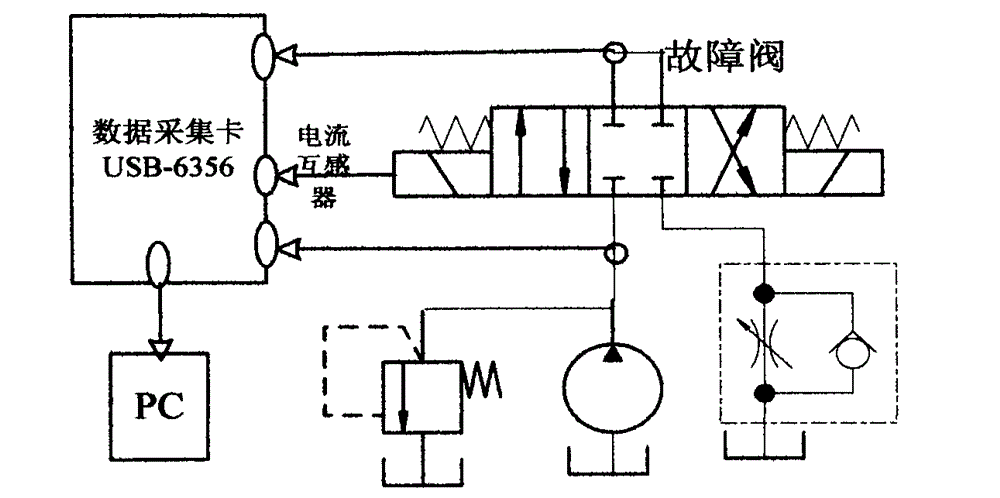

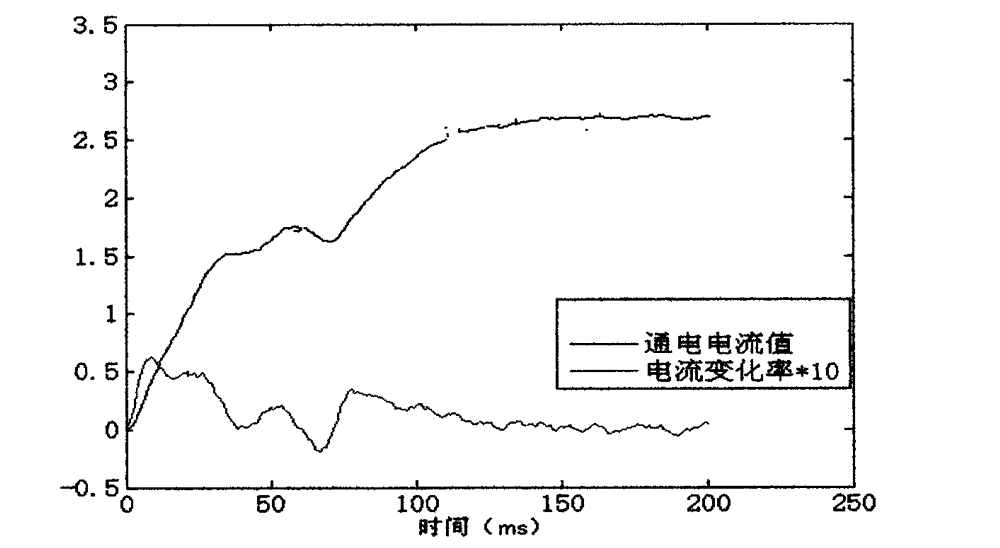

[0031] Now in conjunction with accompanying drawing, the specific embodiment of the present invention is set forth as follows:

Embodiment

[0033] Step 1: Set the faults of spool stuck, spring broken and spool unable to reset

[0034] Step 1.1: The spring at one end of the solenoid valve is broken. The method is to take out the spring between the plunger and the valve core at one end of the solenoid valve. When the electromagnetic coil at the other end is energized, the direction can be reversed reliably, but when it is disconnected, due to the lack of spring force for the spool to restore the neutral function, the spool is still in the working position, so the energized state simulates the fault when the spring breaks, and in the working position Power on can simulate the fault that the spool cannot be reset normally;

[0035] Step 1.2: One end of the solenoid valve is completely stuck. The method is to take out the spring between the ejector rod at one end of the solenoid valve and the valve core, and replace it with multiple pieces of hard paper. When the coil is energized, the solenoid valve is still in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com