Clutch braking device, winding machine comprising device and operation method of winding machine

A technology of braking device and hoist, which is applied in the direction of brake actuator, combination of coupling and brake, clutch, etc., can solve the problems of complex system, high failure rate of pressure reducing valve, increased failure rate of hoist, etc. Production cost, improved safety, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

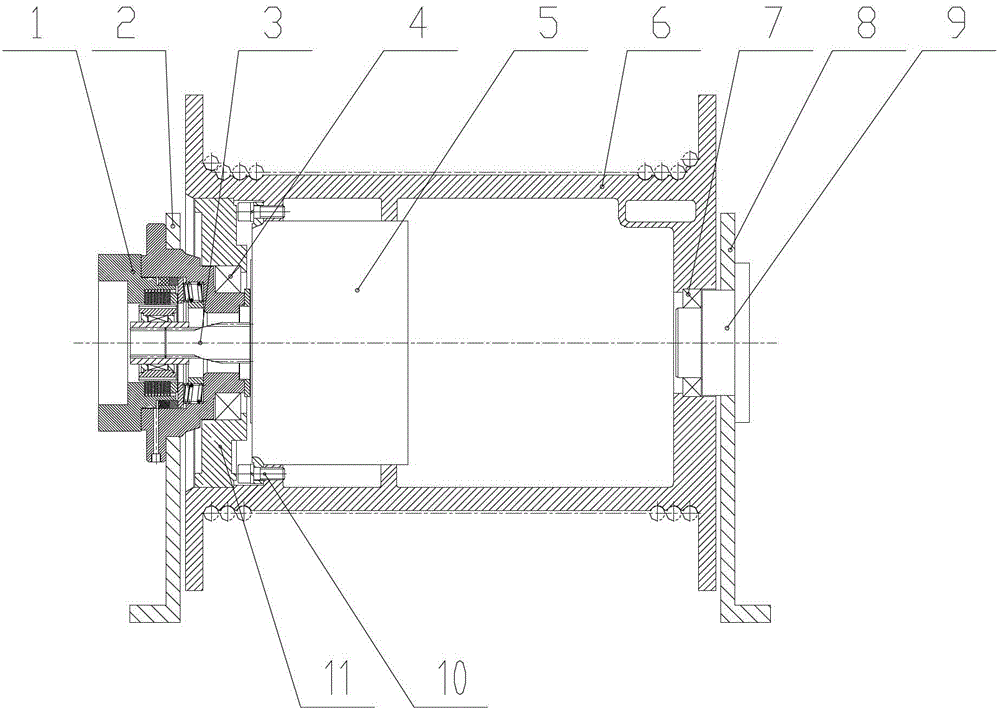

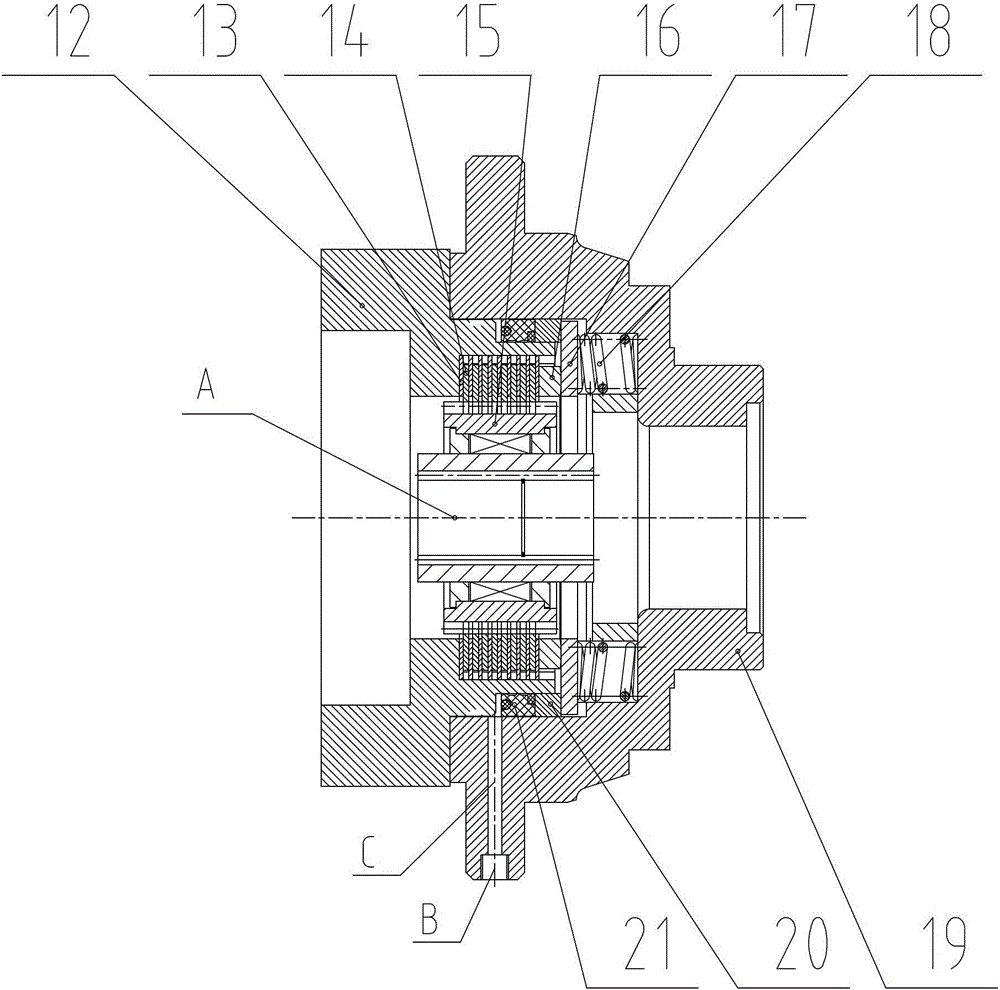

[0036] The following will be based on the attached Figure 1-3 And embodiment technical scheme of the present invention is described further.

[0037] Such as figure 1 As shown, the winch of the present invention is mainly composed of a clutch brake device 1, a left bracket 2, an input shaft 3, a first bearing 4, a planetary reduction device 5, a reel 6, a second bearing 7, a bearing 8, and a support shaft 9 , bolts 10, support cover 11 and other components.

[0038] Both ends of the reel 6 are equipped with the first bearing 4 and the second bearing 7. The planetary reduction device 5 is placed inside the reel 6 and installed together with the reel 6 through bolts 10. The clutch brake device 1 and the left bracket 2 pass through The bolts are installed together and the reel 6 is supported by the first bearing 4, the support shaft 9 and the right bracket 8 are installed together by the bolt and the reel 6 is supported by the second bearing 7, and one end of the input shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com