Rotating platform for tire conveying line

A conveying line and rotary table technology, applied in the field of conveying equipment in the production line, can solve the problems of low conveying efficiency, low degree of automation, and high labor intensity of workers, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

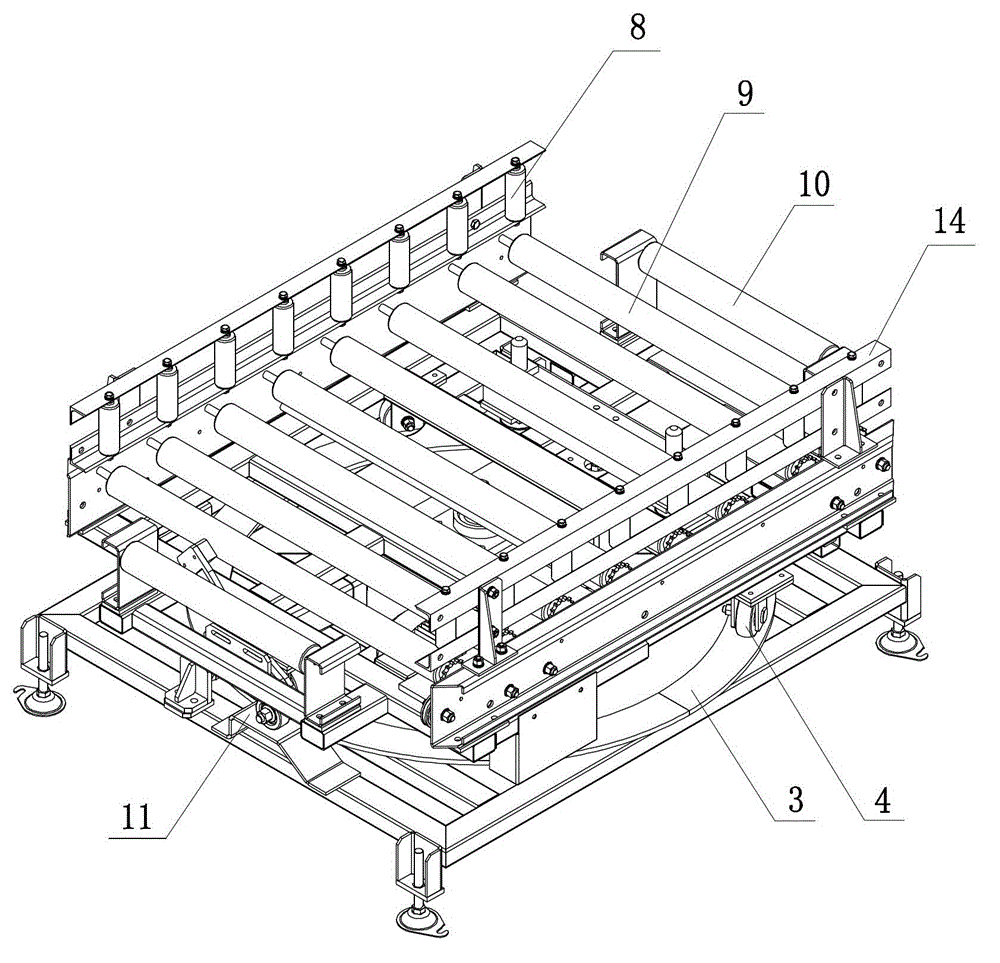

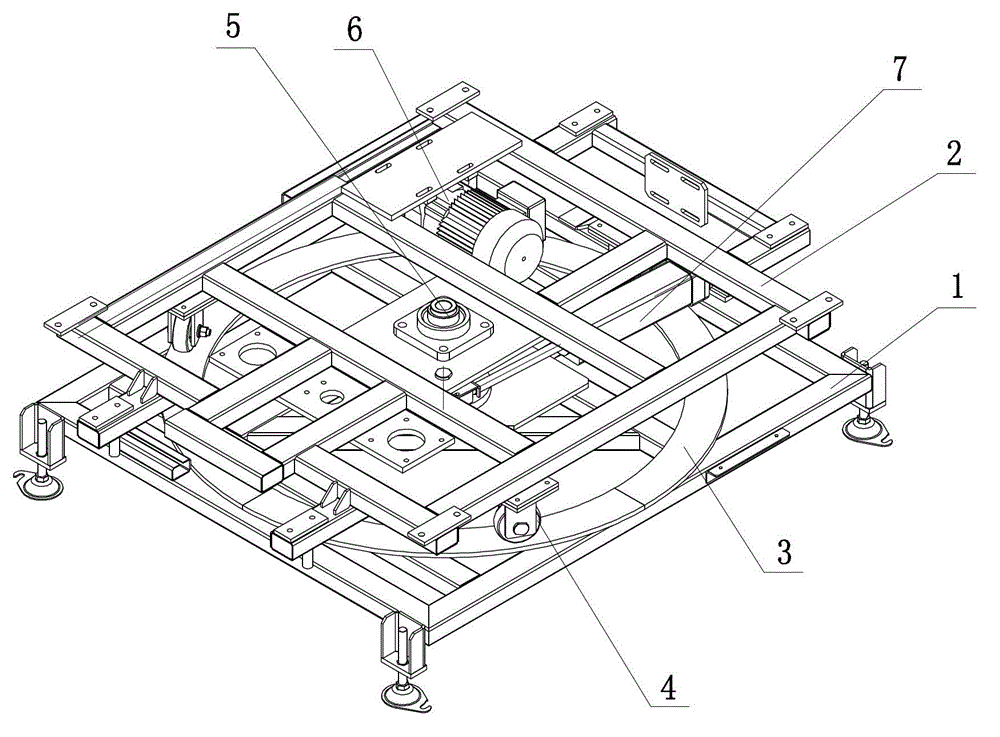

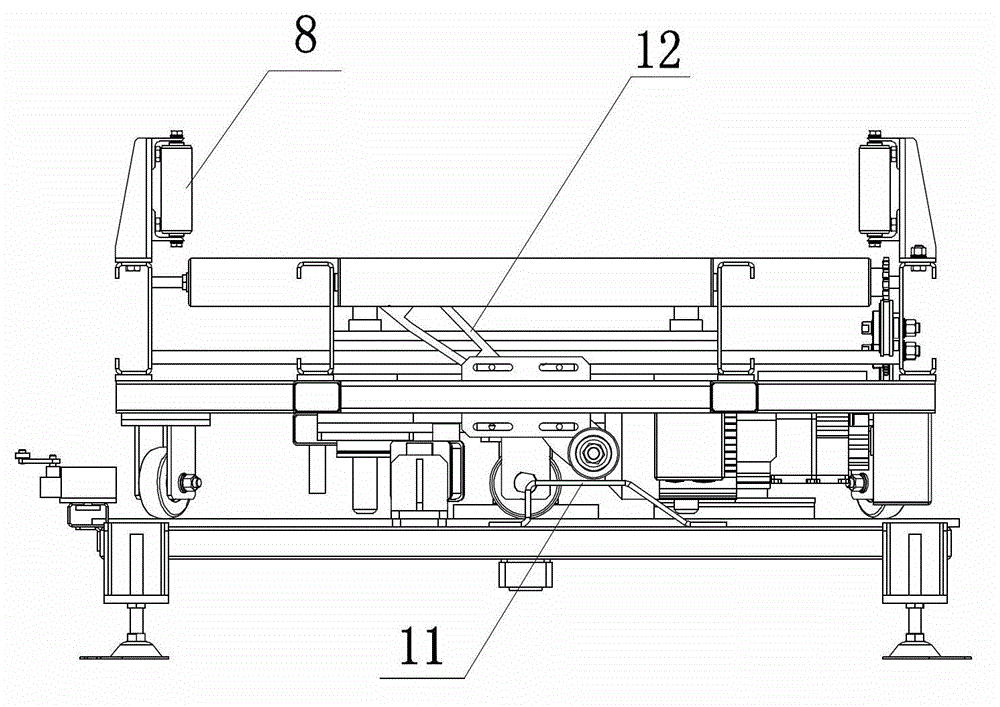

[0020] Such as figure 2 or image 3 As shown, a rotary table of a tire conveying line includes a base 1, a support frame 2 and a conveying assembly, the conveying assembly is fixed on the support frame 2, and a A driving device for driving the support frame 2 to rotate, a balance device for maintaining the rotation balance of the support frame is also provided between the support frame 2 and the base 1, a movable stopper 12 is provided at the front end of the transport assembly, and the movable The lower part of the stopper 12 is vertically connected to the support frame 2 by the movable shaft, and the base 1 below the movable stopper 12 is fixed with a stop block 11. When the support frame 2 has not rotated, the movable stopper 12 The bottom is on the blocking block 11. At this time, the upper end of the movable blocking device 12 is lower than the conveying surface, so as not to affect the conveying of the tire. When the tire is conveyed, the support frame 2 rotates, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com