Compound type cooling system for engine and vehicle using same

A cooling system and engine technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve problems such as the engine cannot dissipate heat normally, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Such as figure 1 As shown, the compound cooling system for the engine in this embodiment includes a radiator for providing coolant for the engine, a circulation line 11 for delivering the coolant, an intercooler for cooling the output gas of the engine supercharger, and Pipeline 12 for conveying gas. An electronically controlled clutch fan 13 is arranged at the radiator to cool down the coolant in the radiator. The electronically controlled clutch fan 13 adopts a clutch with multi-stage speed change. The power of the electronically controlled clutch fan is provided by the engine of the vehicle. A water temperature sensor 14 is provided on the pipeline section for delivering the coolant heated by the engine to the radiator. A motor fan 15 is arranged at the intercooler to cool down the high-temperature gas in the intercooler. The power of the motor fan is provided by the battery of the vehicle, and the gas delivery pipeline 12 is a pipe for delivering high-temperature g...

Embodiment 2

[0024] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is that the water temperature sensor 24 is arranged on the pipeline section that delivers coolant from the radiator to the engine, and the air temperature sensor 26 is installed on the pipeline section that delivers low-temperature gas from the intercooler to the engine. .

[0025] The overall control method of the cooling system is the same, only that the action value of the logic controller setting stage needs to be adjusted accordingly.

Embodiment 3

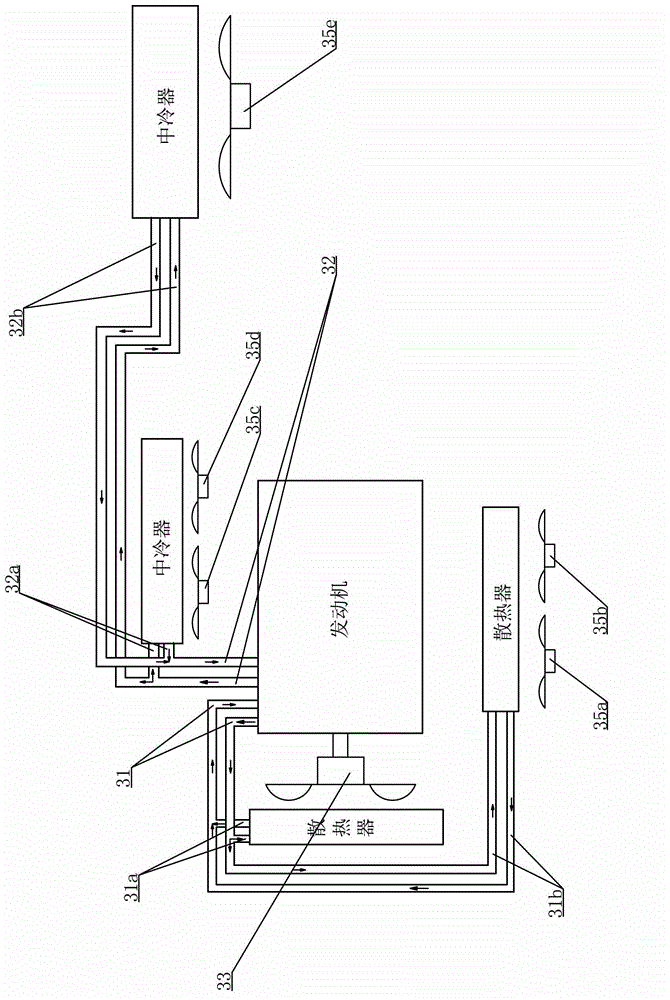

[0027] Such as image 3 As shown, the difference between this embodiment and Embodiments 1 and 2 is that there are two radiators that provide coolant for the engine, and the branch circulation pipelines 31a, 31b of the two radiators that deliver coolant are connected in parallel to deliver coolant to the engine. The circulation pipeline 31 of the coolant communicates, and an electronically controlled clutch fan 33 is arranged at one of the radiators, and an electric fan 35a, 35b is arranged at the other radiator, and the intercooler that provides cooling for the output gas of the engine supercharger is provided with two One, the branch pipes 32a, 32b for conveying gas of the two intercoolers are connected together to communicate with the pipeline 32 for conveying gas to the engine, and electric fans 35c, 35d, 35e are respectively arranged at the two intercoolers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com