Large-size cross beam mounting method

An installation method and beam technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult positioning and difficult positioning, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

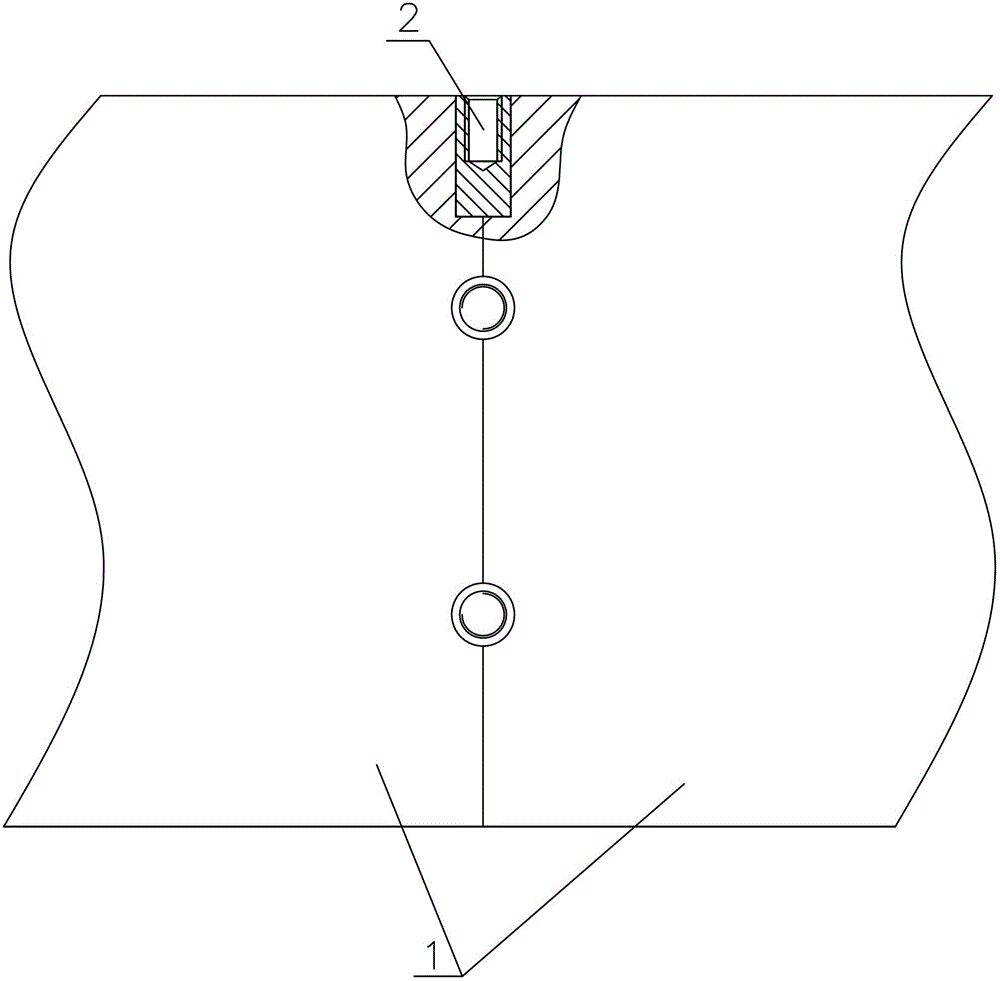

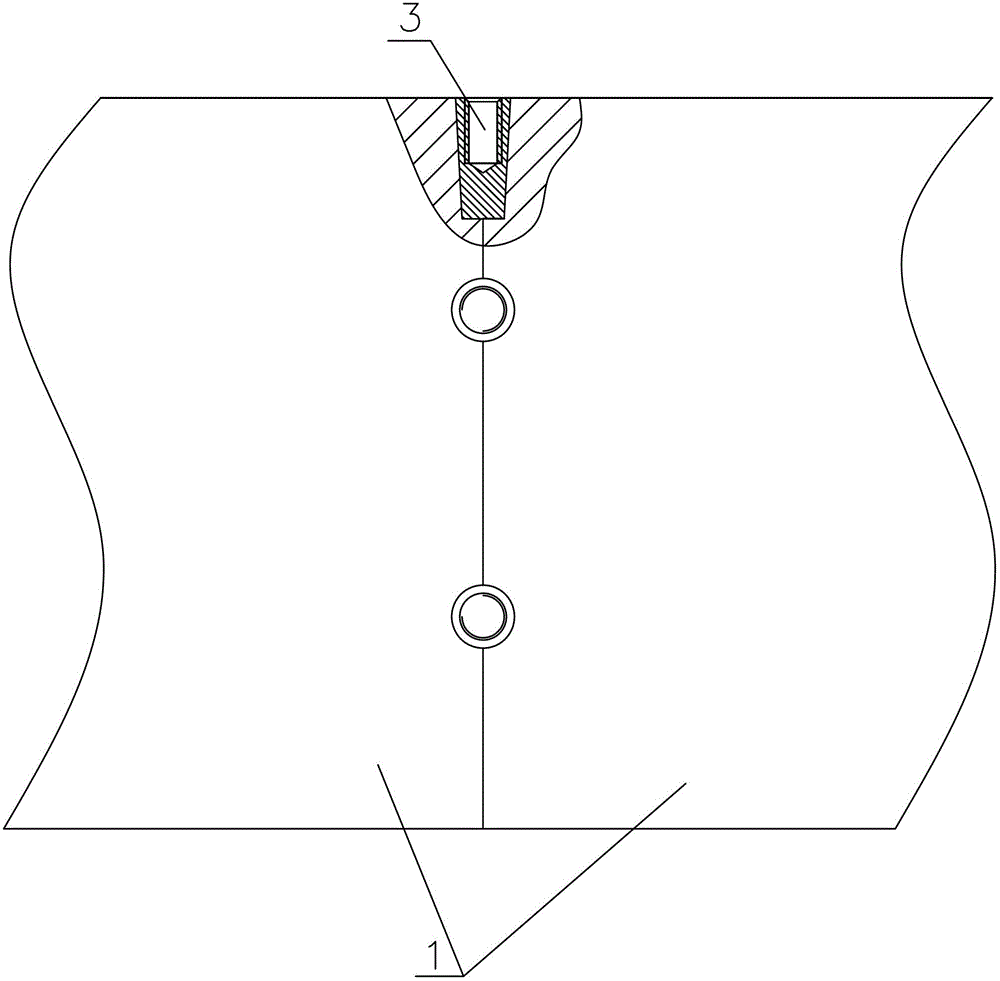

[0021] refer to figure 1 figure 2 , when installing on site, the first is the pre-installation of the ground, butt the two beams on the ground, adjust the upper surface of the two beams and the left and right sides to align with each other, and then install guide rails and racks on both sides of the two beams. The connecting plate is fixed between them; the upper end surface of the beam and the left and right end surfaces have semi-cylindrical holes, and the semi-cylindrical holes of the beam at the butt joint are spliced to form the entire cylindrical hole, and a cylindrical pin is driven into the cylindrical hole for positioning;

[0022] The following is the installation work in the air. When hoisting the beam to the robot support, remove the guide rail, rack and connecting plate at the joint of the beam, and take out the cylindrical pin at the same time, separate the two beams and lift them up; The crossbeams are slowly approached for docking, and the cylindrical pins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com