Automatic double-station screw assembly and disassembly mechanism

A loading and unloading mechanism and double-station technology, which is applied in the direction of metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of unable to meet the requirements of the manufacturing industry, increase the working cycle, and low operating efficiency, and achieve simple structure and high drilling speed. Fast, low overall cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

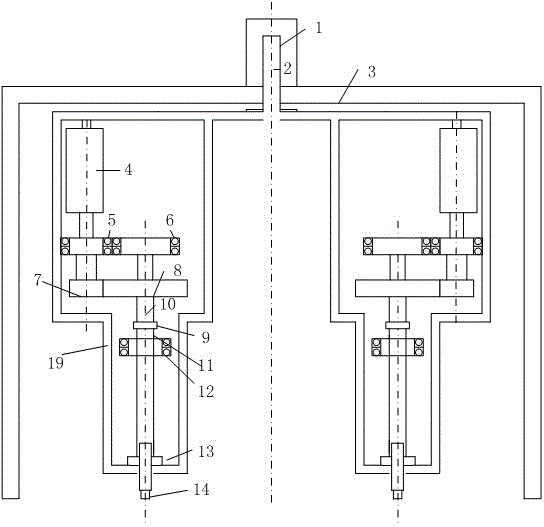

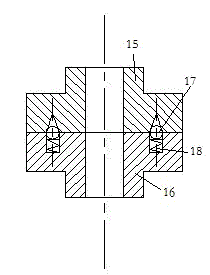

[0013] like figure 1 As shown, a double-station automatic screw loading and unloading mechanism, the device is a left-right symmetrical structure, including a hydraulic device 1, a piston rod 2, a frame 3, a station outer frame 19, a DC motor 4, a first bearing 5, a second Bearing 6, driving gear 7, driven gear 8, anti-torque device 9, first shaft 10, second shaft 11, third bearing 12, force sensor 13, screwdriver head 14 and third shaft 19; the hydraulic pressure The device 1 is fixed on the frame 3, the upper end of the piston rod 2 is connected with the hydraulic device 1, and the lower end is connected with the outer frame of the left and right stations; the DC motor 4 is fixedly installed on the outer frame of the station, and the DC motor 4 The output shaft is supported by the first bearing 5 and connected to the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com