An elastic foil gas bearing with bolted and adjusted preload

An elastic foil and gas bearing technology, which is applied to shafts and bearings, rotating bearings, bearings, etc., can solve the problems of failure, elastic foil gas bearing wear, elastic foil gas bearing failure, etc., and achieves low cost, The effect of high precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

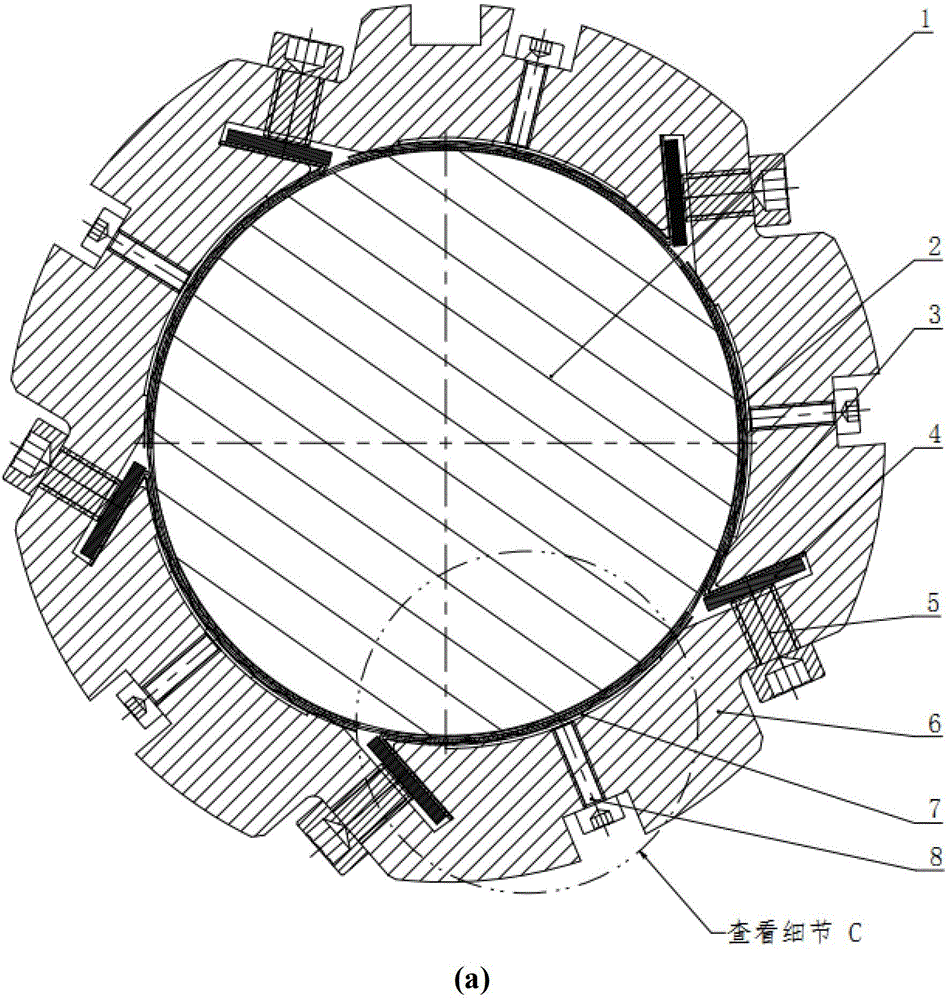

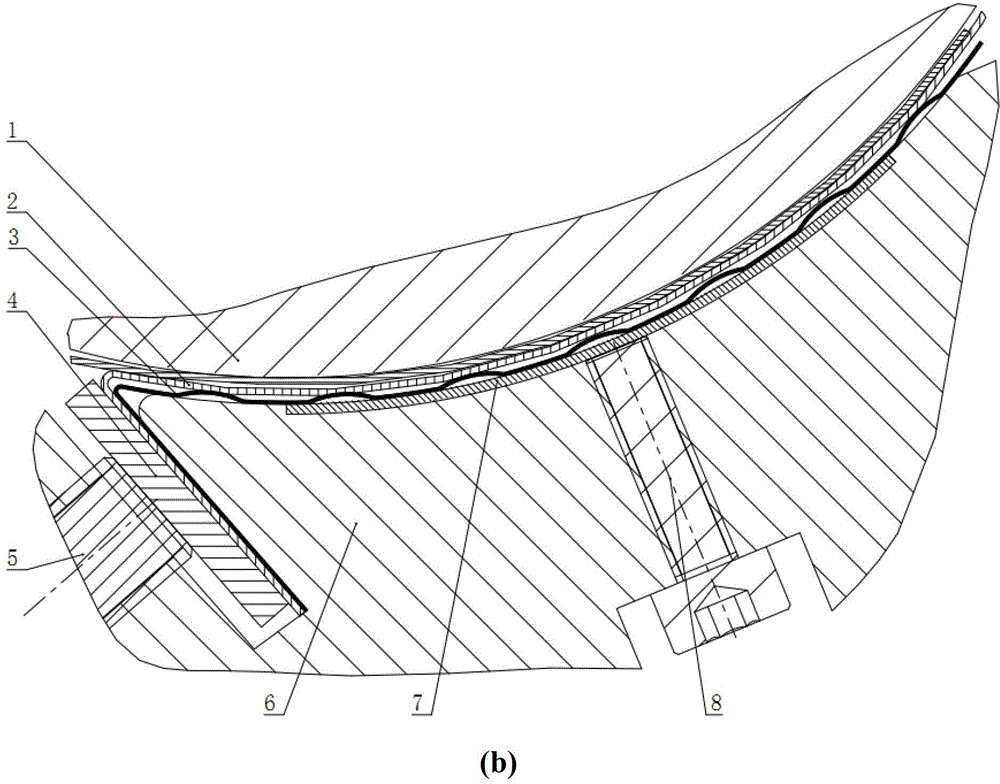

[0028] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] see figure 1 , 2 , 3, 4, 5, 6 and 7, an elastic foil gas bearing fixed by bolts and adjusted for preload, including a shaft 1, and the second curved surface 14 of the periodically uniformly distributed top layer foil 2 is attached to the shaft 1 On the journal 9, the arch foil 19 of the bottom arch foil 3 is supported under the first curved surface 12 of the top layer foil 2, and the first arc surface 18 of the bottom arch foil 3 is attached to the second arc surface of the bearing seat 6 28 and the third arc surface 34 of the second gasket 7, the first plane 10 of the fixed top layer foil 2 and the second plane 16 of the bottom arch foil 3 are sequentially pasted on the first gasket 4, the first chamfer 11 of the fixed top layer foil 2, the second chamfer 17 of the bottom arch foil 3 and the third ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com